The printed circuit board is the heart of almost every electronic device. It controls and monitors other components, such as motors, displays or sensors. These interfaces are subject to mechanical, thermal or chemical stress. Carefully selected and professionally executed connection technology can therefore be decisive for the service life, failure rate and cost-effectiveness of an electronic product.

The selection of the right connection technology depends not only on technical parameters such as current carrying capacity, contact resistance or mechanical stability, but also on factors such as assembly effort, repairability and costs. Basically, connection technologies can be divided into two categories: detachable and non-detachable connections.

1. detachable connection technologies

SMD connectorsDetachableconnection techniques are used wherever planned disassembly may be necessary - whether for maintenance, replacement or transportation. The connection is usually realized via a mechanical mating process.

SMD connectorsDetachableconnection techniques are used wherever planned disassembly may be necessary - whether for maintenance, replacement or transportation. The connection is usually realized via a mechanical mating process.

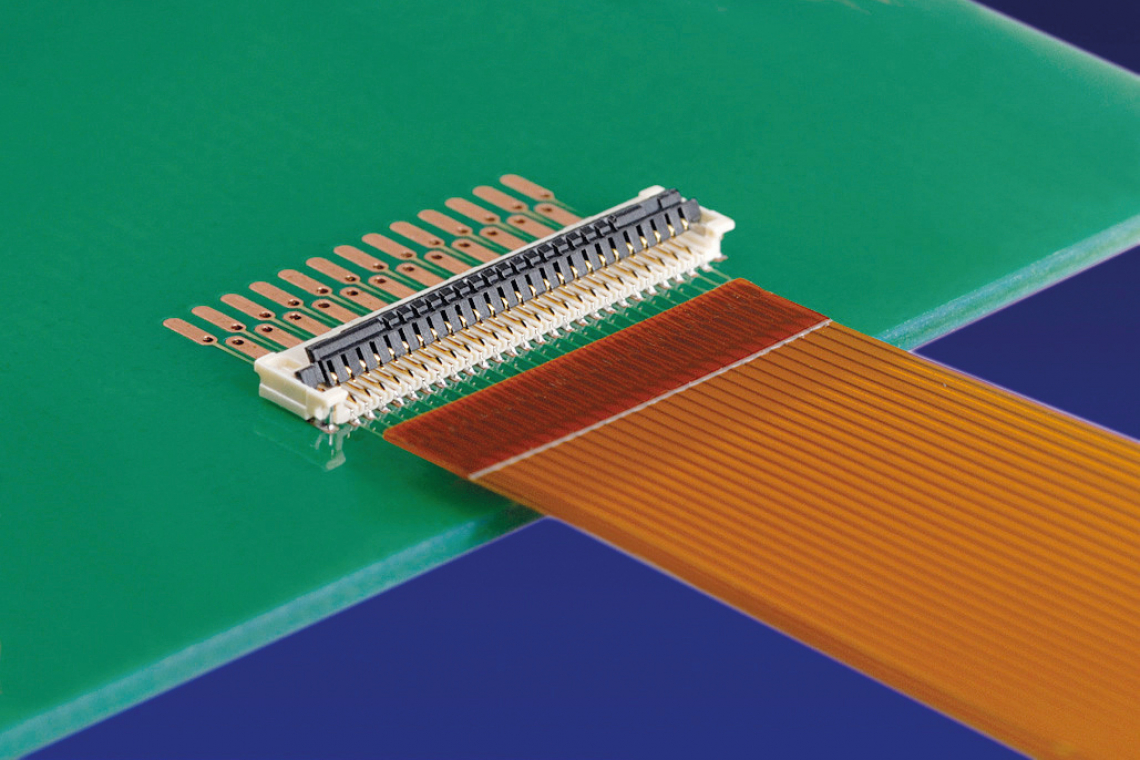

1.1 Zero-force connector (ZIF) or low-force connector (LIF)

A flexible printed circuit board (FPC) is inserted into a connector and partially mechanically locked. FPCs must have a minimum thickness of 0.3 mm (0.2 mm in exceptional cases) in the mating area.

