The 'mother' of mounting techniques for electronic components on printed circuit boards, through-hole mounting, is on its deathbed according to some experts. Is it already as good as dead? This is disputed by other market researchers and industry insiders: on the contrary, THT will probably be with us for many years to come. It is only unclear what proportion.

THT, SMT and THR are the three main PCB assembly processes on which the production of electronic assemblies based on PCBs is essentially based. However, all three have significantly different shares in production, for both historical and technical reasons. Let's first take a look at the technical and technological differences.

Technical differences

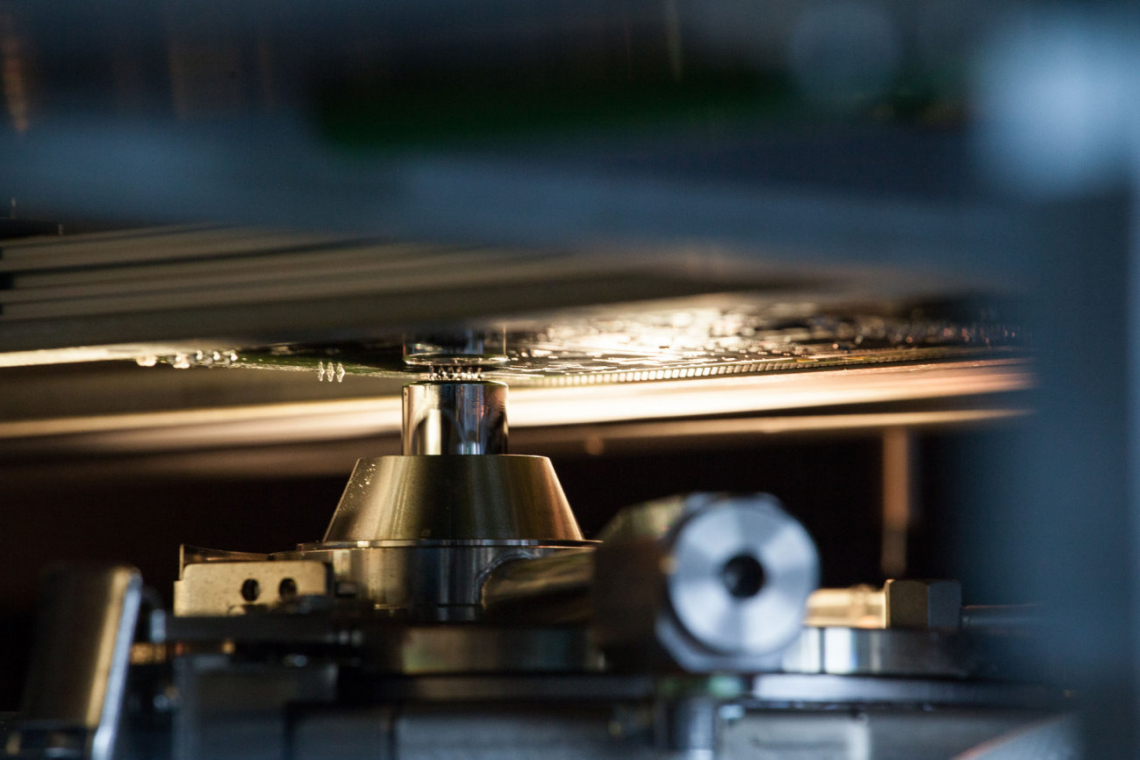

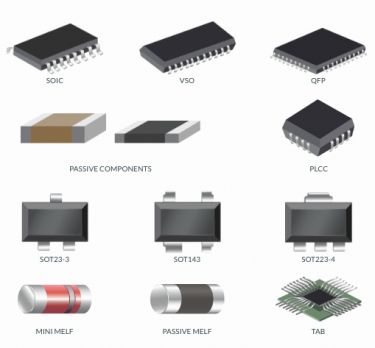

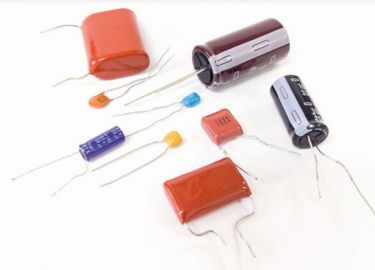

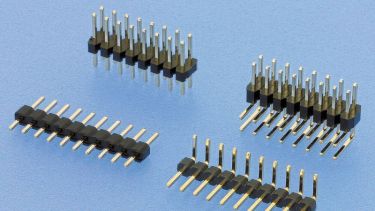

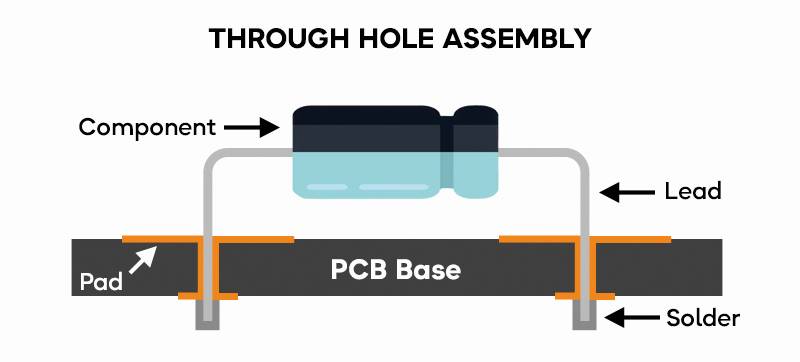

THT, also known as through-hole technology or pin-in-hole technology (PIH), refers to an assembly method in assembly and connection technology in which the connecting wires or pins of the electronic components are inserted through contact holes in the PCB and then connected to the conductor track using soldering (conventional hand soldering, wave soldering, selective soldering). There are both active and passive THT components with radial and axial connections(Fig. 1, 3). There are also electromechanical components. In 2025, THT components will mainly be used for special applications, e.g. large capacitors, coils, connectors, switches or components with high mechanical loads and performance requirements.

Fig. 1: Symbolic representation of THT assembly on a printed circuit board

Fig. 1: Symbolic representation of THT assembly on a printed circuit board

SMT, or surface-mounted technology, refers to an assembly method by which SMD components (surface-mounted devices), in contrast to THT components with their solderable connection surfaces or legs, are placed directly on the contact pads of a PCB in the solder paste and usually reflow-soldered(Fig. 2).

