We all do our best. It would be wonderful if our products still worked reliably decades later. But in everyday life, we observe that even simple devices in 2025 often give up the ghost faster than you can say 'extended warranty'.

Home computers from the 1980s often still work perfectly today - while an electric shaver from just three years ago suddenly breaks down. This phenomenon, known as planned obsolescence, raises questions about ethics, sustainability and technical feasibility - especially in the electronics industry.

Plan or coincidence?

Planned obsolescence refers to the deliberate design of products with a shortened lifespan. Various methods are used here, involving both physical and software-based elements. The decisive factor is the deliberate choice of materials, component architectures and design principles that induce premature decay.

Planned obsolescence was even considered a 'conspiracy theory' at times, but it is now fairly well documented [1]. However, not all damage was planned in advance and it is not always easy to accuse the industry of intent. Sometimes it is simply a case of sloppiness or cutting corners. Proof requires at least one clearly recognizable pattern, the result of which shows that the customer was harmed and the manufacturer profited at the same time. This is not always easy, which is why an even better way is through whistleblowers.

A brief history of planned obsolescence

Some cases of planned obsolescence are now well known. For example, the incandescent light bulb, which lasted around 3000 hours in 1924 but only reached 750 hours in 2009 [2]. The situation is similar with non-replaceable batteries, for example in smartphones and electric toothbrushes [3]. Here, the expiry date is practically built in. Gear wheels and other crucial mechanical parts are made of plastic instead of metal so that they reliably fail after a number of predetermined cycles or loads.

Many printer cartridges are equipped with a chip that prevents them from being refilled indefinitely. It is one of the most expensive liquids in the world - behind scorpion and snake venom, LSD, arrow-tailed crayfish blood, Chanel No. 5, insulin and mercury. Updates are supposed to fix bugs and optimize systems, but we often find the opposite to be true. Whether it's the operating system or drivers, the feeling that things are running worse after the update than before is no coincidence. The hardware requirements of the operating system with the window symbol have suddenly increased, the graphics card is performing less well in your favorite game since the last driver update. Sometimes these are bugs that will be fixed with an upcoming patch, but the frequency makes it hard to believe that this is a coincidence.

Many printer cartridges are equipped with a chip that prevents them from being refilled indefinitely. It is one of the most expensive liquids in the world - behind scorpion and snake venom, LSD, arrow-tailed crayfish blood, Chanel No. 5, insulin and mercury. Updates are supposed to fix bugs and optimize systems, but we often find the opposite to be true. Whether it's the operating system or drivers, the feeling that things are running worse after the update than before is no coincidence. The hardware requirements of the operating system with the window symbol have suddenly increased, the graphics card is performing less well in your favorite game since the last driver update. Sometimes these are bugs that will be fixed with an upcoming patch, but the frequency makes it hard to believe that this is a coincidence.

A recent case is Windows 10, which according to Microsoft should be the 'last version' [4]. We have had Windows 11 since 2021, support for Windows 10 will be discontinued on October 14, 2025 and millions of perfectly functioning desktop PCs will have to switch operating systems for security reasons. But the plan only worked to a limited extent: Wherever possible, numerous users are switching - albeit to Linux.

There are many more examples. Apple and Samsung were fined millions in 2018 because their operating system updates slowed down older devices, forcing users to buy new ones [5]. Ink cartridges are equipped with chips that make printing impossible as soon as the fill level falls below a certain limit, even though there is still ink left [6]. Some chips can stop printing when certain levels are reached, especially in refill printer cartridges [7]. Some manufacturers use chips or software to block use after a certain number of prints. Firmware updates from printer manufacturers can specifically exclude compatible chips or refilled cartridges, which can block usage [8]. Such updates cannot always be avoided. The case is harmless if the software is annoying with corresponding messages. Occasionally, the hardware also takes care of itself if it is connected to the network and has access to the internet.