1.2 SMD connectors

SMD connectors are soldered onto a PCB in a reflow oven. They are often used for FPC-to-PCB or PCB-to-PCB connections. The connector system consists of a socket housing on one side and the connector pins including housing on the opposite side.

1.3 Crimp connector

An FPC is contacted using a crimp contact and housing and connected to a mating connector. The crimping process always requires a suitable crimping tool and crimping equipment. The contact is gas-tight, which ensures a highly reliable connection.

1.4 Edge connectors

The contact pads on the edge of a PCB are gold-plated and inserted into an edge connector soldered to the main PCB. This technique is often used for expansion cards, backplanes or modular systems.

1.5 Pogo pins

Pogo pins are spring-loaded contact pins that are used for temporary connections - for example in test adapters or docking stations. They allow fast, repeatable mating cycles without major wear on the mating contacts.

2. non-detachable connections

Non-detachable connection technologies are used where a permanent and corrosion-resistant connection is required.

2.1 Press-fit contacts

Press-fit contacts are pressed into metallized vias of a printed circuit board without the influence of temperature. The mechanical pressure creates a gas-tight, cold-welded connection. A suitable press and an individual press die are required for the process.

2.2 Solder connections

THT connector solder connectionsare among the most widely used connection techniques. They enable both electrical and mechanical fixation. A distinction is made between

THT connector solder connectionsare among the most widely used connection techniques. They enable both electrical and mechanical fixation. A distinction is made between

- Wave soldering: Through-hole contacts (THT), which are selectively soldered via a solder wave. THT soldering results in higher mechanical strength and is used particularly for large or heavy components

- Reflow soldering: efficient and precise soldering process for mass production and especially for a high number of components

- Iron soldering: Sensitive soldering process between FPC and PCB using an iron soldering system with precise temperature and time monitoring as well as special tools, not mechanically resilient

2.3 Welding techniques

Ultrasonic or resistance welding processes are used in power electronics in particular, for example to connect conductor tracks to busbars or high-current connections. A special form is bonding, in which a bonding wire is welded onto a contact point.

2.4 Adhesive connections

Electrically conductive adhesives (e.g. anisotropic liquid adhesives or conductive adhesive tapes) are used for bonding many contact points, although the current carrying capacity is very low.

3. conclusion

Choosing the optimum connection technology for PCBs requires careful consideration of mechanical, electrical and economic requirements. While detachable connections primarily offer ease of servicing, non-detachable technologies score points with their mechanical load capacity and higher current transmission. In addition, the associated unit costs and the necessary investment in plant and equipment must be taken into account when selecting the connection technology.

4 Application cases for connection technologies

4.1 Connector technologies

- ZIF and LIF connectors are used in various areas, including display connections and general plug connections in automotive, consumer and medical technology.

- SMD connectors are mainly used in long-life applications such as machine technology and medical devices.

- Crimp connectors are often used in the automotive sector, for example for FPC connections in battery control systems or machine control systems where high vibration resistance is required.

- Edge connectors connect several PCBs within a device, for example in machine control systems.

- Pogo pins are used in test adapters, among other things.

- Press-fit contacts are used in products with high vibrations and damp environments.

