The 'Future Packaging' line has been part of the event since the first SMT trade fair. Every year, Fraunhofer IZM as the organizer and the participating machine exhibitors aim to demonstrate the current possibilities in the individual processes and technologies. Coordinating the logistics of the various partners with the trades on site in such a way that stress-free production is possible during the trade fair becomes more difficult from year to year: there are always bottlenecks with components or parts for the machines, so that everything has to be planned in detail in advance in order to avoid all imponderables. Right from the start, the focus is on maximizing the knowledge gained by visitors.

In 2024, exhibitors will be asking themselves how far-reaching automation and digitalization can be used to design the individual process steps in such a way that maximum robustness against errors in the processes is achieved. An important aspect for line operators in practice is the entire material flow.

'Smart Material Flow', the autonomous material flow solution from Neotel Technology, for example, offers comprehensive end-to-end management of materials. It covers the individual material flows including material receipt, loading, replenishment, storage and retrieval. For incoming materials, the NeoScan module supports material recognition and UID generation as well as the creation and printing of labels. In addition, internal material transport can be further optimized by the work order planning system and the use of AGVs. A variety of solutions are available for storage and retrieval: The manually operated pick-to-light rack helps the worker with controlled removal and storage, thus avoiding errors. The SMD BOX series helps to automate the storage and removal of materials, regardless of whether they are rolls, trays or moisture sachets (MSD). The SMD BOX MIMO / DUO is a compact tower storage system for up to 2,500 reels and can store and retrieve SMT reel material in a batch process. For this purpose, an AGV or trolley with up to 40 reels is driven into the loading opening of the system. A camera system then reads material information and updates the stock information in real time. The robot arm takes the registered materials to the assigned storage compartment. Only the roll ID or part number is required for material removal. A complete batch can also be selected using material or order lists. The SMD BOX unloads the required reels at the right time. The entire process is automated and even autonomous with the help of the SMF software. This means that any number of SMD boxes can be combined to form a flexible warehouse of any size. The SMD BOX XLR, which can store up to 14,400 reels, is also suitable for large storage capacities. The SMD BOX Inline is a suitable intermediate storage system for retrofitting placement machines. With integrated transfer, it can be integrated into the line to save space.

Traceability in the line

The traceability of the PCBs in the line is ensured by labeling using an A8500 Flexcell label print applicator from Brady. Several unique labels can be printed in this cell at a speed of 3 seconds per label. The accuracy of the application on the circuit board is +/- 100µm.

The area of paste printing and paste is still responsible for around 60% of errors in production. We show how these can be significantly minimized through the interaction of the SERIO 5000 printing system from EKRA and the solder pastes from Solder Chemistry. Solder Chemistry has developed an app for its customers in 2024 that helps with troubleshooting and can also be confronted directly with error patterns. Another important aspect is, of course, assembly. In FUJI's Smart Factory, automation is the overarching goal to free up manual operating tasks and to simplify and speed up processes. This also contributes to making SMT production more flexible. These tasks are supported by the new RH placement heads that FUJI is presenting at the trade fair. The traversing height of the placement heads can be adjusted with the help of a so-called Sub-Z axis. The contact sensor on the head is used to check whether the part has touched the PCB. The new RH placement heads are suitable for the R machine series (NXTR-A/-S and AIMEXR). By combining a newly developed 2RV module with RH28 heads, W08t feeders and MFU-63 feeder carriages, the NXTR delivers a throughput of 120,000 Bt/h (on 795mm module length) - this is an improvement of 39% compared to the NXT III placement machine.

For device underfill, Nordson Asymtek's Vantage liquid dispensing platform with IntelliJet underfill dispensing system is designed for high-end semiconductor packaging and microelectronics assembly. The fast and precise Vantage system, when configured with two IntelliJet valves, can apply in gaps of less than 200 microns and up to 90,000 dots per hour.

