BECOM Group, a globally active family business with roots in Burgenland, offers comprehensive services based on its own R&D expertise as well as its own products, including innovative sensor solutions and embedded system modules. The company's philosophy includes holistic sustainability, environmental and energy management.

BECOM has been working for industrial customers since 1984, initially as an extended workbench for electronic device manufacturers. The electronic engineering, manufacturing and service partner now offers everything from a single source, from the initial idea concept to development and validation through to series production as a one-stop store, thanks to international locations and partners for customers around the globe. The BECOM Group, headquartered in Hochstrass, Austria, now has nine production and sales locations. With a total of around 600 employees, 70 of whom work in engineering, BECOM generates an annual turnover of over €100 million. The R&D ratio is 5%.

Continuous development and capacity expansion

At the turn of the millennium, BECOM (Burgenländische Electronic Communication) began to develop and diversify in the area of customer industries. The target markets became the automotive, industrial and medical technology sectors. The first IATF certification took place in 2006. Production has also been taking place in Hungary since the early 2000s. 2011 saw the management buyout to the Bock and Klein families, supported by the Mittelstandsfonds. Since 2016, the time-of-flight specialist Bluetechnix has been part of the BECOM Group, which has expanded the business area to include innovative sensor solutions. Further sales and production locations were added in 2017 with the investment in IVP Group Germany GmbH.

In recent years, there has been increased investment in the area of embedded and sensor solutions in order to be able to react flexibly and with regard to a short 'time-to-market' for customers. Technological progress is supported by in-house research and development. Customers in the Embedded Systems division also benefit from a modular product range.

In addition to the three existing SMT lines, an additional line was invested in at the Hochstrass site this year. This will increase the possible output in the area of SMT assembly by 20%. The new line is optimally equipped to meet the demand for top quality, i.e. with, among other things:

- Solder paste printer followed by 3D SPI system

- High-speed dispenser

- Placer with LED centering function

- Reflow soldering system with vacuum chamber

- 3D AOI system

Continuous traceability and real-time process control are set up across the entire line.

Comprehensive range of services

From development to our own accredited test laboratories and process-optimized production through to backstage services, BECOM offers an ideal environment for successful projects. We offer everything from the concept to the series product. Manually assembled THT assemblies are just as possible as SMT precision assembly of millions of components every day. The production range includes

- SMT and THT production

- LED centering

- Press-fit technology

- Coating with CCI (Conformal Coating Inspection) and potting

- Fully automatic depaneling

- Device construction/box build

- Robotics

- Mechanical processing

- Inspection and testing (AOI, SPI, X-ray, ICT/flying probe test, functional test, boundary scan test, burn in/run in, EOL test)

Calibration, traceability and adapter construction as well as product-specific automation solutions (processing, assembly and test cells) round off the range.

Potting system and bonding unit

Potting system and bonding unit

EMC compliance and environmental testing

EMC compliance and environmental tests have been carried out for customers in the industrial, railroad, automotive, telecommunications and IT sectors for over a decade. These are based on the ISO/IEC 17025 accredited test laboratories and the accompanying support with design solutions from BECOM. This offers much more than just measurement technology: Results are interpreted directly on request and solution and design proposals are made.

In the EMC test laboratories, there are several absorber cabins covering around 1000m2. These include one that enables 4 m height scans and two absorber cabins with test load stands for motor outputs of up to 32 kW and measuring distances of 3 m and 1 m respectively. The full compliance CISPR 25 anechoic chamber is 6 m x 5 m in size. A shielded cabin for power-related RF tests and a pre-compliance absorber cabin for small test specimens round off the range. All test stations are equipped with modern measuring equipment.

The climate test laboratory includes temperature and climate chambers for temperature tests from -70 °C to +180 °C, tests at 0 % to 100 % relative humidity, temperature shocks from -75 °C to +200 °C and climate stress screenings with temperature gradients of up to 15K/min. High-performance measuring and testing equipment for ESD, HF, electronic and other tests is also available here.

The EMC laboratory is constantly being expanded. A second EMC location in the Graz region for applications in the field of e-mobility is currently being evaluated.

Versatile sensor solutions - embedded 3D ToF cameras according to customer requirements

In addition to its own products 3D Time-of-Flight cameras, System on Modules and software, BECOM also offers customer-specific solutions.