That leaves THR. In the age of SMD assembly using highly productive automatic placement machines and automated soldering processes, it made sense to make connectors, for example, which were not actually suitable for the high temperatures of SMT processing, accessible to the reflow soldering process. Through-hole reflow technology (THR) was developed for this purpose. The material and design of THT components are developed in such a way that they are suitable for automatic assembly and the high thermal load in the reflow oven. This reduces the costs for automatic PCB assembly, as some of the process steps involved in normal THT assembly are no longer necessary(Fig. 4). The terms PiP - 'Pin in Paste' and PIHIR - 'Pin in Hole Intrusive Reflow' are also used for THR technology.

Historical chronology

The chronological sequence of the appearance of the three assembly processes reflects the forward development of the electronics industry in general and, in particular, the advancing rationalization of component and device production and the necessary design changes to components. From the 1960s onwards, the demand for electronic products for civilian use increased rapidly, for example for televisions and radios. This required more effective and faster production, combined with greater material economy. This led to a massive transition to the use of printed circuit boards.

Although the printed circuit board itself was invented in 1936 by the Austrian engineer Paul Eisler, it was not yet widely used. However, it was the decisive basis for the later transition to THT assembly of components. From the 1950s, PCB assembly using THT technology began to establish itself in isolated cases, but it was not until the mid-1960s that the wires of the electronic components of an electrical circuit, which had previously mostly been soldered individually to soldering posts, were mounted and soldered together on a PCB with holes and conductor tracks. Ironists at the time liked to talk about the replacement of the 'wire house' that had prevailed until then. As a 16-year-old vacation worker at the Neustadt-Glewe radio factory in 1961, the author of this article 'fabricated' such products by hand soldering together with many women on the assembly line.

