Integrated metal/plastic injection molding (IMKS) is a process developed at RWTH Aachen University for the production of complex plastic components with a conductive interior. A specialist for lead-free solders is involved in the development. The solders create conductor paths and electronic component connections in the injection-molded parts.

Since switching to lead-free soldering technology in 2006, nickel-doped solders have become established in all soldering processes in electronics production: as solid solder for wave and selective soldering systems, as powder in SMD solder pastes for reflow soldering processes and as flux-filled solder wires for manual and automated piston soldering. In addition to these 'conventional' fields of application, the NiGe solder fields Sn100Ni+ and Sn96Ag+ have found a new area of application: In the 'Integrated Metal/Plastics Injection Molding' (IMKS) process designed by the Institute of Plastics Processing (IKV) at RWTH Aachen University and further developed with the support of injection molding machine manufacturer KraussMaffei and the Heinze Group, they are used to produce the integrated electrical and mechanical connections of electronics. The manufacturing process produces electrically functional, complex plastic components in a single-stage injection/pressure molding process. The foundations for this process have been laid in various IMKS projects since 2014. Since then, Felder GmbH has also been a member of the project-accompanying committees.

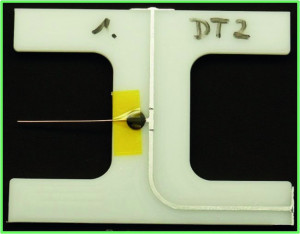

Fig. 2: Specimen from the 'IMKS contacting' project [2]

