4Source electronics procures original electronic components on the market, but also buys up residual quantities and stocks. Quality assurance checks the quality and quantity of the purchased stock before it is delivered. For all components whose innermost parts are not visible, X-ray inspection is used to x-ray the component and ensure quality through comparative analysis.

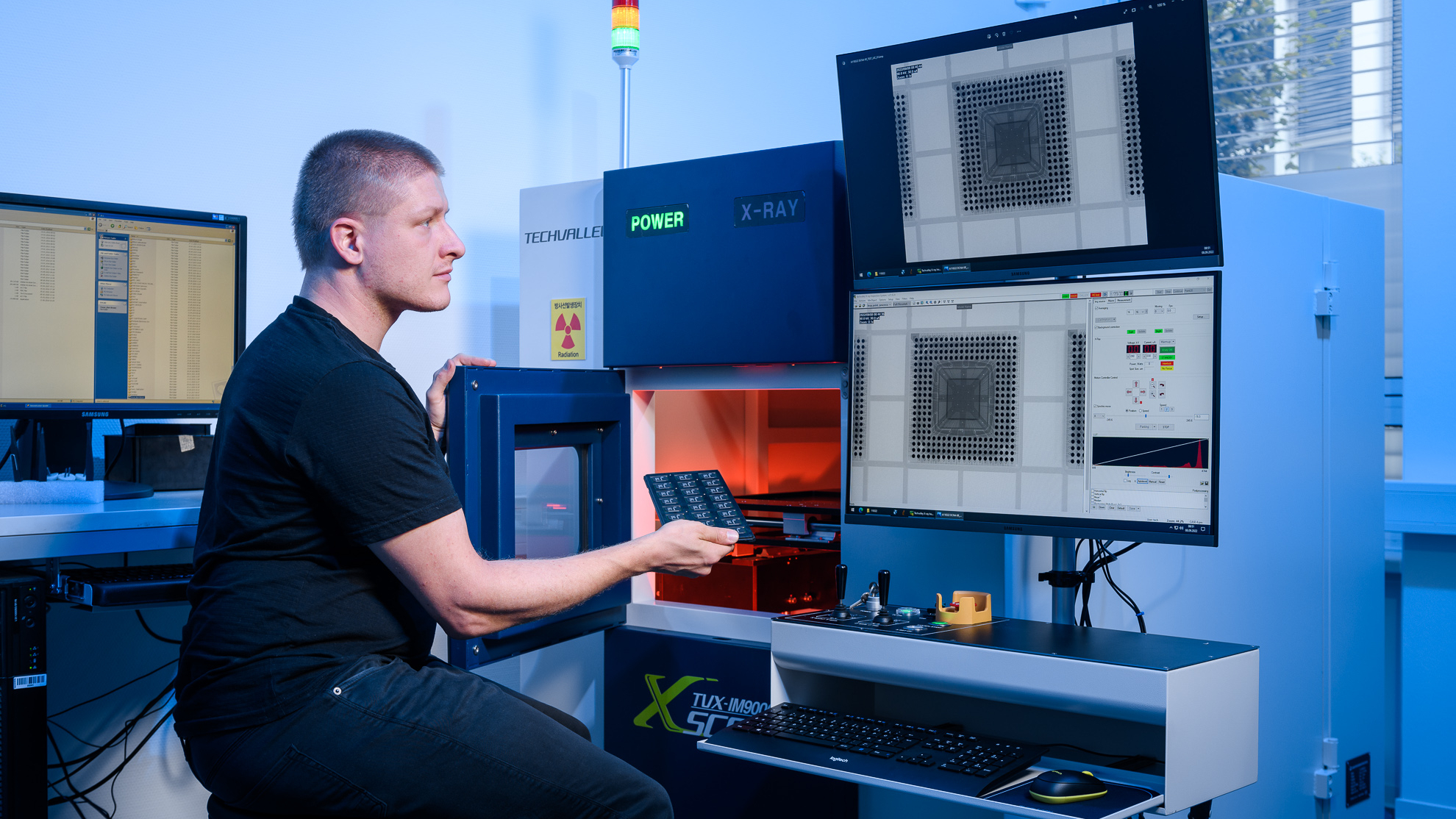

Due to the high demand for chips, the component procurer has now invested in a further X-ray inspection system for quality control, namely the AXI system IM9000 from the manufacturer TechValley with a 110 kV closed X-ray tube. The new system is characterized by high image data quality, various analysis options, high contrast depth and short throughput times.

An X-ray component counter, also from TechValley, has significantly increased the inspection speed of the incoming goods quantity. Whereas an employee needed around five minutes per roll with the mechanical counting devices, the counting and documentation process is now completed in ten seconds. The X-ray component counter automatically saves the results, including the X-ray image, in the database. The component rolls no longer need to be removed from the packaging before counting. This saves time and is gentle on the material.

Before the purchase, the quality team at 4Source electronics tested the component counter satisfactorily in the demo center of SmartRep, TechValley's distributor in Germany, to find out how the counter works with partial quantities, full rolls, very small components, very large components and special shapes.