A great deal of theoretical knowledge is available for industrial cleaning processes and quality assurance in component manufacturing. Now it is also possible to train the mastery of complex process chains in component cleaning in the new learning laboratory for industrial parts cleaning, the LinTR.

Supported by the Fraunhofer Academy, the Fraunhofer IPA, the Fraunhofer IVV Dresden and the Fraunhofer IWS are working under the direction of the Fraunhofer FEP to design and implement the expanded training opportunities. The training concept has a modular structure. Depending on the requirements of the participants, a three-day compact seminar is offered, for example, or an in-service qualification. Laboratories at all four project partners are available for practical skills training, including a laser laboratory at the Fraunhofer Institute for Material and Beam Technology IWS in Dresden. The Fraunhofer Institute for Manufacturing Engineering and Automation IPA in Stuttgart offers special laboratories on the topics of cleanrooms and particle cleanliness. The simulation and practical implementation of spray cleaning are available in the laboratories of the Fraunhofer IVV Dresden, among others.

Standardized starting conditions

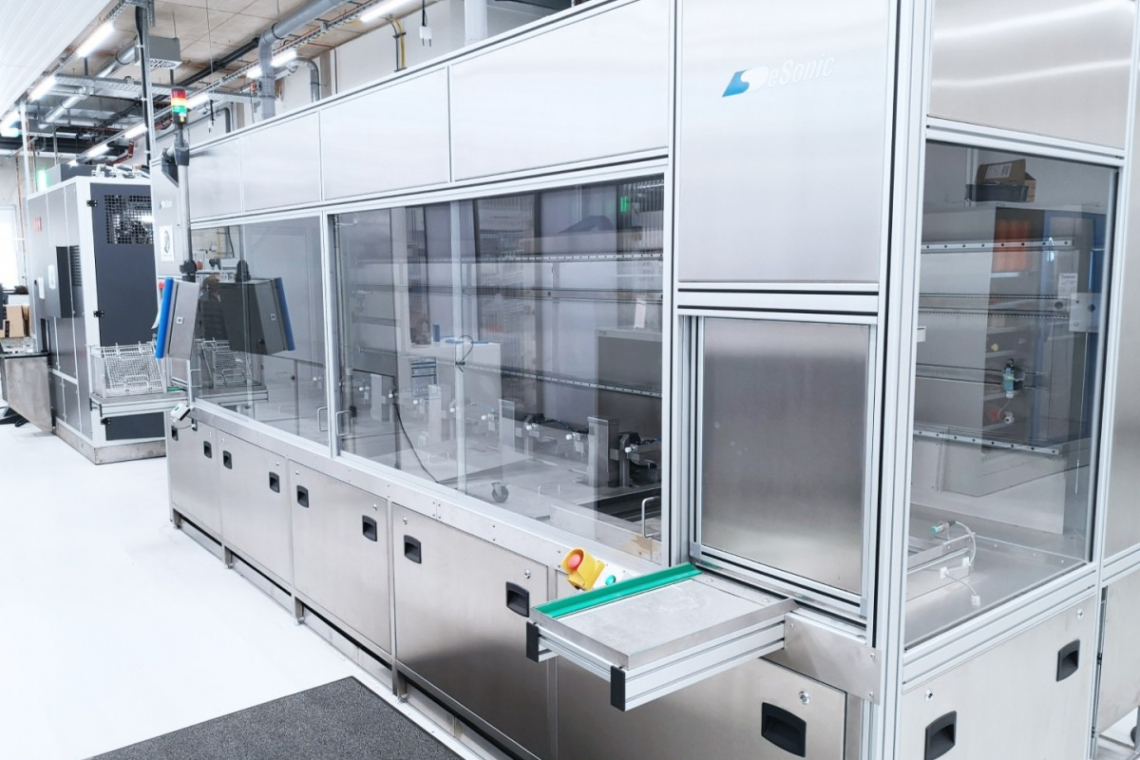

As part of the project, the existing cleaning technology at the Fraunhofer FEP was expanded to include a multi-chamber cleaning system for aqueous ultrasonic cleaning. The system has a capacity of 100 liters per tank. The system enables the control of individual ultrasonic generators. This allows the direction, frequency and power of the ultrasound and therefore the cleaning effect to be varied. The sequence of cleaning processes in the six tanks can also be freely adjusted via an automatic system. Various cleaning processes and test methods are used in practice. A special two-part test component was developed for this purpose, which contains typical geometries and materials of industrial components, such as various drill holes, edges and screw connections as well as material combinations of metal, plastic and additively manufactured components. The training participants optimize the cleaning parameters for these standard components in the multi-chamber system. The standard component is contaminated with typical production-relevant substances (lubricating oil, cooling lubricants and grinding pastes) in a standardized manner and then processed using various methods. The standardized initial conditions enable a comparative analysis of the various processes and show the limits and possibilities of the methods using a practical example. The multi-chamber cleaning system should be available for the first practical cleaning processes by the end of the year.