With the Vitralit UD 1405 adhesive, Panacol has created a new bonding system for fiber winding technology: The UV adhesive can be used to wrap components such as rotors for electric motors and high-voltage arresters in a fiber-reinforced manner and these windings can then be cured with UV light. The process specialist Hönle offers the LED Powerline AC/IC 820 HP as a very suitable system for UV curing in these taping processes. The innovative taping process is extremely space and time-saving and therefore very economical to implement.

The solvent-free, one-component epoxy resin is transparent. It can be cured by UV/VIS radiation and can also be thermally post-cured. Due to its low viscosity, the new adhesive has very good wetting properties. This means that rovings made of GRP or CFRP, for example, can first be soaked in the adhesive bath, then wound onto the rotor or respective cylinder and then cured with UV or visible light.

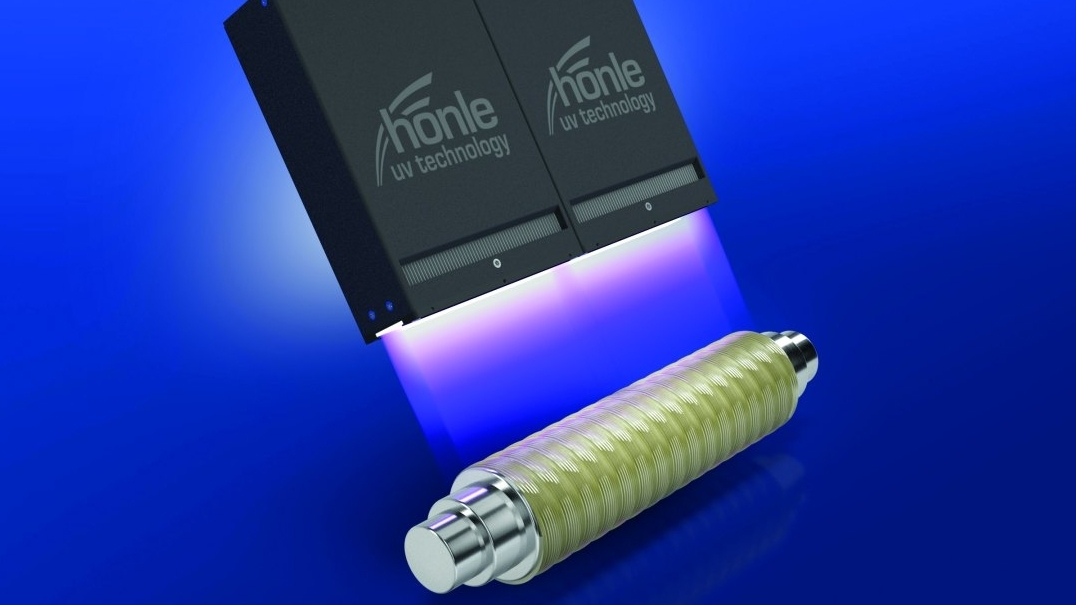

With intensities of up to 16,000 mW/cm², the Hönle LED lamp ensures very fast curing. Its light emission window is 82 x 20 mm or 122 x 20 mm, depending on requirements, and can be extended without gaps by stringing together several modules. When developing the LED Powerline AC/IC 820 HP, special attention was paid to a slim design. This makes it ideal for use in confined spaces, for example when curing during taping.

Panacol-Elosol GmbH is a company of the Hönle Group and is a supplier in the growth market for industrial adhesives with a wide range of products from UV adhesives to structural adhesives and conductive adhesives. Dr. Hönle AG, the parent company of the Hönle Group (headquartered in Gräfelfing near Munich), is one of the world's leading suppliers of industrial UV technology.