Healing, healing geese

It will soon be good again,

The kitten has a tail

It will soon be well again,

All is well with the mouse

In a hundred years it will all be gone. [1]

Intel co-founder Gordon Earle Moore, famous for his Moore's LawWartscan be successfully 'discussed', especially with children and some gullible adults. Apparently, the above saying also alleviated the pain of minor aches and pains when the mother sang it to the suffering child. Ernst Neger also used this during his performance at the Fassenacht, probably mindful of the hangover that some of the participants had to suffer the next morning. As with the youth, this singsong became very popular with the fools.

Intel co-founder Gordon Earle Moore, famous for his Moore's LawWartscan be successfully 'discussed', especially with children and some gullible adults. Apparently, the above saying also alleviated the pain of minor aches and pains when the mother sang it to the suffering child. Ernst Neger also used this during his performance at the Fassenacht, probably mindful of the hangover that some of the participants had to suffer the next morning. As with the youth, this singsong became very popular with the fools.

Whether a hundred years is long enough is debatable, given the increasing longevity of electronic products. However, electronic products usually only last a few months or years, either because they were designed that way or because the sensitivity and rough handling of these often 'unrepairable' products means they end up as hazardous waste or are stowed away in a drawer as a souvenir.

The complexity of both components and assemblies has increased dramatically. Not only does Moore's law [2] apply, but the smaller passive components mean that the distances between them have to be reduced, which in turn leads to a reduction in current levels and voltages.

The 'spitball' [3] of RoHS has made soldering more complicated, greatly increased energy consumption and raised the problem of flux to a new level. Whereas in the good old days you could simply leave the resin on the assembly - old telephones from manufacturers' showcases still work even though the resin inside is already flaking off - contamination is now hardly acceptable if you want to give the product a longer service life.

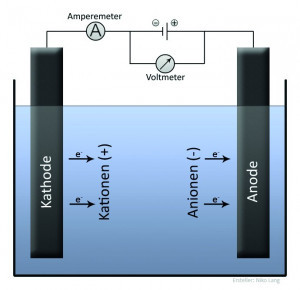

Electrolysis, illustration by Niko LangThisoften depends on a phenomenon that is well known from physics and chemistry: electrolysis. This involves the voltage series, an electrolyte and you are potentially faced with a problem. The dendrites that grow there are something else than the so-called 'whiskers', which are pressed out of metal layers.

Electrolysis, illustration by Niko LangThisoften depends on a phenomenon that is well known from physics and chemistry: electrolysis. This involves the voltage series, an electrolyte and you are potentially faced with a problem. The dendrites that grow there are something else than the so-called 'whiskers', which are pressed out of metal layers.

Ion migration is the culprit here and this involves a few participants. The metals and an electrolyte are important. If a conductive connection between different metals is made possible, metal ions migrate from one side to the other and accumulate in pretty-looking metal crystals that are not unlike Christmas trees. Unfortunately, however, this leads to short circuits. The closer the distance, the faster the connection can form.

But what can be done about it? Different metals are fundamentally necessary for the function. Avoiding them belongs to the realm of fantasy in electronics.

So the focus is on the electrolyte. How is it formed, because it is not supplied with the device - or is it? It is formed from certain impurities and the ever-present humidity.

This is where suspicion (not always justified) falls on the flux. An 'ideal' flux removes the oxides during soldering (and fulfills several other functions) and then disappears without a trace. However, especially after RoHS, chemists have not yet succeeded in doing this.

Although it is possible to solder without flux, this is too time-consuming and therefore too expensive, especially in mass production. So you just fiddle around with chemicals and residues remain that rise to the electrolyte under the expected conditions.

However, it should not be overlooked that impurities can also be introduced in other ways. PCB production uses a number of chemicals. So do the component manufacturers. Whether they are all removed or can be removed remains to be seen. Handling, packaging and machines are also not innocent in the situation.

The exclusion of humidity is used in some vacuum-packed components. If they are completely dry, electrolyte cannot form and waft around. It would be conceivable to translate this to the assembly as a whole, but it is unrealistic.

SpectrometerSoit's all about the impurities. Washing assemblies has given RoHS a new lease of life. After attempts were made to largely prevent cleaning with low-solids fluxes - also for cost and environmental reasons - the high melting temperatures and the tricks now required with fluxes in connection with the general development of components have made washing more popular again.

SpectrometerSoit's all about the impurities. Washing assemblies has given RoHS a new lease of life. After attempts were made to largely prevent cleaning with low-solids fluxes - also for cost and environmental reasons - the high melting temperatures and the tricks now required with fluxes in connection with the general development of components have made washing more popular again.

However, it has not become any easier. Now that freon, which is not particularly effective (which is why it is mostly used as an azeotrope [4]), has been withdrawn from circulation, the search is still on for suitable chemicals. The desired properties are extensive and require above all that the ionizable impurities on the assembly can be dissolved and rinsed off. In addition, there are health and ecological concerns, some of which are also enshrined in law.

The search is made more difficult by the increasingly narrow gaps on the assembly, especially under some of the larger components. Forcing liquid in there is less of a problem than getting it out again with the dissolved impurities.

Since the process engineer has little influence on the design of the assembly, she should at least start her considerations by analyzing the residues that need to be removed.

A proper laboratory can then use the latest analytical methods and local extractions (possibly after removing some problematic components) to definitively indicate what is hiding there.

Since CFC-113 and 1,1,1-trichloroethane are no longer available, one is either looking at some of the newer solvents or speculating with water-based systems that use saponifiers to attack some of the organic residues (resins). In any case, this chemistry needs to be carefully matched to the contaminant, and it is smarter to be convinced by trial and error than to be told the sky is the limit by verbose salesmen.

The normal washing process in continuous or batch systems is excessively long, and new ideas on the machine market seem to be rare. There is now widespread agreement that a little more energy needs to be used to remove the impurities. This is done either with spraying methods or with the previously demonized ultrasound, whereby spraying methods may run into shading problems because components 'obstruct' each other, which is usually cleverly hidden in the publications. Whether the assembly is ultimately clean or at least complies with the limit values set in advance must of course be verified regularly.

Literature

M. Bixenman et al.: Combination of Spray and Soak Improves Cleaning under Bottom Terminations, IPC proceedings

T.M. Forsythe: Cleaning High Reliability Assemblies With Tight Gaps, A Detailed Analysis, SMTA Proceedings

E. Kanegsberg; B. Kanegsberg: Ultrasonics as an Option for Electronics Assembly Cleaning, Proceedings of SMTA International, Sep. 25- 29, 2016, Rosemont, IL, USA

T. Munson: Failure Analysis - Using Ion Chromatography and Ion

Chromatography/Mass Spec (IC/MS), Proceedings of the SMTA Pan Pacific Microelectronics Symposium 2020

R. Basu; R. Hulse: An Alternative Solvent with Low Global Warming Potential, IPC proceedings

H. Conseil et al: Contamination profile of Printed Circuit Board Assemblies in Relation to Soldering Types and Conformal Coating, Proceedings of EuroCorr 2014

References

[1] Rephrasing of a nursery rhyme by Ernst Neger as a carnival song, source: www.wikipedia.org/wiki/Heile,_heile_Gänsje

[2] www.investopedia.com/terms/m/mooreslaw.asp

[3] en.wikipedia.org/wiki/Spitball

[4] en.wikipedia.org/wiki/Azeotrope