If THT, SMT and THR do not meet the requirements of the application, press-fit technology can be the solution. This is the case when, for example, high vibration resistance, high performance or extreme technical load safety is required.

Kraus-HW manufactures punches and counterholders with its own CAM machining centerThisincreasingly applies in different ways in the automotive, railroad technology, aerospace and e-mobility sectors.

Kraus-HW manufactures punches and counterholders with its own CAM machining centerThisincreasingly applies in different ways in the automotive, railroad technology, aerospace and e-mobility sectors.

A recent customer project presented Kraus Hardware GmbH with extraordinary challenges: a two-part high-current connection was to be connected to the PCB using press-fit technology. The mechanics had to be set up in such a way that the high components (up to 65 mm) were not damaged.

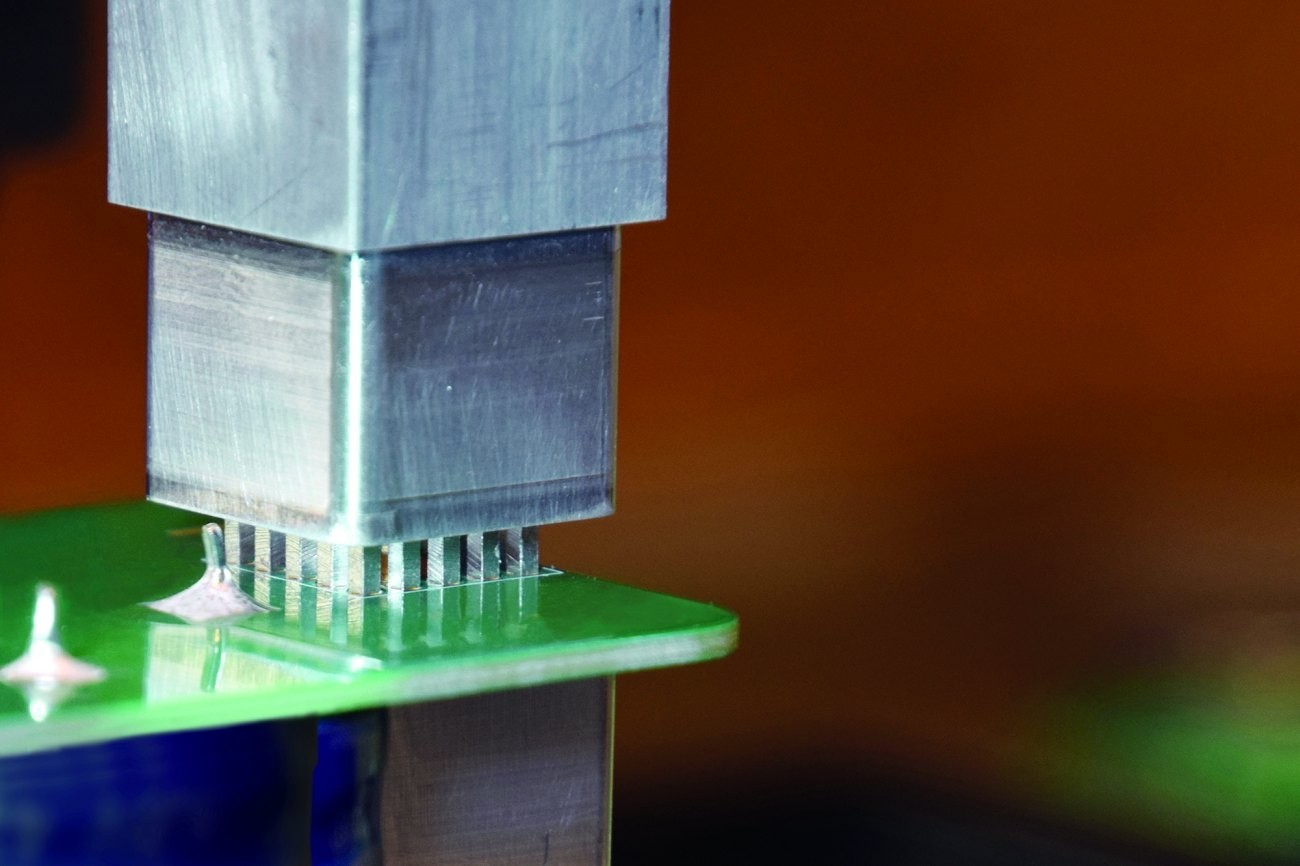

As Kraus-HW has been offering the possibilities of press-fit technology for years with its holistic in-house approach, the task could be completed immediately. A customized counterholder and punch were designed and manufactured in the in-house fixture construction department to compensate for the far above-average height difference to the PCB. Both pressing and press-fit tools were precisely milled and drilled from solid metal using the in-house CNC machining center and then sent for further production. The stamp picks up the small connection component and the PCB is positioned between the counterholder and the stamp. Press-fitting then takes place in just a few seconds.

The PCB is positioned between the stamp and the counterholder. The subsequent press-fit takes place in a matter of seconds

The PCB is positioned between the stamp and the counterholder. The subsequent press-fit takes place in a matter of seconds

The other 'normal' THT electronic components are then soldered very quickly and with good solder penetration using a Vario mini wave. "The entire production process is configured completely in-house and therefore offers the customer a high level of product quality, delivery reliability and price guarantee," emphasized Managing Director Andreas Kraus.