Windows 10 at a presentation in 2015 - advertised at the time as the 'last Windows version' ever

Windows 10 at a presentation in 2015 - advertised at the time as the 'last Windows version' ever

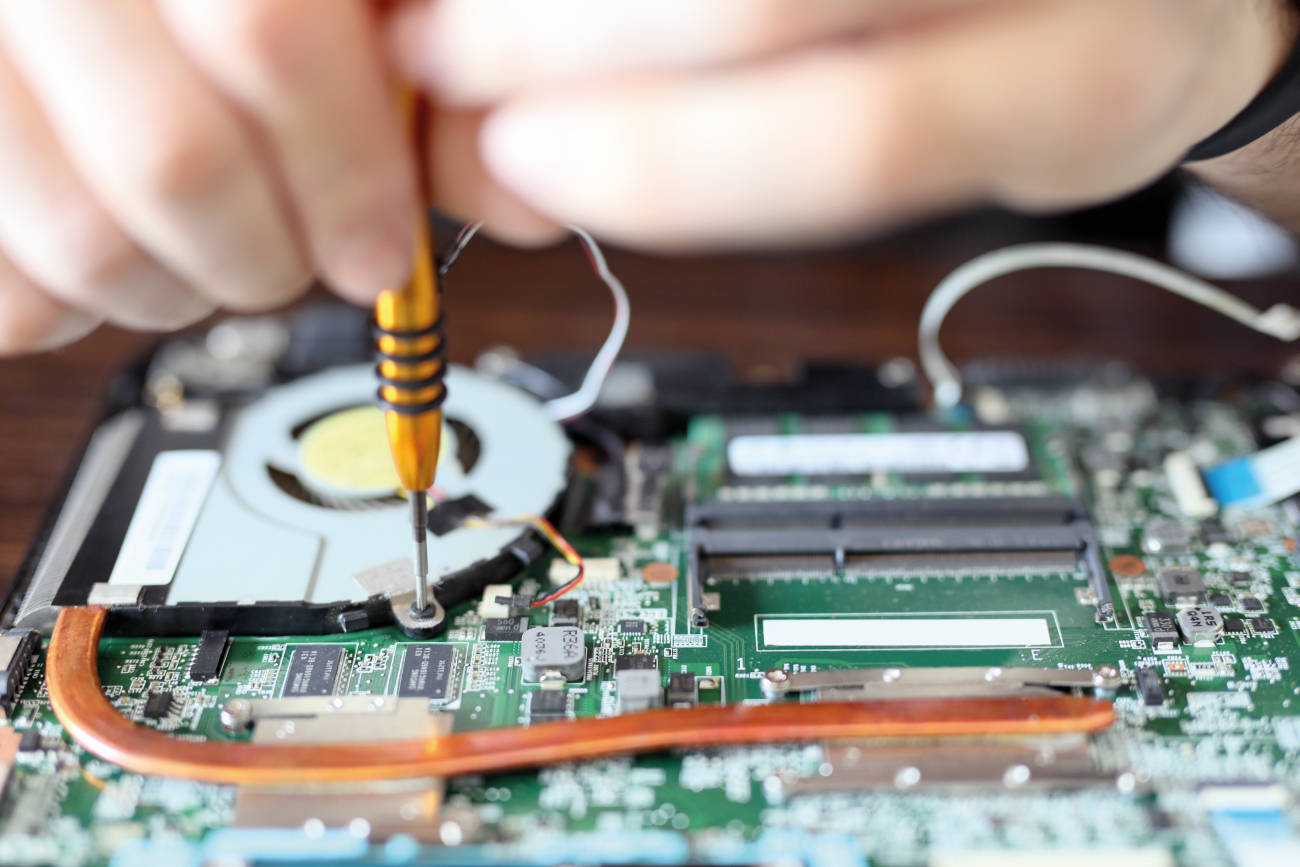

The case of printed circuit boards

Circuit boards are sometimes deliberately designed with features that shorten their service life. A frequently observed phenomenon is the placement of critical solder joints in areas where mechanical stresses are particularly high. For example, the power supply connection is integrated in such a way that every time the power cable is plugged in, considerable leverage is exerted on a few soldered connections. The combination of a tight installation space, suboptimal mechanical designs and the use of brittle soldering materials leads to accelerated mechanical fatigue of these connections. A detailed investigation of such design decisions shows that the deliberate shortening of the service life of connections - for example at the edges of a circuit board - significantly increases the risk of complete failure after just a few years [9].

