Applications of semiconductor circuits and components in power electronics, electronics for renewable energies and in artificial intelligence are real energy guzzlers. However, there is still a lot of research work to be done in order to achieve the energy savings that are urgently needed to stop the impending climate crisis. This is happening at Munich University of Applied Sciences, for example.

Richard Ganser is working on his doctorate in the laboratory for modeling at the Faculty of Applied Natural Sciences and Mechatronics at Munich University of Applied Sciences (HM).

There he is working on the Zeppelin project, which is funded by the German Research Foundation (DFG). The aim is to further develop ferroelectric hafnium and zirconium oxide - two materials that are causing a stir in semiconductor technology.

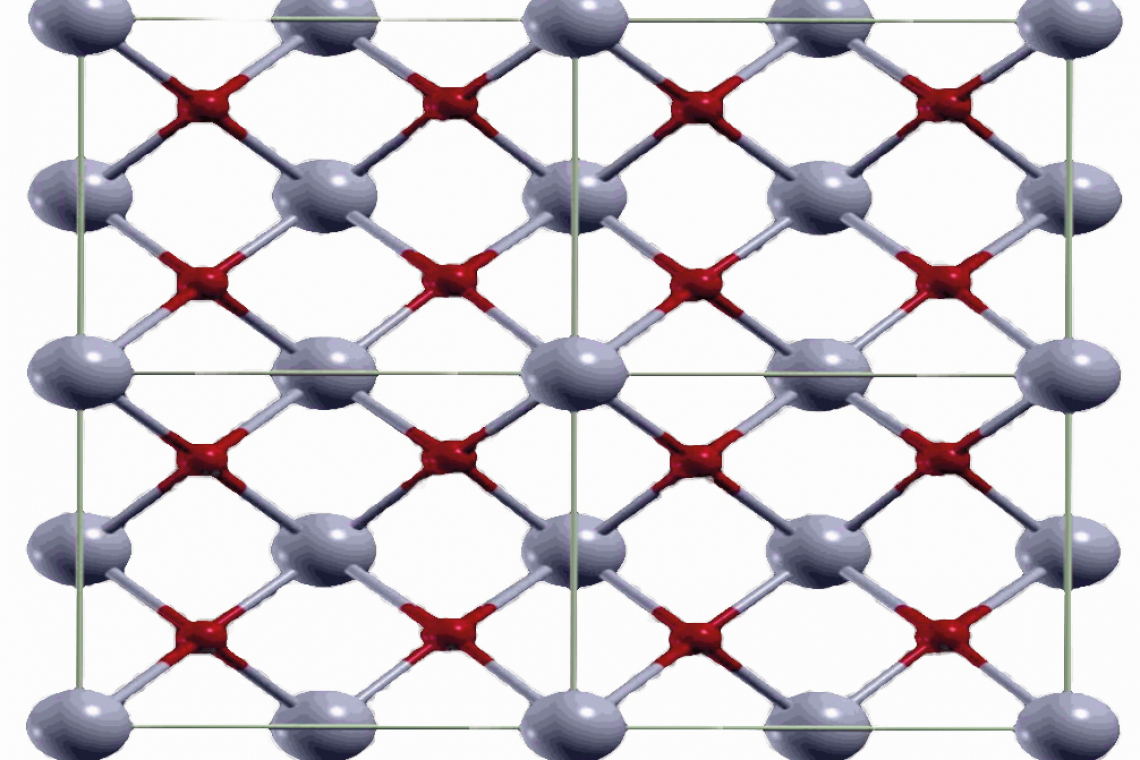

The Zeppelin project is investigating ferroelectric hafnium oxide (HfO2) and zirconium oxide (ZrO2). Both materials have long been used as dielectrics in semiconductor capacitors. Under the influence of an applied electric field, they can permanently change from the dielectric phase to the ferroelectric phase and remain in this state even after the electric field has been removed, similar to a magnet. These ferroelectric properties of permanent polarization can be used to map and permanently maintain a binary state (0 or 1), as with the well-known non-volatile data storage devices (SSD).

High remanent polarization

Hafnium oxide and zirconium oxide are characterized by a high remanent polarization, high dielectric constant, freedom from lead and silicon compatibility. The controllable dielectric, piezoelectric and pyroelectric properties of the material, which lead to particularly high performance figures, are very promising. The Zeppelin project will investigate the causes of these properties, optimize them and determine the key performance indicators of sensor and actuator components such as varactors, thin-film acoustic resonators and IR sensors.

To realize the function, thick layers in the order of 1 µm are required in some cases. In particular, the ferroelectric phase in these thick layers is to be stabilized or made accessible in a field- or temperature-driven manner. Another important aim of the investigations is to understand and control the phase composition. On the theoretical side, a dopant preselection is planned, the analysis of the kinetics of the phase transitions and the calculation of the piezoelectric and pyroelectric properties in comparison with experiments carried out.

The special properties of this material were discovered 15 years ago by Prof. Alfred Kersch at Infineon, then Quimonda, in Dresden, and he brought the research topic to the HM.

The Zeppelin project combines the experimental possibilities of the NamLab, a research institute of the TU Dresden, with the simulation capabilities of the HM, whereby the experiments are prepared and carried out in Dresden and the HM attempts to find the theoretical explanations for them.

Simulation method and insights gained

The simulation method used by Ganser, 'molecular dynamics with machine learning', uses neural networks that are trained with atomic material data derived from quantum dynamics. This makes it possible, for example, to simulate the influence of film thickness, grain size, temperature and doping on the crystal structure and thus on the material properties.

Hafnium oxide and zirconium oxide are currently used as dielectrics in all modern computer chips to store electrical charge in capacitors. Under certain conditions, the materials take on ferroelectric properties.

In the simulation, processes that accompany the formation of the material's polarization could be described in atomistic detail and temporally resolved for the first time. And on a scale of up to one million atoms, far more than the previous hundred.

The simulation has so far shown, among other things, that the ferroelectric phase can be stabilized depending on temperature, film thickness and grain size. For the first time, the phase transitions could be simulated on whole crystal grains. Furthermore, Ganser was able to use the simulation method to describe the conditions under which a change from the dielectric phase to the desired ferroelectric phase takes place and thus provide suggestions as to how the manufacturing processes would have to be adapted in order to enhance the desired properties.

Outlook for energy-saving AI

AI models such as ChatGPT are already changing the way we work and live. However, these models consume a huge amount of energy. American tech companies are therefore investing hundreds of billions in the construction and reactivation of nuclear power plants just to run the AI models. Research into the pioneering material, ferroelectric hafnium and zirconium oxide, offers the opportunity to significantly reduce energy consumption and thus create the basis for energy-saving AI models. However, further research is needed before the materials can be used on an industrial scale. Ganser is convinced that the main focus will certainly be on long-term stability and thus extending the service life of these components. In order to increase the number of possible switching operations in the component to such an extent that it has a target service life of around ten years, the number of possible polarization cycles - how often the material can be repolarized - must be increased considerably. Depending on the application, this corresponds to approx. 1010 polarization cycles. HM is also working on this topic.