In the 1970s, the first experiments with surface-mount components began in the form of Japanese MELF technology (Metal Electrode Leadless Face). The cylindrical MELF components (see Fig. 2 below) were the pioneers of today's SMD technology. In particular, the passive components predominant in the electronic circuits of the time, such as resistors, capacitors and diodes, were converted into the MELF form and placed on the PCB with astonishing productivity by the Japanese electronics manufacturers in the first automatic placement devices. The aim was to advance the efforts of producers of electronic consumer goods towards highly effective automated assembly of PCBs. MELF technology laid the foundations for today's SMT assembly technology.

THR technology for the assembly of connectors using reflow soldering was not introduced and established in electronics production until the 2000s. To this day, it is a special solution that comes in third place after SMT and THT in terms of the proportion of connectors in electronic devices, for example.

To summarize: The period from the beginning of the widespread active use of THT technology to the widespread introduction of SMD components and the greater use of THR therefore spanned 45-50 years.

THT-SMT ratio

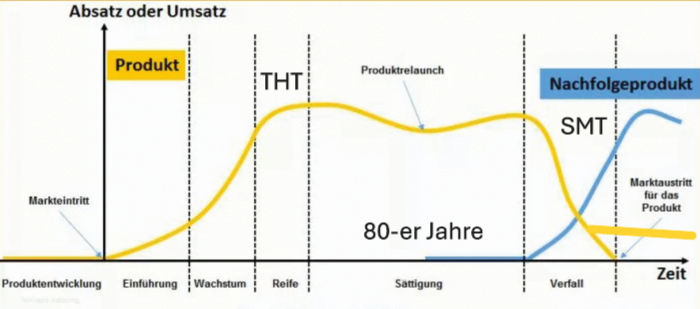

The global production of components suitable for the three assembly processes THT, SMT and THR correlates with the course of the introduction and use of the three assembly processes. In business administration, the concept of the product life cycle includes the five phases of the cycle: introduction, growth, maturity, saturation and decay(Fig. 5). Although they generally apply to specific products, they can also be used to a limited extent for technologies.

The use of THT (through-hole technology) components in electronics reached its peak in the 1980s, when SMD technology was still in its infancy. Until the end of the 1980s, THT technology was the standard method for assembling printed circuit boards, as there were practically only THT components available at that time and the component basis for SMT was not yet sufficiently developed. The 1990s saw the rapid rise of SMD technology because it allowed a significantly higher packing density of components on the boards and thus a higher degree of miniaturization of the assemblies. The automation of the production process also took on a new quality. This was complemented by a significant increase in material economy in the production of SMD components.

As a result, the proportion of THT components in the total quantity of components used in the global electronics industry began to fall significantly in the early 2000s, as the vast majority of components were already available in SMD versions.