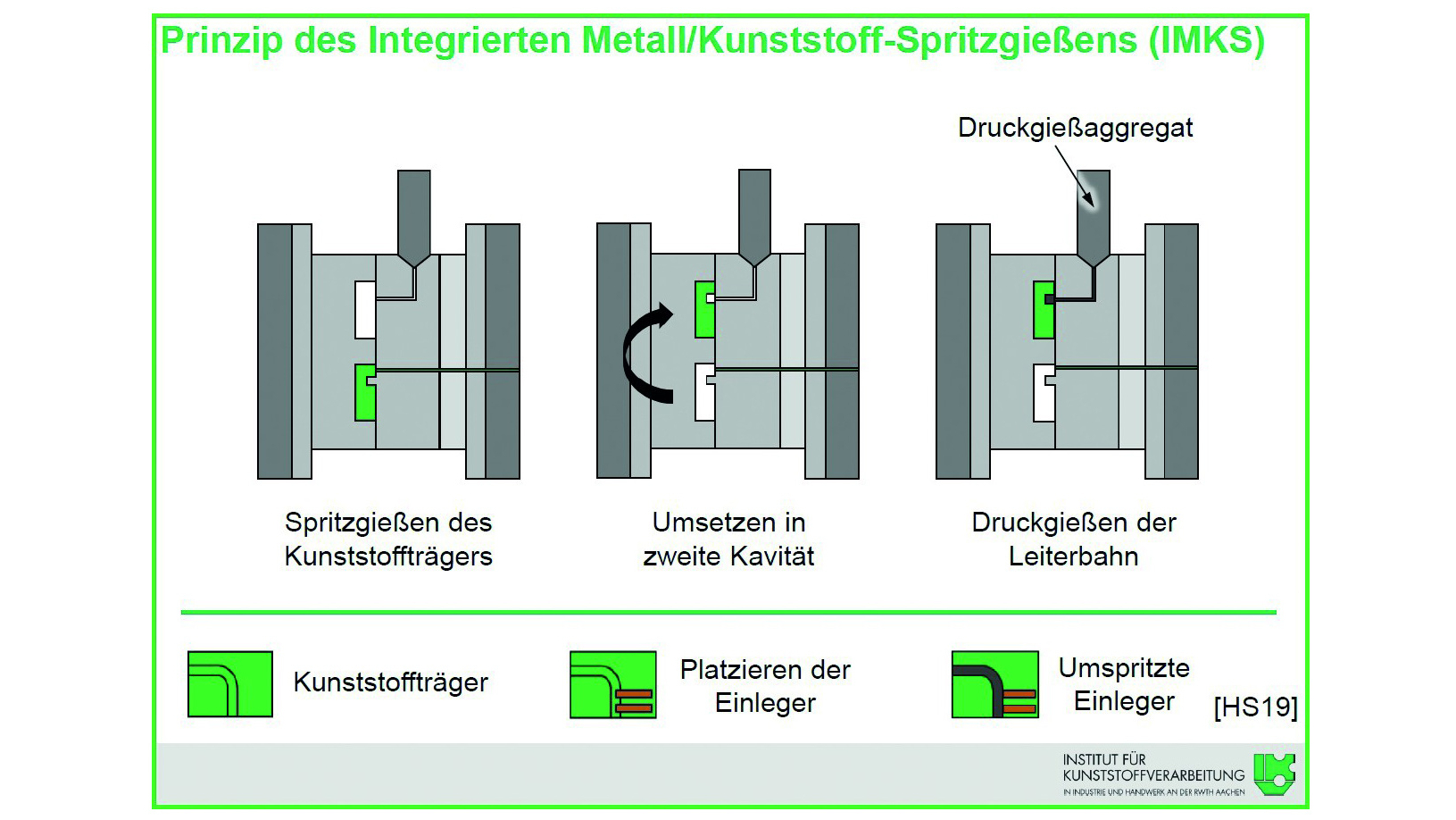

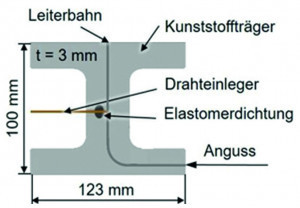

Here is the basic procedure in the IMKS process: First, a plastic body (housing, component carrier) is produced by injection molding. This is transferred into a second cavity within the mold, electronic components are placed (for this test setup a plain copper wire) and conductor tracks made of lead-free soft solder are injected into the conductor track channels provided for this purpose using the die-casting process. The main advantage of this method is that it shortens the process chain by eliminating the need for complex metallization or insertion processes for the electronic functionalization of plastic injection-moulded parts.

From the large number of conventional, lead-free solder alloys that have been established in electronic assembly production since 2006, three solders -

- Bi58Sn42 (melting point 138 °C)

- Sn96Ag+ (Sn96/Ag3/Cu0.5/Ni0.05/Ge0.01, melting range 217-219 °C) and

- Sn100Ni+ (Sn99.24/Cu0.7/Ni0.05/Ge0.01, melting point 217 °C)

- were selected as conductor materials. Initially, the alloy Bi58/Sn42 appeared to be optimal for IMKS due to its low melting and processing temperature. However, due to insufficient electrical conductivity and low bond strength to the thermoplastics tested, it was not considered further in the current IKV project 'IMKS contacting' [1].

Sn100Ni+ and Sn96Ag+ exhibited the highest strength values in the material combination with thermally conductive plastic in the tensile tests carried out on the sample bodies(Fig. 2). The highest electrical conductivity over the entire length of the conductor was also measured with Sn100Ni+ (also in combination with thermally conductive plastics). The high purity of the Felder NiGe solders and the low oxidation in the molten state reduce casting defects and ensure reliable connections to the contacts. The optimized nickel content in the solders demonstrably and significantly extends the service life of the system parts in contact with the molten metal.

The IMKS process is now ready for series production and corresponding commercial production facilities are available. Nevertheless, research on this topic is continuing at IKV: optimizations are being carried out on the conductor track layout and the contacting of inserts in order to create further potential areas of application for this innovative technology.

www.ikv-aachen.de, www.felder.de

References:

[1] Full title: 'Analysis of the contacting of metallic inserts with low-melting metal alloys in integrated metal/plastic injection moulding'

[2] Images: Hopmann, C.; Sturm, I.: Langzeitbeständige Leiterbahnen - Prozesssimulationen zum Optimieren des Integrierten Metall/Kunststoff-Spritzgießens. Plastverarbeiter 70 (2019) 10, p. 96-99