As component sizes shrink and placement density increases, many manufacturers are rethinking the size of their solder paste powders. While pastes with finer particle sizes - such as Type 5, Type 6 or even Type 7 - offer improved print definition and fewer defects in miniaturized components, they also bring new challenges in terms of process control and cost.

This paper examines when it makes sense to switch to finer solder pastes. It provides insights into powder classification, stencil design and print transfer efficiency, as well as best practices for successful implementation.

Understanding the classification of solder paste powder

Solder paste powders are classified by particle size according to IPC J-STD-005, where only 80% of the particles need to fall within a certain range (see Table 1). This leaves considerable room for variation between manufacturers, which becomes more critical the smaller the powder size.

| Type | ≥ 80 % between | < 10 % between | < 0.5 % greater than |

| Type 3 | 25-45 µm | 45-60 µm | 60 µm |

| Type 4 | 20-38 µm | 38-50 µm | 50 µm |

| Type 5 | 15-25 µm | 25-40 µm | 40 µm |

| Type 6 | 5-15 µm | 15-25 µm | 25 µm |

| Type 7 | 2-11 µm | 11-15 µm | 15 µm |

Challenges in the reduction of solder paste powder

Reducing to a smaller powder involves compromises, especially with the smallest powder sizes. These are as follows:

- Smaller powders are more difficult to produce and therefore more expensive.

- Smaller powders have a higher surface to mass ratio and are therefore more susceptible to oxidation. This shortens the shelf life and makes them more sensitive to process parameters. Nitrogen reflow is required for type 6 and smaller.

- The manufacturing processes differ from supplier to supplier. Therefore, there can be significant differences in quality with regard to the spherical shape of the particles and the particle size distribution of a particular powder size. These deviations can lead to unexpected problems and defects.

- With finer powders, it may be necessary to adjust the stencil design to avoid problems such as stencil clogging or insufficient paste release. Stencil thickness, aperture size and wall smoothness must be taken into account.

- In general, the finer the powder, the smaller the process window. This means that settings such as squeegee pressure and speed must be selected very carefully.

| Type | Minimum aperture diameter |

| Type 3 | 225 µm |

| Type 4 | 190 µm |

| Type 5 | 125 µm |

| Type 6 | 75 µm |

| Type 7 | 55 µm |

The 5-ball rule and its effects on stencil design

A general rule of thumb for the design of stencil openings is the '5-ball rule'[*]. The rule states that the smallest stencil opening should hold at least five solder powder particles across its diameter. This rule also indicates when a smaller paste size may be required.

While this rule is useful, it has its limitations - especially with ultra-fine types. Actual printability also depends on the area ratio (aperture area vs. stencil wall area) and paste rheology. In some cases, a finer paste size may be required even though the 5-ball rule is satisfied for a larger size. In other cases, a manufacturer may use a larger paste size even though some openings are close to or just above the limit recommended by the 5-ball rule.

Arguments for sticking to the largest possible size

Despite the obvious advantages of finer powders, downsizing is not always advisable. In borderline cases, process optimization with the larger paste size may be sufficient.

For example, suppose you need to print boards whose smallest components are 01005. The stencil openings recommended by IPC for these components are 175 x 250 µm, which may be outside of what can be printed with type 4 paste (≥ 190 µm).

However, with some ingenuity, it is also possible to use a rounded square aperture design with a side length of 190 µm or slightly larger for these components. This aperture shape maximizes volume in tight spaces while improving transmission efficiency.

In this scenario, transfer efficiency can be further maximized by using a nano-coated 4-mil or even 3-mil stencil. Therefore, if your smallest components are 01005, type 4 paste can still work, provided you achieve the required process control. At the same time, depending on the board design, equipment and materials available, better results can be achieved with Type 5 paste in such a scenario.