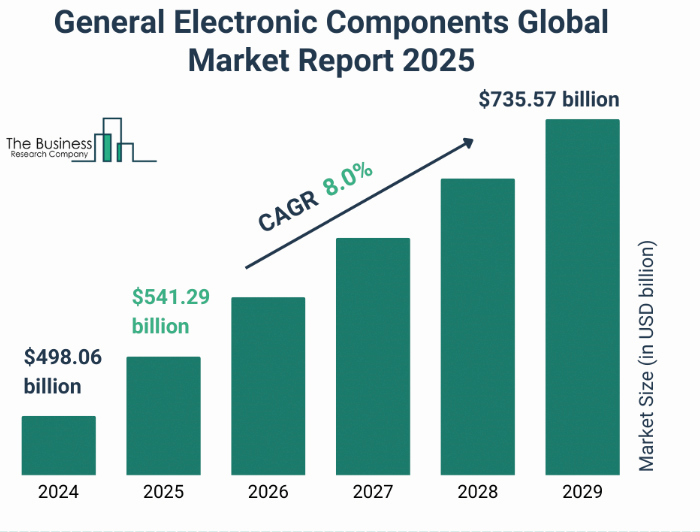

Are plug-in components now in the obsolescence phase according to Figure 5? The answer to this question is not that simple, because the fact that electronification is rapidly penetrating more and more areas of humanity means that the absolute demand for components is also increasing. This is illustrated in Figure 6, which shows the development of global component production from 2024 to 2029, published by The Business Research Company. It states: The market for general electronic components is expected to grow strongly in the coming years. It will grow in value from $498.06 billion to $735.57 billion by 2029 at a compound annual growth rate (CAGR) of 8.0% [1]. Of course, the value share of THT components is included in this forecast, the only question is how large.

Fig. 5: Five phases of the product life cycle

Fig. 5: Five phases of the product life cycle

Exact percentages for the quantity ratio of SMD-THT components are hard to come by. They are not mentioned in current sources. However, general statements from some international publications can be used as an indirect aid. Various sources state that the SMD share in industrial production is typically over 90%, while the THT share is below 10%. Other sources even state for 2025 that around 90-95% of all components used in electronics production will be SMD components, but that there are still technical limits to completely replacing THT components. This is partly due to special requirements for electronics that cannot yet be satisfactorily met by SMD components.

To get a certain impression of how high the value share of THT components could have been in the total global sales of components in 2024, we simply transfer the above-mentioned shares of THT components in the total number of components to the figures shown in Figure 6. This means that a hypothetical share of 10% would be around $50 billion, $74 billion in 2029 and only $25 billion and $37 billion respectively for a 5% share. The author is aware that this is an extremely simplified approach. However, the decisive factor here is not whether the figures are correct or not (they always differ significantly between the individual market research companies), but the statement that THT components are also likely to experience a significant increase in production in the period 2024-2029. It is therefore understandable that experts are talking about a THT revival.

In Figure 5, this is indicated by the thick yellow line on the right of the image, which will run parallel to the x-axis for either a few or even many years (or possibly decades) to come. At best, the thick yellow line may even rise slightly. The classic product life cycle of business administration does not apply here, as there are primarily technical factors that have a decisive influence on the 'expiry time' of THT as a basic technology for electronics production.

Fig. 6: Development of global component production from 2024 to 2029. The US figures in $ trillion correspond to $ billion in Europe

Fig. 6: Development of global component production from 2024 to 2029. The US figures in $ trillion correspond to $ billion in Europe

Advantages and disadvantages of THT

There is a consensus in the international literature that THT plays a critical role in improving the reliability and performance of many electronic systems. For applications that require robust and reliable systems, robust THT components and assemblies or devices based on them are also essential.

In [2] general advantages for THT are mentioned:

Mechanical durability

THT components are securely soldered to the PCB, making them resistant to damage and ensuring long-term reliability

Higher electrical load capacity

THT components can handle higher voltage and current levels than their SMD counterparts due to their often larger dimensions. They are therefore also particularly suitable for high-performance applications due to their robust connections

Easier handling and assembly

Because common THT components such as resistors, capacitors, diodes, transistors and ICs are generally larger than the corresponding SMT components, they are easier to handle and solder manually

Simple replacement

When THT components fail or require upgrades, they are easier to replace due to their safe solderability and size, facilitating maintenance and repair processes

Strong mechanical connection

THT components provide a robust mechanical connection to the PCB, making them more suitable for applications with high mechanical stress or vibrations

Thermal resilience

THT components have better heat dissipation due to larger dimensions and efficient thermal coupling with the carrier. Disadvantages according to [2].

