Generations of literature professors have analyzed and commented on this witchcraft 101. Even the good Eckermann, who intentionally or unintentionally dismantled Goethe with great care, left a comment[2] on this subject by the beloved Johann Wolfgang himself. In some ways, the process engineers who singulate panels have it easier. Although they can choose from a range of methods, no Goethe specialist is going to mess with them about it.

In many productions, large PCBs consisting of a number of individual products are sent together through the various machines to be finally disassembled. This approach has a number of advantages as well as a few difficulties to overcome. To facilitate disassembly, the break points are usually scored or partially milled, and only a few bridges are left for cohesion - a particular art to get right, as this clearly makes the large PCB far more unstable, especially if it is only held sideways and runs through heat processes.

The final problem is how to detach the individual smaller PCBs without damaging them.

If the PCBs are not assembled, the procedure is much simpler than with fully assembled and already soldered PCBs. Here, components are often located directly next to the cut edges, possibly even in an unfavorable orientation or with particularly high component bodies, so that there are few methods that can reliably accomplish this.

What methods are available, depending on whether scribing or milling was carried out beforehand?

Breaking out by hand

This is probably the method most often encountered in smaller productions. It is carried out in a wide variety of ways, from breaking with special tools for printed circuit boards to cracking on the edge of the table or over the knee.

As long as the assembly can withstand such treatment, there is actually nothing wrong with it. However, components and solder joints are often broken and therefore damaged.

The main disadvantage is, of course, that every person makes major or minor deviations from the desired method with every handling - often unintentionally. There are the places where he or she grips, the speed at which the breakage occurs, etc. etc.

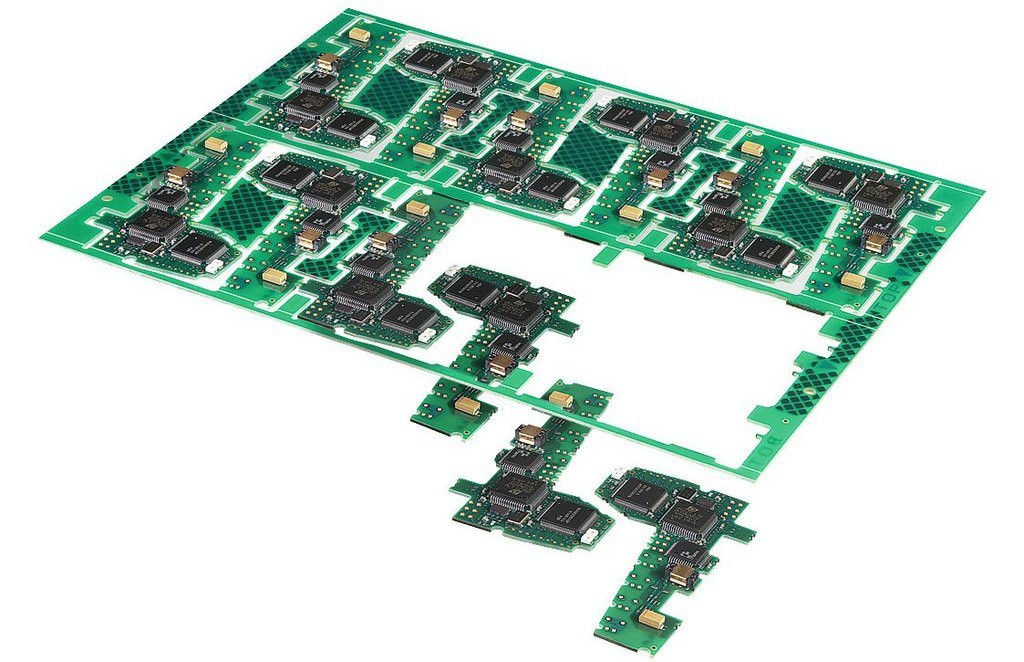

Panel, which is made up of several assembled circuit boards

Panel, which is made up of several assembled circuit boards

Cutting with a so-called 'pizza cutter'

This somewhat ingloriously named machine is widely used because it comes quite cheaply and is easy to maintain: oiling and sharpening the cutting surface is practically all that is required. Pre-scored panels are usually cut - and in a straight line. No problem as long as the assembly has been properly designed - arrangement of sensitive components far away from the cutting edge, correct orientation, distance from the cut - because a small stress wave runs in front of the round disk, which can represent a load up to a few mm away.