The 3D ToF cameras provide depth information and intensity data. An active illumination module emits modulated infrared light for this purpose. The light reflected by the object is projected onto the 3D camera IC via the lens. The distance data from the ToF IC to the object is calculated individually for each pixel, taking the phase shift into account. The result of a measurement cycle is a 3D point cloud containing intensity data for each pixel. BECOM products perform up to 160 measurement cycles per second. Their high performance and robust design make them ideal for a wide range of applications.

An innovative example is the TOREO - P650. A new multi-camera solution in an IP 67 housing for applications where stereo or ToF alone is not enough. The intelligent depth sensor IC provides depth information and gray scale image data for each pixel. Two RGB sensor modules provide a color data stream. The data is collected by an NVIDIA Tegra TX2 processor module, which calculates stereoscopic 3D data from the RGB modules. The range is up to 5m indoor and up to 3m outdoor with a FoV of 60°. The software with AI requires only 200 images for training (deep learning).

As a solution provider, BECOM not only supplies commercially available cameras but also embedded 3D ToF cameras optimized for special applications according to customer requirements.

BECOM products are used in automation and logistics (handling parcels and pallets, detecting volume and shape, checking fill levels on shelves), robot systems and driverless transport systems (navigation and obstacle detection), automotive technology (interior and driver monitoring, gesture control), care (fall detection in hospitals and care homes), building technology and security systems (detecting people, access control).