Space consumption

THT components take up more space on the board, which can be a challenge for compact or densely populated designs and imposes significant limitations on the designer. THT is less suitable for HDI boards due to the larger dimensions of the components, which require more space and can consequently lead to increased costs

Limited availability

With the trend towards SMT, specialized THT components may only be a secondary option due to limited availability, which may limit design flexibility

Parasitic effects

The longer connections of THT components may introduce parasitic effects of an inductive or capacitive nature, limiting the maximum achievable frequency or signal speed in high-speed applications

Mechanical stress

THT components with greater weight placed closer together in high density designs can lead to exacerbated mechanical stress in PCBs, which can lead to failures in the traces over time. This emphasizes the importance of careful design considerations to ensure long-term reliability

Cost

THT can lead to higher costs in assembly production compared to hypothetical SMD solutions, not least because the cost of THT components is often higher and the effort required to process them is greater

Higher material consumption

Fig. 7: CERDIP components are well suited to harsh operating conditionsFigures 1 and 3 clearly show that many passive THT components lead to higher metal consumption, e.g. due to their long connecting wires, and that waste is generated after component preparation (trimming). From the point of view of resource conservation (and therefore from an environmental perspective), this is a significant negative factor for THT, which has an unfavorable impact on its future

Fig. 7: CERDIP components are well suited to harsh operating conditionsFigures 1 and 3 clearly show that many passive THT components lead to higher metal consumption, e.g. due to their long connecting wires, and that waste is generated after component preparation (trimming). From the point of view of resource conservation (and therefore from an environmental perspective), this is a significant negative factor for THT, which has an unfavorable impact on its future

As a transitional or compromise solution, hybrid approaches are still often pursued today to optimize performance and costs: Many PCBs combine THT and SMT. Hybrid assemblies offer the flexibility and reliability of through-hole technology combined with the efficiency and compactness of SMD technology.

Applications of through-hole technology

THT is preferred for applications that require greater mechanical robustness and/or high thermal load capacity. As they are better suited to manual assembly than SMD, they are also used for prototyping and small series production.

The advantages of many THT components for harsh operating conditions can be clearly demonstrated using the example of Ceramic Dual In-line Packages (CERDIP)(Fig. 7). The hermetically sealed DIP components can withstand temperatures of up to 150 °C and a humidity of 85 % and comply with the MIL-STD-883 standard. Their robust design offers excellent vibration and thermal shock resistance, making them ideal for demanding applications such as automotive ECUs and aerospace electronics. Table 1 lists areas of application in which THT is used [2].