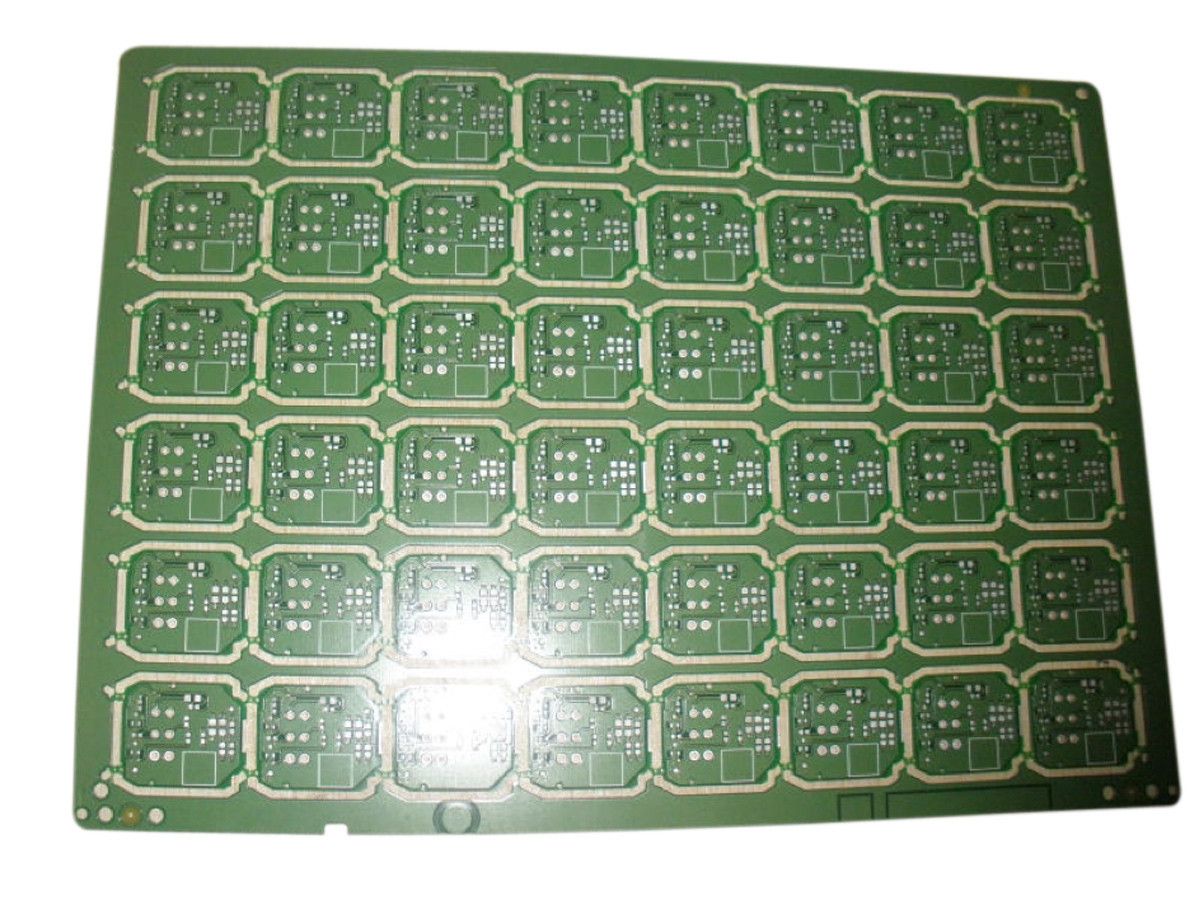

Panel with 48 unpopulated individual circuit boards; image: Dongguan Chuangwei Electronic Equipment Manufactory

Panel with 48 unpopulated individual circuit boards; image: Dongguan Chuangwei Electronic Equipment Manufactory

Nibbling out the bars with a 'nibbler'

Companies often have this done with pliers or special tools, but there are also small devices that can be used. If done correctly, the edges do not need to be smoothed any further. Depending on how the PCB is held, there is less stress than with some of the other methods, especially if the ridges are removed one at a time.

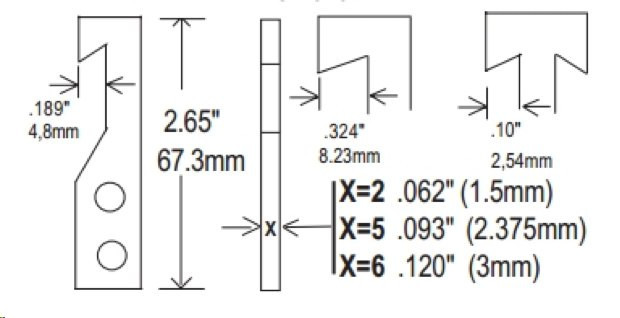

Different cutting blades of a 'nibbler'

Different cutting blades of a 'nibbler'

Cutting out with a punch

This is probably a further development of 'nibbling', which is well known in many other industries (metal, wood, plastic ...). Because many of the parts can be removed at the same time, the throughput is high, but the tools are expensive and complex to maintain (complicated sharpening).

