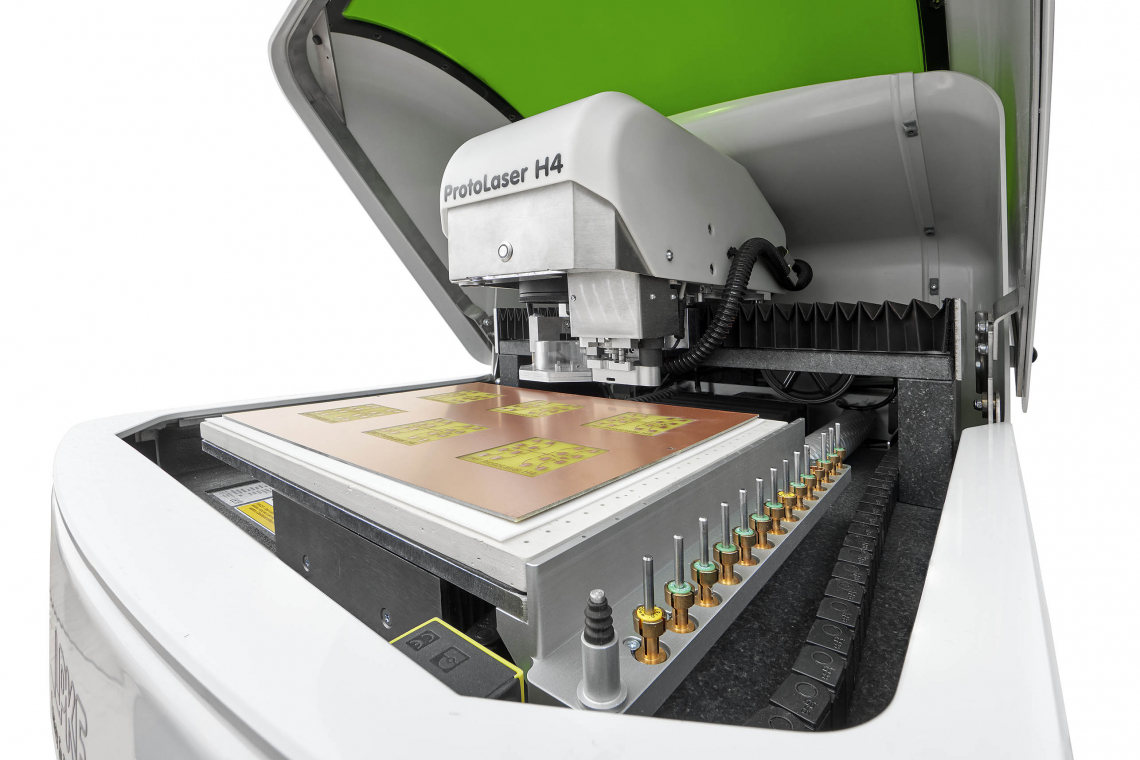

LPKF offers a combination of mechanical processing and laser processing for the chemical-free structuring of PCB prototypes with the ProtoLaser H4. The latest version makes the necessary processes significantly more powerful and efficient.

A higher-rotation spindle, a more powerful laser, the increased number of tool holders, numerous new processing and peripheral features and extended functions of the LPKF CircuitPro system software all contribute to this improved performance. The manufacturer now uses a 20 watt laser in the new version of the ProtoLaser H4 - the previous version had 16 watts. At the same time, the speed has been increased from 60,000 rpm to 100,000 rpm thanks to a more powerful spindle. Thanks to these new performance data, even thick substrates including multilayers with mechanical functions - drilling or cutting - can be structured in combination with extremely fast and precise laser processing. The increased number of tool holders from 6 to 14 significantly supports the user. As a result, a considerable degree of automation can be achieved in this tabletop model, as many consecutive processing steps can be carried out without manual tool changes. This enables, for example, 0.2 mm drill holes, faster cutting of PCBs and also flex materials. The environment around the two processing methods has also improved. Thanks to an optimized suction hood, any material residues are completely removed from the work area.

An integrated MTM device (Material Thickness Measurement) records the height of the material. This improves the focus position for laser structuring in a self-calibrating process. The Z-height increases to 8 mm, so that the working area now grows to 310 mm x 230 mm x 8 mm. The diagonal traversing speed has also been increased once again. A new camera feature can now read in any geometric shape on the PCB as a fiducial. Any processing steps can be created based on this position. These features are available in the extended version of the CircuitPro software. It also includes export to the most important CAD data formats such as Gerber and DXF. The manufacturer from Garbsen near Hanover has been setting standards in electronics production for decades with its LPKF ProtoMats for prototype production of printed circuit boards. "In the spectrum from the smallest system for occasional work to the top model, which also processes sensitive substrates gently at high spindle speeds, the ProtoLaser H4 has already been regarded as the link between mechanical PCB processing and our laser processes," says LPKF Product Manager Eric Scheidler. With the new version of this model, which will be available in September, the combination of mechanical structuring and laser processing should make the prototype production of PCBs much easier and more attractive thanks to the extended possibilities. According to Eric Scheidler, the new version will make it even easier to produce sophisticated prototypes without etching chemistry in the company's own laboratory. However, the range of applications for the system is also to be expanded beyond the prototyping options presented: "The ProtoLaser H4 is also well suited for PCB repair, for example, thanks to the new features."