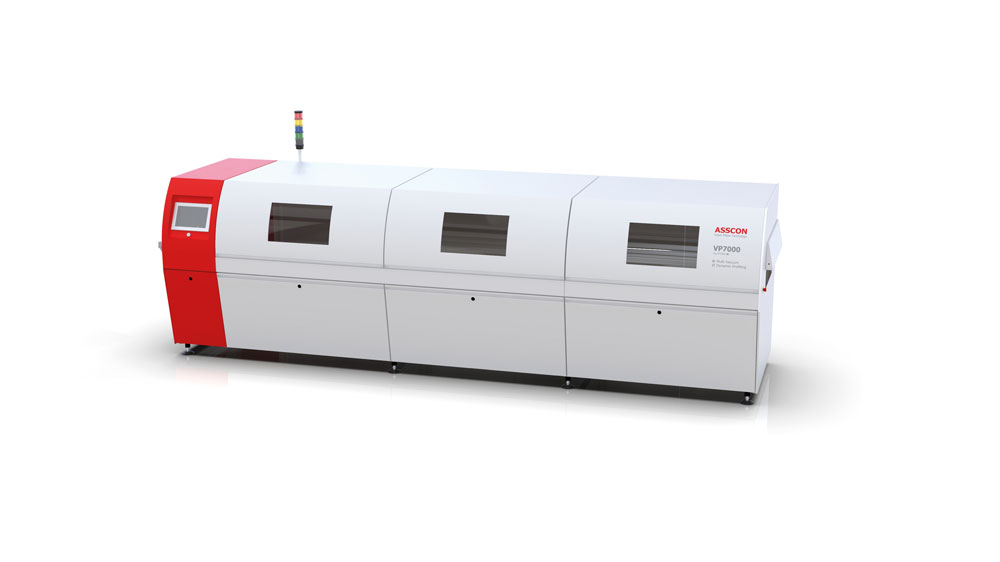

Asscon took part in Nortec in Hamburg in January and will be exhibiting at IPC APEX EXPO 2020 in San Diego in February 2020. As in Hamburg, the focus there will also be on the power-saving potential of vapor phase soldering systems. In view of the significant rise in energy costs in the future, the company is placing the considerable power-saving potential of inline vacuum vapor phase soldering systems at the center of its communications for the current year.

Asscon took part in Nortec in Hamburg in January and will be exhibiting at IPC APEX EXPO 2020 in San Diego in February 2020. As in Hamburg, the focus there will also be on the power-saving potential of vapor phase soldering systems. In view of the significant rise in energy costs in the future, the company is placing the considerable power-saving potential of inline vacuum vapor phase soldering systems at the center of its communications for the current year.

Exploiting the potential for saving electricity ultimately helps to reduce the global CO2 emissions permitted under the Kyoto Protocol. These are limited by the authorization to emit emissions, which in turn is controlled by emission rights. In future, companies will need these rights in order to be allowed to release carbon dioxide into the atmosphere. This is where the vapor phase soldering system offers a decisive advantage: it consumes much less energy than today's reflow ovens. On average, reflow ovens consume between 15 and 22 kW/h, while the vapor phase soldering system from Asscon requires a maximum of approx. 4.5 kW/h.

By participating in Nortec in Hamburg, the system manufacturer based in southern Germany wanted to demonstrate the advantages of vapor phase technology and enter into a direct exchange with customers and interested parties in the north of Germany. The advantages of vapor phase soldering include electricity savings as well as process simplification, stability and void avoidance.