Saws

Diamond saws are usually used because they produce a smoother cut and need to be replaced less frequently. Cuts are straight, but also very narrow, so that far less dust is generated than with milling. The mechanical load on the assembly is also lower.

Milling

Printed circuit board, consisting of four identical sub-boards, before depanelingFamiliarto DIY enthusiasts, the router for printed circuit boards differs only slightly from the device used in the woodworking industry. Usually, but not always, only webs are removed. The router head is selected accordingly and the feed rate is adjusted in conjunction with the rotation speed of the head. Milling generates a lot of dust and transmits vibrations, so their effects on components should be checked and the circuit board must be held well, which is important if curves or sudden changes of direction are also being made.

Printed circuit board, consisting of four identical sub-boards, before depanelingFamiliarto DIY enthusiasts, the router for printed circuit boards differs only slightly from the device used in the woodworking industry. Usually, but not always, only webs are removed. The router head is selected accordingly and the feed rate is adjusted in conjunction with the rotation speed of the head. Milling generates a lot of dust and transmits vibrations, so their effects on components should be checked and the circuit board must be held well, which is important if curves or sudden changes of direction are also being made.

Cutting with the laser

Instead ofCO2 lasers, UV lasers with a wavelength in the ultraviolet range (355 nm) are used today. They can also be used to cut flexible PCB foils and normal foils up to a thickness of around 1 mm. About 25 µm of material is removed very precisely (± 4 µm). The beam can vaporize just about anything the PCB industry can throw at it:

- FR4 and similar resin systems

- polyimides

- ceramics

- PTFE and PET

- aluminum

- And even copper and some other metals.

As a cutting method, it is certainly one of the most expensive, but also one that puts little strain on the assembly and can negotiate the boldest curves.

The router for printed circuit boards is hardly any different from devices used in the woodworking industry, as DIY enthusiasts are well aware.

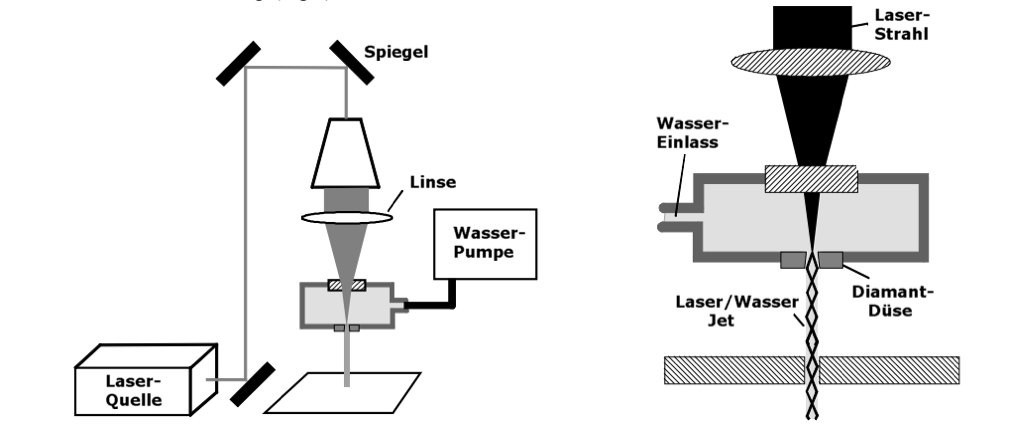

Water jet guided laser

This new technology, which has been known for some time in the aerospace industry, still needs to be further developed for the PCB industry.

Once again, it seems that the more efficient, faster and safer the process is, the more expensive it will be.

We have already indirectly addressed a few considerations regarding a choice. Here is a somewhat longer list, which does not claim to be exhaustive:

- How are the panels designed?

- How sensitive is the product?

- How many panels need to be singulated per hour, for example?

- How much can it cost?

- What space is available?

- To what extent should the process be automated?

- How well trained are the workers?

- How many shifts are required?

- How flexible should the singulating be?

- Are only straight lines involved or also curves?

- Is documentation required?

- Which PCB material is used?

- How thick is the PCB?

- How large is the largest panel?

- Are there any overhanging components such as connectors?

- ESD effects?

Laser-guided water jet; Image: Dept. of Atomic Physics, Budapest Univ. of Techn. and Economics

Laser-guided water jet; Image: Dept. of Atomic Physics, Budapest Univ. of Techn. and Economics

References

[1] The witch's painting from Goethe's 'Faust I' in the scene 'Hexenküche'.

[2] "But there are not a few passages in his book where the thought does not move and progress and where the dark language always moves on the same spot and always in the same circle, completely like the witch's multiplication table in my Faust." - Johann Peter Eckermann: Conversations with Goethe in the last years of his life, vol. 3, 1848.