In April 2025, the Japanese electronics group Kyocera demonstrated a solution for processing electrolytic capacitors with radial connections using reflow soldering rather than wave soldering. This involves placing the capacitor in an IDC-based intermediate holder. In addition, the holder makes it possible to arrange components in two levels on the carrier.

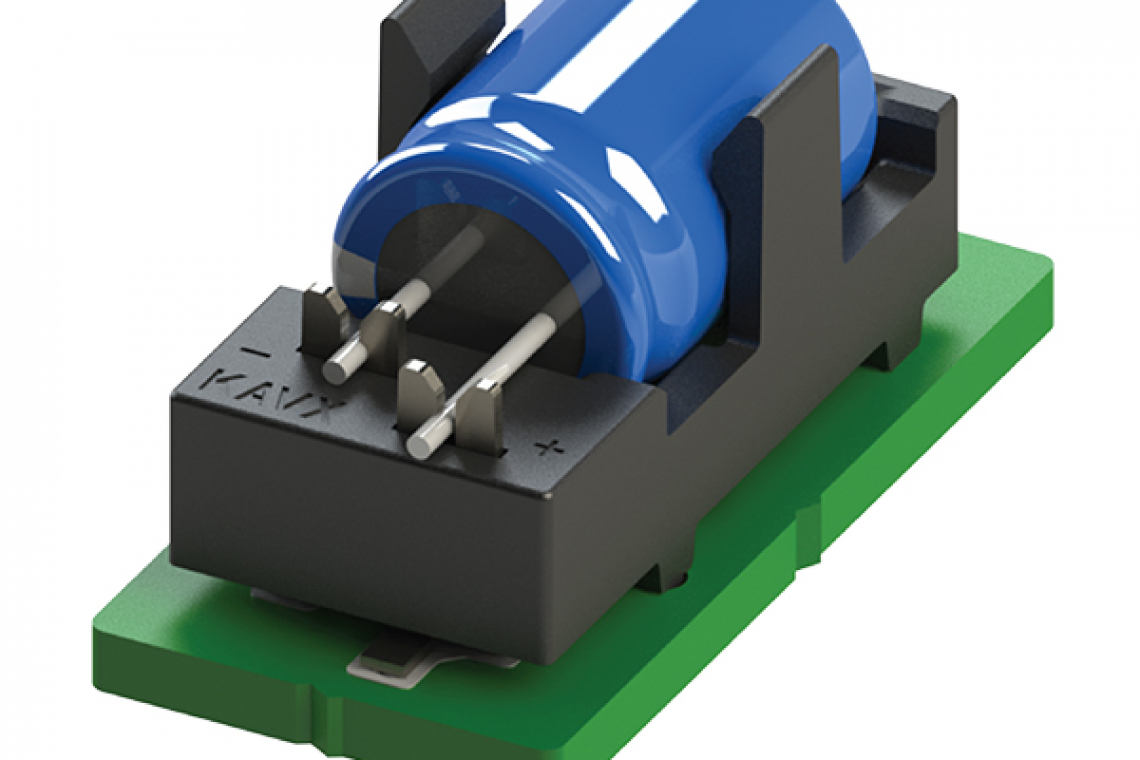

Kyocera AVX is launching a special product that allows the indirect installation of electrolytic capacitors with radial connections on the PCB safely and efficiently without having to solder them directly to the PCB. This gives the user the opportunity to eliminate manual soldering and improve production efficiency. The assembly process can be fully automated. This is achieved by using an IDC connector in SMD design (illustration). But the solution offers even more advantages:

- High temperature stresses caused by the soldering process can be avoided, which is particularly favorable for sensitive components

- Defective capacitors can be easily replaced manually without a soldering process, which facilitates repairs or the electrical balancing of circuits

IDC principle

IDC stands for Insulation Displacement Connector. Originally, such IDC connectors were realized as insulation displacement connectors. They were often used to connect ribbon cables or other multi-core cables to the board quickly and without stripping the individual wires. Kyocera's innovation now enables the transition to reflow soldering.

The SMT Capacitor Holder of the 9115-000 series can handle a maximum current of 10 A and a DC/AC voltage of up to 300V. The working temperature range is -40°C to +85°C. Areas of application can be, for example, the following: Vehicles, medical technology, lighting, industrial electronics, IoT, consumer goods, transportation and commercial vehicles, data technology/telecommunications, mobile devices, military/aerospace.

Universal applicability

The 9115 series SMT capacitor holder is designed to offer a wide range of applications and significant functionality. The component is compatible with a wide range of capacitors from 6.3mm to 10mm in diameter and allows the capacitor to be attached to the PCB only after the SMT process. The holder can simply be guided through the SMT process, after which the capacitor is snapped into the holder. At the same time, the leads are terminated via the IDCs without bending them. This can be done completely automatically. In addition, the 9115 series enables the PCB to be fitted with flat SMD components under the holder, as the distance between the holder and the board is 1 mm.