The Industrial Line, also known as IDL, is a new test adapter from the company 'ELOPRINT'. The IDL product line is designed for robustness and complements the portfolio of the existing BAL, PRL and POL lines.

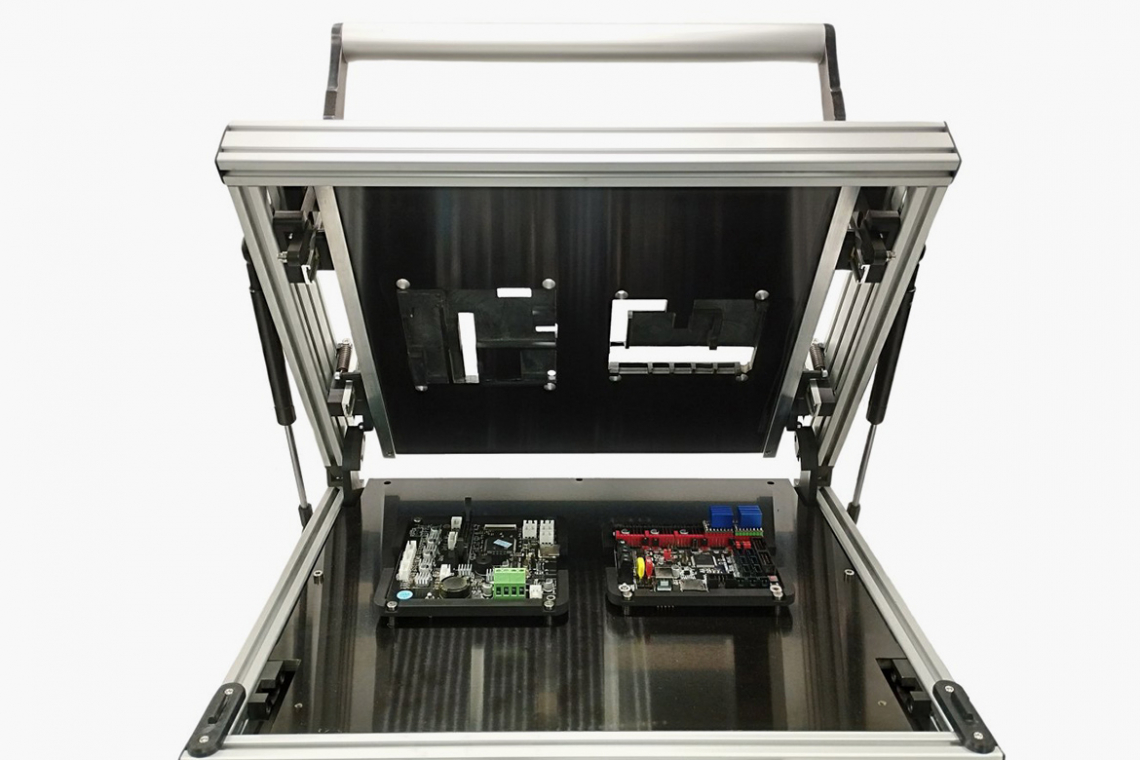

Image: ELOPRINTThestable frame made of aluminum strut profiles forms the basic structure of the system and ensures stability and scalability. The IDL is available in two standard sizes with a maximum test area of 200x200 mm or 300x300 mm, allowing a wide range of PCB sizes to be covered. In addition, the Industrial Line has been designed so that it can also be manufactured in special sizes.

Image: ELOPRINTThestable frame made of aluminum strut profiles forms the basic structure of the system and ensures stability and scalability. The IDL is available in two standard sizes with a maximum test area of 200x200 mm or 300x300 mm, allowing a wide range of PCB sizes to be covered. In addition, the Industrial Line has been designed so that it can also be manufactured in special sizes.

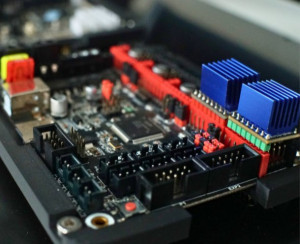

Inside the adapter, the CNC-milled needle bed ensures an exact arrangement of the test needles. This enables reliable electrical contacting of even the smallest test points. A spring-loaded carrier plate protects the needles when inserting the PCB and ensures their longevity. The test adapter has a special closing mechanism. A rotating movement causes the hold-down device to fold backwards when open so that the test specimen can be inserted unhindered. When closing, the upper frame first folds downwards before switching to a linear movement and gently pressing the test specimen onto the test contact pins.The mechanism also locks the front when closing, which prevents the hold-down device from bending upwards even under high contact pressure. This enables up to 1,000 test points to be contacted.

Precise alignment can be achieved using catch pins or via the outer geometry of the PCB. To protect the test probes, the PCB is first placed on the spring-loaded carrier plate during insertion and only comes into contact with the test probes when the adapter is closed. Instead of the hold-down device, a second needle bed can be integrated for double-sided contacting. An individually specified electrical interface to the measurement electronics is part of the adapter and permanently connected to the needle bed. An additional internal transfer interface between the needle bed and the connector panel is not required. This reduces complexity, increases signal integrity and offers the option of defining individual interfaces to the measuring electronics for different needle bed inserts.

Thanks to the tool-free exchange of the needle bed and the hold-down device, the test adapter enables fast configuration. The ability for double-sided contacting extends the range of testing options. Components such as switches, display elements, switching contact probes and sensors can be integrated into the IDL to detect the presence of the test object.