Pulse current electric rhodium plating

Artikelnummer: GALVANO-28034

Downloadbares Produkt

Pulse current electric rhodium plating

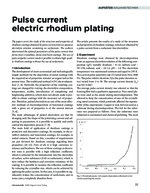

The paper covers the study of the structure and properties of rhodium coatings obtained by pulse current from an aqueous electrolyte solution containing no surfactants. The authors determined the optimal parameters of the pulse current that forms finer-crystalline, dense and hard coatings. The use of pulse unipolar current made it possible to obtain high-quality rhodium coatings without the use of surfactants.

1 Introduction: The development of more economical and technologically simple methods for the deposition of metal coatings with the required set of properties remains an urgent task at the present time. The traditional method is DC electrodeposition. Herewith, the properties of the resulting coatings are changed by varying the electrolyte composition, temperature, acidity, introduction of complexing and brightening additives, which does not always make it possible to obtain coatings with the necessary set of properties. Therefore, pulsed electrolysis as one of the most effective methods of electrodeposition of functional coatings with a given set of properties is of the utmost interest.

1 Introduction: The development of more economical and technologically simple methods for the deposition of metal coatings with the required set of properties remains an urgent task at the present time. The traditional method is DC electrodeposition. Herewith, the properties of the resulting coatings are changed by varying the electrolyte composition, temperature, acidity, introduction of complexing and brightening additives, which does not always make it possible to obtain coatings with the necessary set of properties. Therefore, pulsed electrolysis as one of the most effective methods of electrodeposition of functional coatings with a given set of properties is of the utmost interest.

2,70 €

Netto-Preis: 2,52 €

Enthaltene MwSt.: 0,18 €