The demands of modern manufacturing

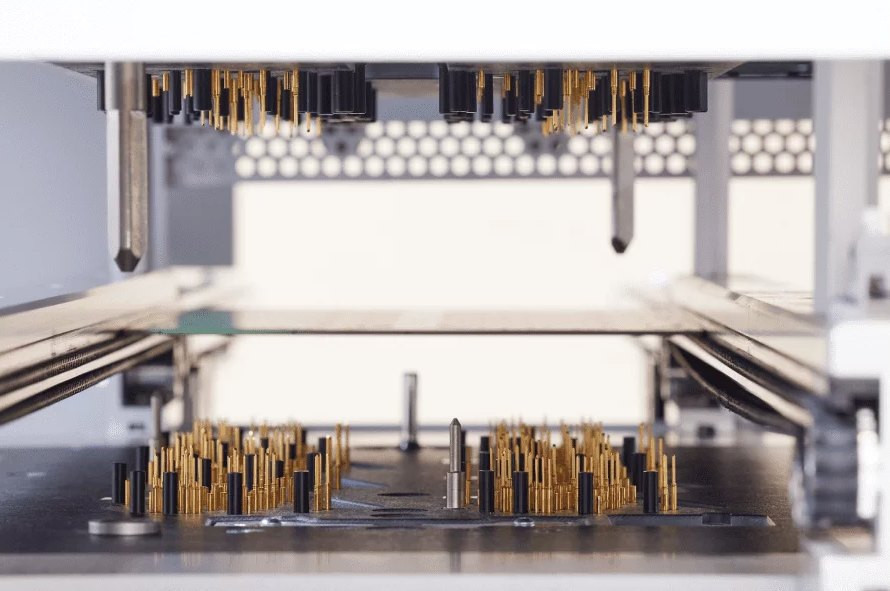

Engmatec test handler ETH in use

Engmatec test handler ETH in use

Of course, the manufactured assemblies also have to be tested. Testing printed circuit boards in the semiconductor industry requires precise test cells that enable various tests to be carried out reliably. The Engmatec Testhandler ETH offers a powerful and highly flexible solution for this. The robust and universal test cell was specially developed for in-circuit, functional and final tests as well as the programming of controllers (flashing) in the semiconductor industry and offers a variety of features and options that meet the requirements of modern production. The test handlers can be used as stand-alone systems or integrated into assembly and test lines and are connected to higher-level data systems such as MES or ITAC via interfaces. In addition, the Engmatec ETH test cell offers maximum flexibility through subsequent upgrading and adaptation to new requirements. Short set-up times, automatic change set insertion and interlocking as well as compatibility with all common test systems make it a strong solution for modern electronics production. Contacting, scanning, confirmation, readout and programming are carried out via interchangeable adapters. During testing, the PCBs or electronic products are contacted so that the measurement signals can be transmitted to a connected test system. An exchangeable, product-specific contacting adapter (interchangeable set) is used in order to be able to flexibly test different test specimens on the same system. This can be exchanged in a very short time, allowing the machine to be converted quickly and easily. The Engmatec test handler exchange kit offers a variety of interface blocks and enables a maximum contacting force of 6,000 N. Interfaces ranging from pylon, ODU, VPC and mixed forms to customer-specific interfaces are available.

Ulf Oestermann, Fraunhofer Institute for Reliability and Microintegration (IZM); Image: Fraunhofer IZMOf course,the machines and devices mentioned here represent only a very small part of the entire portfolio of the 'Future Packaging' line. The entire line and its 18 partners have much more to offer. A visit is therefore worthwhile for every visitor to SMTconnect. See you at SMTconnect in Hall 4, Stand 305. The line tours take place daily at 10 a.m., 1 p.m. and 3 p.m.! We look forward to an interesting trade fair and to welcoming many new and old faces to our stand.

Ulf Oestermann, Fraunhofer Institute for Reliability and Microintegration (IZM); Image: Fraunhofer IZMOf course,the machines and devices mentioned here represent only a very small part of the entire portfolio of the 'Future Packaging' line. The entire line and its 18 partners have much more to offer. A visit is therefore worthwhile for every visitor to SMTconnect. See you at SMTconnect in Hall 4, Stand 305. The line tours take place daily at 10 a.m., 1 p.m. and 3 p.m.! We look forward to an interesting trade fair and to welcoming many new and old faces to our stand.