Nanosystec will be presenting two assembly systems for optoelectronic production at ECOC 2025 in Copenhagen at the end of September (29.9.-1.10): the NanoWeld laser welding station and the VersaHybrid multifunctional system. Both systems are characterized by precise process control and short cycle times.

The laser welding system was developed for the fully automated assembly of coaxial or linear opto-components such as butterfly modules, TO housings or TOSA/ROSA submounts. The system positions the components with minimal distortion, thereby increasing process reliability. Thanks to a hemispherical air guide, the components are contact-free and stable, while a symmetrical laser input ensures low thermal stress. This results in short cycle times and high stability during joining. The cycle times can reach >20 s, and up to 5 s when using the optional OptoSpin technology. Precise linear axes with 5 nm resolution, cross-roller guides and high-performance image processing ensure reproducible results and low rejects, even with high quantities.

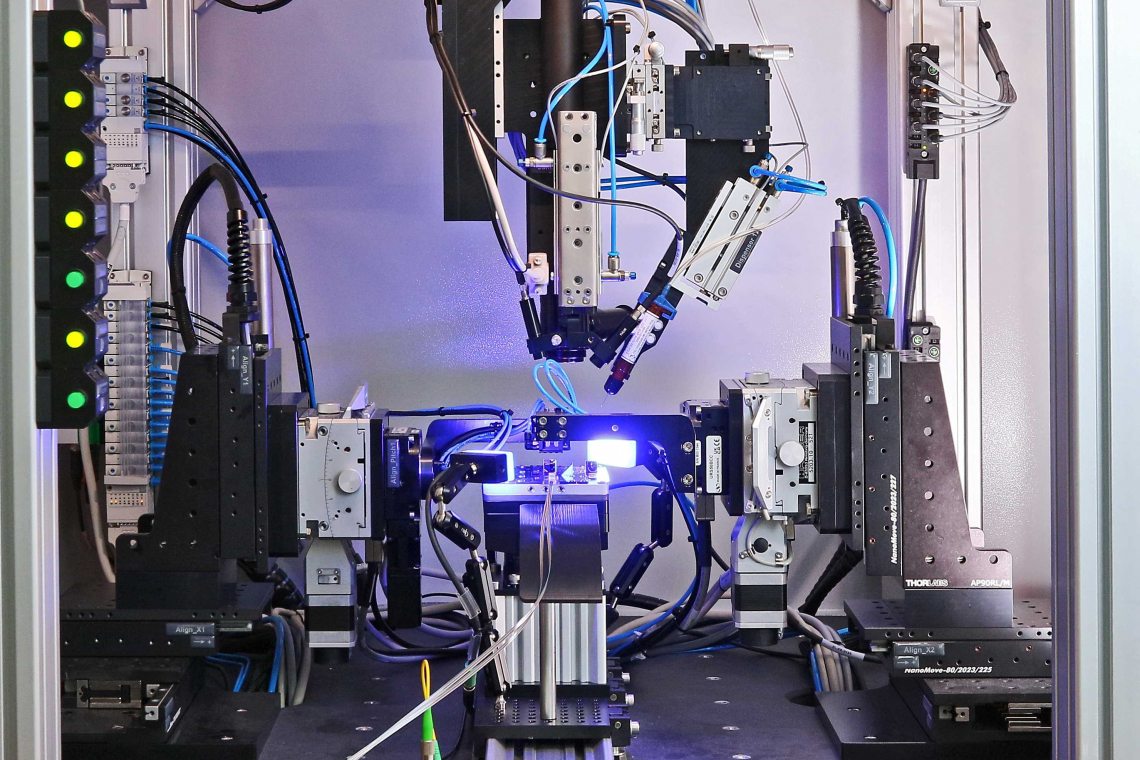

The modular VersaHybrid multifunctional system combines all micro-assembly processes on one system. Depending on the application, precision laser welding, selective laser soldering, UV bonding, laser fine cutting and active alignment can be combined without changing the system. The machine with its solid granite structure and stable portal design is equipped with linear axes with a resolution of 5 nm, enabling the precise positioning of the smallest components. Adaptive image processing with pattern and edge recognition ensures stable processes and flexible component identification, regardless of geometry or surface.

The system is suitable for small and medium-sized series as well as for 24/7 use in industrial series production. The company will be presenting its systems at stand C1411 at ECOC 2025 in Copenhagen.