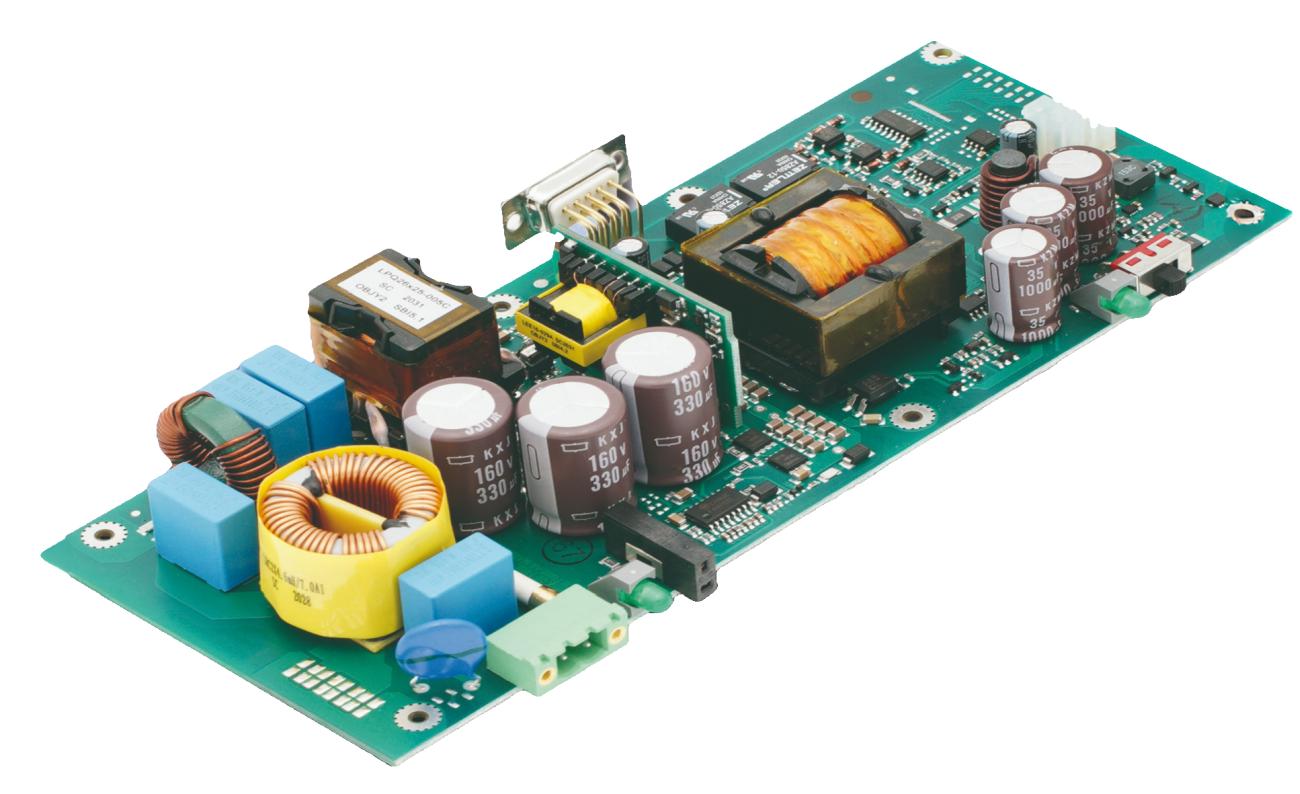

An illustrative and typical example of the use of THT is the latest PSU-0262-10 switched-mode power supply from inpotron Schaltnetzteile. It was developed according to customer specifications for communication technology and is realized in hybrid design - THT and SMT technology(Fig. 8).

Fig. 8: PSU- 0262-10 switched-mode power supply from inpotron Schaltnetzteile

Fig. 8: PSU- 0262-10 switched-mode power supply from inpotron Schaltnetzteile

Prospects

Most of the technology areas listed in Table 1 are classified by market analysts as 'future markets'. This means that they will not be shrinking markets, but prospering ones. For example, the market size for medical devices is estimated at $637 billion in 2024 according to [4] and is expected to reach around $893 billion by 2029, which corresponds to an average annual growth rate of 6.99% over the forecast period. It can be assumed that THT technology will also benefit from this growth, even if some of the existing THT solutions in medical equipment will have to accept losses due to more SMD use.

As we look to the future of electronics assembly, it is exciting to imagine how new components, techniques and innovations will also shape the landscape of through-hole technology. Despite the growing popularity of SMT technology, through-hole technology continues to hold its own by fulfilling a wide range of applications and industry requirements.

When deciding between through-hole and SMT for a project, it's not just about weighing up the pros and cons. It's also about understanding the nuances of your specific application and finding the alignment for both options. Factors such as cost and assembly efficiency as well as reliability must also be considered.

| Technology area | Application examples |

| Automotive industry | Vehicle control, engine management and infotainment systems |

| Aerospace industry | Avionics, navigation systems and communication devices |

| Industrial machinery | Industrial automation and control devices, e.g. PLCs, motor drives and power supply units |

| Medical products | Patient monitoring devices, diagnostic instruments, surgical instruments |

| Telecommunications | Telecommunication devices, e.g. infrastructure components such as switches, routers and base stations |

| Consumer electronics | Audio amplifiers, power supply units, connection components |

| Instrumentation and measuring devices | Oscilloscopes, multimeters, data loggers |

References

[1] www.thebusinessresearchcompany.com/report/general-electronic-components-global-market-report (accessed: 24.6.2025).

[2] www.srmtech.com/knowledge-base/blogs/what-is-through-hole-technology-a-comprehensive-overview/#introduction-to-through-hole-technology (Retrieved: 24.6.2025).

[3] https://hilelectronic.com/de/smd-components-dip-components/ (Retrieved: 25.6.2025).

[4] www.mordorintelligence.com/de/industry-reports/global-medical-device-technologies-market-industry (Retrieved: 25.6.2025).