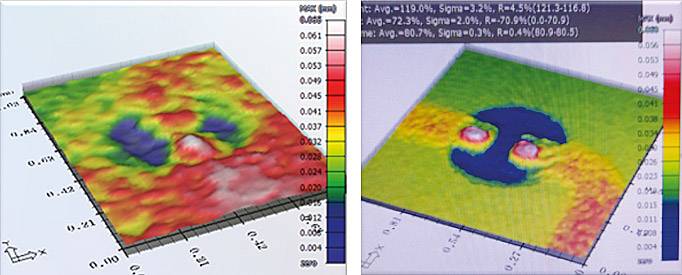

Comparison of resolution before the SPI upgrade (left) and after the SPI upgrade (right)

Comparison of resolution before the SPI upgrade (left) and after the SPI upgrade (right)

Process control requirements for finer solder pastes

The transition to finer solder pastes such as Type 5, Type 6 or Type 7 brings with it a number of requirements for the print and reflow process. These pastes are often used in assemblies with smaller components and more compact layouts, where the likelihood of defects increases and the ability to fix them afterwards decreases.

Defects such as bridging, insufficient solder volume or head-in-pillow solder joints are more difficult to detect and rectify in fine-pitch assemblies. The components are often too small for rework, which means the focus is on prevention rather than correction. In addition, the sheer number of solder joints in dense assemblies increases the likelihood of failure, even with a relatively low defect rate. For this reason, even small deviations in the printing process or reflow profile can further impact yield and reliability.

Stencil design plays a crucial role in ensuring consistent paste delivery with finer powders. Thinner stencils - typically in the 3-4 mil (0.762 µm -0.1016 µm) range - are preferred for Type 5, and stencils down to 1 mil (0.254 µm) can be used for Type 6 and finer. Aperture geometry must be carefully optimized to ensure sufficient solder volume without risking clogging or sagging. Rounded or square shapes, smooth aperture walls and nano-coated surfaces have been shown to improve delivery and reduce variability. Laser cutting tolerances also become more important at these sizes, as even slight irregularities can affect the behavior of the paste.

During the printing process, squeegee speed and pressure need to be controlled more precisely than with coarser pastes. Lower print speeds allow for better opening filling, while pressure must be reduced to the minimum necessary to ensure clean wiping without deforming the stencil or pushing paste into unintended areas. Release speed and tear-off settings should also be fine-tuned to ensure a clean release, especially with tight clearances. Print performance is very sensitive to these parameters and even small adjustments may be required to accommodate different PCB designs.

The transition to finer pastes may also require investment in process equipment. For example, solder paste inspection systems must have sufficient resolution to measure deposits on a small scale. Similarly, advanced AOI and X-ray systems may be required for post-reflow inspection of ultra-miniature joints.

Another aspect is the control of environmental conditions. Finer pastes are more sensitive to changes in humidity and temperature, which can alter the rheology of the pastes or contribute to oxidation. In many cases, simply improving the stability of the printing environment can go a long way to achieving consistent results.

Reflow profiles also need to be adjusted. As finer powders have a larger surface area, they are more prone to oxidation, especially at elevated temperatures. Therefore, nitrogen reflow is typically recommended for type 6 and finer powders. During profile development, peak temperature, time over liquidus, ramp rate and cooling rate should be considered to ensure that the solder fully wets the pads and component leads while avoiding defects such as voids or grain coarsening. Special care must be taken in the soaking and ramping phases to allow complete activation of the flux and minimize sagging or spattering of the paste.

Ultimately, when using finer solder pastes, the process window becomes narrower and a greater degree of discipline is required. While the potential for high-quality, high-density assembly is greater with these pastes, the risk of errors increases with a lack of process control. Success depends not only on choosing the right materials, but also on fully optimizing the printing and reflow process to meet the requirements of the application.

Conclusion and recommendations

Miniaturization continues to challenge conventional printing processes. Type 5 solder pastes and finer pastes offer compelling advantages for small components and compact layouts, but also require more precise process control and come at a higher cost. Before switching to a finer paste, manufacturers should:

- Evaluate area ratio and stencil design

- Test transfer efficiency and print performance

- Evaluate oxidation risks and reflow atmosphere requirements

- Consider the impact on overall costs

In many cases, process optimization with a larger paste size can achieve the same result with fewer risks. However, if the application requirements cannot be met, downsizing with a carefully tested fine powder paste is a necessary step to improve print quality and yield.

References

[*] 'Requirements for Solder Pastes', IPC J-STD-005A, February 2012.