Tin whiskers (tin dendrites) in a guitar amplifierOtherexamples, although not always planned, are as follows:

Tin whiskers (tin dendrites) in a guitar amplifierOtherexamples, although not always planned, are as follows:

- Manufacturers use weak soldering materials or error-prone soldering processes to make connections susceptible to cracking or overheating (e.g. in graphics cards, smartphone PCBs)

- Tin whiskers that cause short circuits due to cheap solder

- Components are placed on circuit boards in such a way that repairs are impossible or uneconomical

- Integration of software locks that deactivate devices after hardware repairs (e.g. Apple's 'Error 53' when replacing displays) [10]

- Overheating of critical components due to poor cooling or placement close to heat sources to weaken solder joints (often with low-cost manufacturers)

- Manufacturers deliberately choose capacitors with a lower temperature tolerance (e.g. 85 °C instead of 105 °C) to save costs - at the expense of durability

However, this is often not intentional, but a combination of technical difficulties and cost pressure. This is shown, for example, by the 'Annual Outage Analysis 2022' [11]. Around one in five companies had a serious outage in the previous three years, with costs rising significantly. Over 60% of outages cause damage of at least $100,000, and the proportion of outages costing over $1 million has also risen. Despite high investments and improved technologies, digital infrastructure operators have not yet succeeded in significantly reducing failure rates. To counteract the rising costs, risks and disruptions, an increased focus on training and optimized operational processes is recommended.

Sustainable perspectives and reflection

The consequences of planned and unplanned obsolescence are far-reaching. In addition to the obvious economic burden on consumers, the frequent replacement of appliances leads to a considerable environmental impact. Electronic waste is a global problem and recycling is often carried out under precarious conditions. This practice also undermines confidence in technological innovation and drives efforts such as 'right-to-repair', which aims to make product development more sustainable and repair-friendly. What is alarming, however, is how much the consumer has been conditioned to the current state - there is hardly any questioning as to why devices that could in principle last for decades should be scrapped after a few years.

Forward-looking approaches in product development should increasingly focus on modular construction methods and durable, repair-friendly designs. These strategies not only help to reduce the environmental impact, but also ensure consumer confidence and interest in the long term. At the same time, the software industry is intensively discussing how support cycles can be extended and the compatibility of older devices can be maintained without restricting the innovative power of new technologies.

In view of these developments, the question inevitably arises as to whether Gottfried Wilhelm Leibniz would describe this situation as "the best of all possible worlds" - or whether it is time to make fundamental changes to the course of technology and product development.

'Right to repair': New EU regulations aim to improve minimum requirements for the repairability of smartphones and tablets

'Right to repair': New EU regulations aim to improve minimum requirements for the repairability of smartphones and tablets

Sources

[1] de.wikipedia.org/wiki/Geplante_Obsoleszenz (accessed: 19.08.2025).

[2] kontrast.at/geplante-obsoleszenz/ (Retrieved: 19.08.2025).

[3] www.all-electronics.de/elektronik-entwicklung/die-grosse-uebersicht-zu-obsoleszenz-die-geplante-alterung-unserer-produkte-58-341.html (Retrieved: 19.08.2025).

[4] en.wikipedia.org/wiki/Microsoft_Windows_10#New_publication_model (Retrieved: 19.08.2025).

[5] www.chip.de/news/Millionenstrafe-fuer-Apple-und-Samsung-Handys-werden-durch-Updates-bewusst-langsamer-gemacht_151383829.html (Retrieved: 19.08.2025).

[6] cartridgecenter.de/chips-on-printer-cartridges/ (Retrieved: 19.08.2025).

[7] www.toner-druckerpatronen.de/info/toner-chip-druckerpatronen-chip.html (Retrieved: 19.08.2025).

[8] www.tonerpreis.de/chips.html (Retrieved: 19.08.2025).

[9] www.krekr.nl/content/ubiquitous-planned-obsolescence-in-consumer-electronics/ (Retrieved: 19.08.2025).

[10] www.notebookcheck.com/Error-53-Apple-blockiert-iPhones-nach-Fremdreparatur.158972.0.html (Retrieved: 19.08.2025).

[11] www.businesswire.com/news/home/20220608005270/de (Retrieved: 19.08.2025).