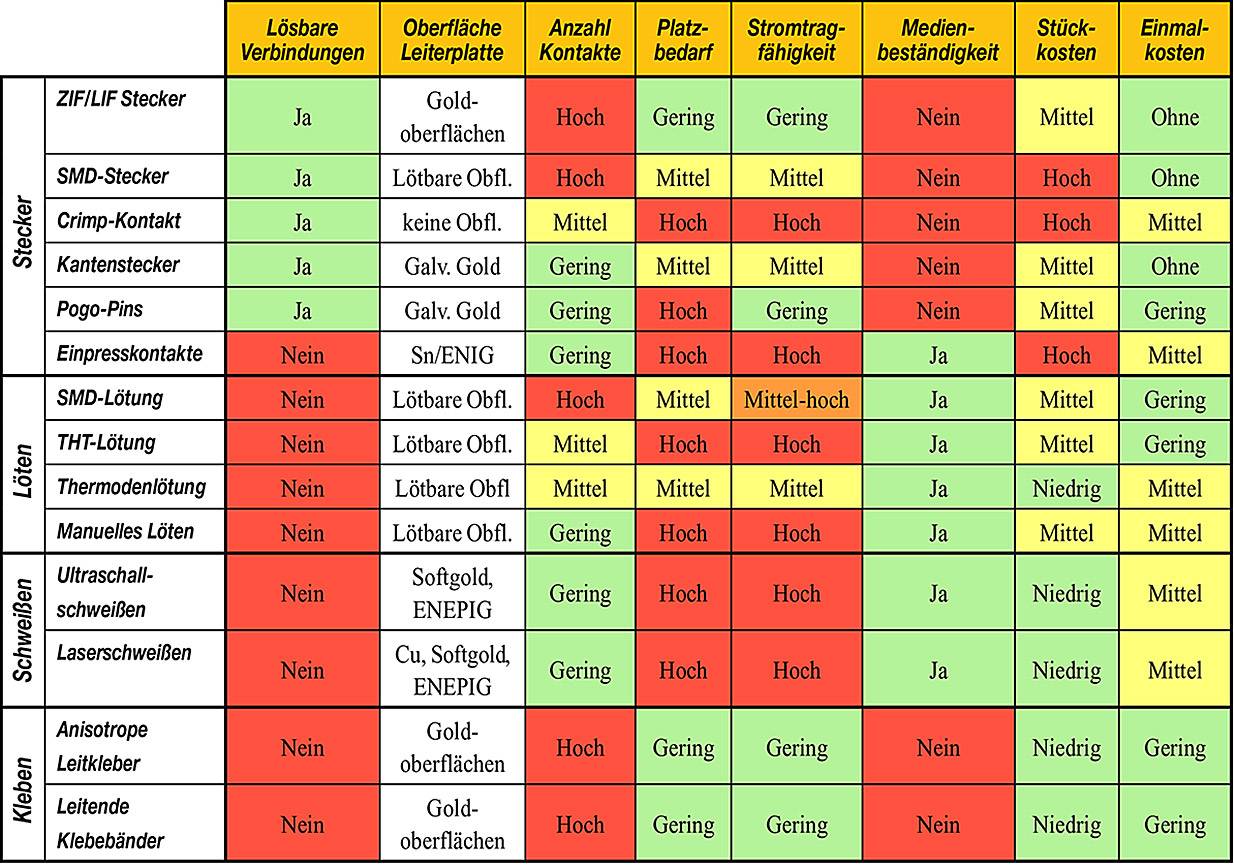

Tab. 1: Overview of connection technologies for printed circuit boards

Tab. 1: Overview of connection technologies for printed circuit boards

4.2 Soldering

- SMD and THT soldering is used to assemble electronic components. SMD soldering is used in particular for small components and high quantities without mechanical stress, e.g. on control or sensor boards in the automotive environment or for general applications.

- Bracket soldering is a specialized solution for the permanent connection of FPCs to printed circuit boards.

4.3 Welding

- Ultrasonic and laser welding often join PCBs, especially FPCs, to solid components such as stamped parts or busbars. Wire bonding technology enables the direct contacting of bare chips with printed circuit boards.

4.4 Bonding

Printed circuit boards, especially FPCs, are bonded to control boards for contacting display connections. This technology is used in all industries and applications.

About the person

Markus Voeltz, Director Business Development at CEE PCB, is a business development expert with over 30 years of sales experience, including more than 20 years in the PCB industry. He has worked with customers to develop many efficient, reliable solutions in the consumer, automotive, industrial and medical technology sectors.