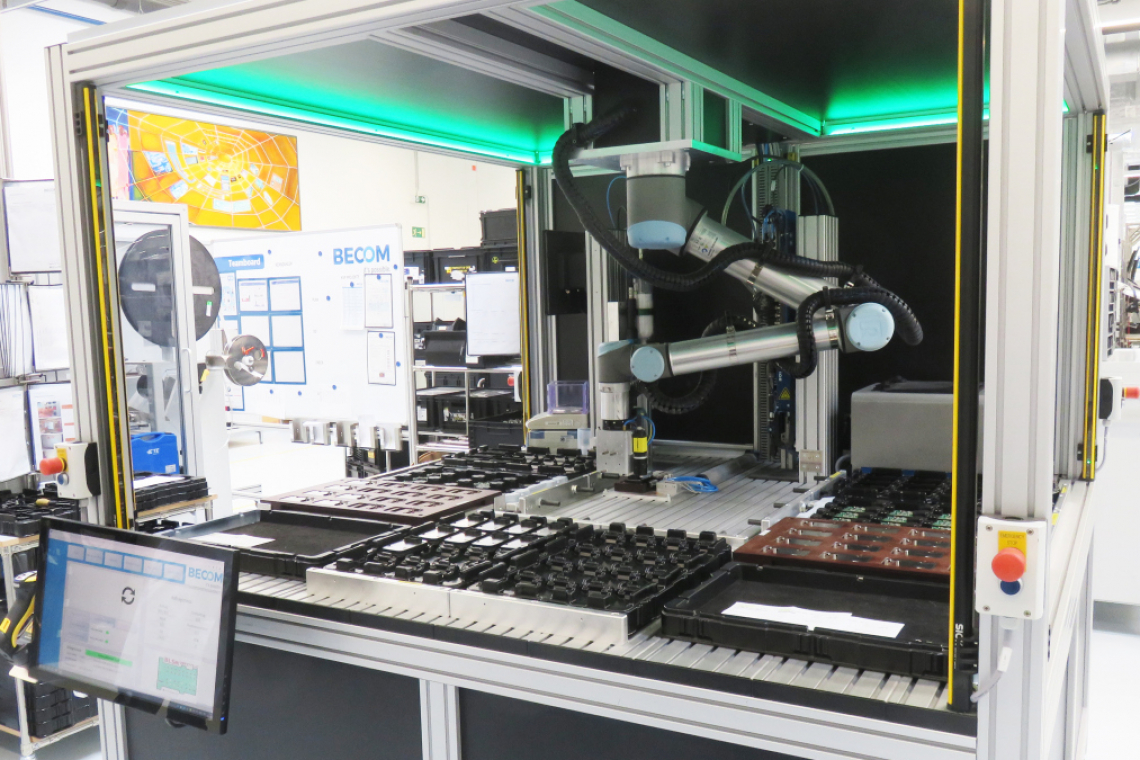

Product-specific assembly cell

Product-specific assembly cell

Vision and outlook - technology partner with a vision for electronics

DI Roman Bock, MSc, member of the management board and co-owner of BECOM, gave an outlook on the further development and vision of the company based on its history. The vision is to be a technology partner with a broad electronics base and foresight, i.e. top sensor technology with leadership in the field of 3D ToF by using the latest chips and turning them into products as well as developing customized embedded solutions according to customer requirements. BECOM intends to remain a global and sustainable family business with worldwide production sites in the electronics sector. The areas of responsibility are divided within the Bock family, which is the sole owner.

BECOM has been the sole shareholder of BECOM Systems GmbH since the beginning of the year. The plan is now to fully integrate it into the group in order to increase added value for customers and increase the depth of added value for BECOM. Customers will be offered complete solutions including validation and industrialization. Teams of experts find innovative solutions to customers' challenges. Highly efficient production with automated processes and innovative logistics make BECOM the ideal partner. This is complemented by development support, design solutions, testing by EMC experts, project and material management and after-sales services such as spare parts, end-of-life and obsolescence management. The focus is on the entire, complex product life cycle (PLC). And the entire product realization process is standardized from the moment the customer places the order.

Current situation

The coronavirus pandemic has also had an impact on BECOM. Initially, there were slumps in the automotive sector in particular. Many new projects were then launched, which are now leading to strong increases in sales. The core workforce was retained during the crisis, which is why these enormous increases in turnover were possible. And without the supply problems for components, even more would have been possible. As there is still no sign of a major easing of the situation for components, BECOM has created a risk components task force. Total sales of €150 million are expected by 2024/25, a large proportion of which is already covered by projects. Growth is accompanied by ever-increasing customer demands for shorter lead times and more documentation. Complexity is also increasing. Over 1500 different products are currently being realized for around 50 customers, which are made up of a total of over 15,000 different components. At present, 30 new customer products are in the NPI phase. The required specialist personnel is also an issue here, but not yet a major problem due to the HTL Pinkafeld technical college located in the region.

What makes BECOM attractive to customers, in addition to its certifications and professionalism, is above all the company's flexibility and ability to realize development times within a year, even for highly complex new products from the specification sheet. In addition, the Hochstrass site isCO2-neutral(zeroCO2 emissions). No more fossil fuels are used there either. This is also planned for all other sites in the coming years. In addition, the circular economy is practiced wherever possible by using reusable packaging instead of disposable packaging. A PV system with 150 kWp is in operation in Hochstrass. There are plans to double this. The head office has achieved a 57.6% reduction in effective energy consumption over the last 10 years and made extensive investments in future technologies (e.g. smart controls, LED lighting, PV systems, etc.) and implemented a waste management concept (e.g. water dispensers instead of bottles). More comprehensive data can be found in a sustainability report in accordance with the GRI standard. With an R&D ratio of 5%, BECOM is constantly investing in the future.

Strong engineering with experts

BECOM supports its customers with a great deal of expertise right from the brainstorming stage and throughout the entire PLC. In Hochstrass and Vienna alone, 70 people work in the development department. These include experts in embedding, ToF, LED technology, communication interfaces and processes. As Andreas Prenner, Head of Development at BECOM, explained, the engineering portfolio ranges from the customer's specifications to the requirements specification, in which the requirements are set out, through to process and test development. Tools from Mentor and Altium are used for development. The standardized product development process is supported with a tool from Confluence. Examples of the products developed include

- LED lighting electronics (upstream electronics for BMW - Tier 1 partner)

- 3D camera systems (ToF technology, high-speed digital design and processing, FPGA, optics)

- Embedded systems (seat massage systems, immobilizers, VPN routers, driver electronics for LED applications)

- Power electronics (generic power supply platform, DC motor control 120 A)

- Medical technology (non-invasive medical electronics, transcranial brain stimulator).

In the past, 80% of development was automotive-related, but today this figure is only around 50%. The remainder is divided between industrial and medical technology.

The sensor technology developments and services for customers reflect the innovative strength and high performance and BECOM is a reliable and sustainable partner. From project and material management to after-sales services, customers always receive more than just a product.