Researchers from Germany, Italy and the UK have taken an important step in the development of a thermoelectric material that could enable energy recovery directly on the chip in the future. The alloy of germanium and tin appears to be suitable for converting waste heat from processors into electricity.

Researchers from Germany, Italy and the United Kingdom have taken an important step in the development of a thermoelectric material that could enable energy recovery directly on the chip in the future. The alloy of germanium and tin appears suitable for converting the waste heat from processors into electricity.

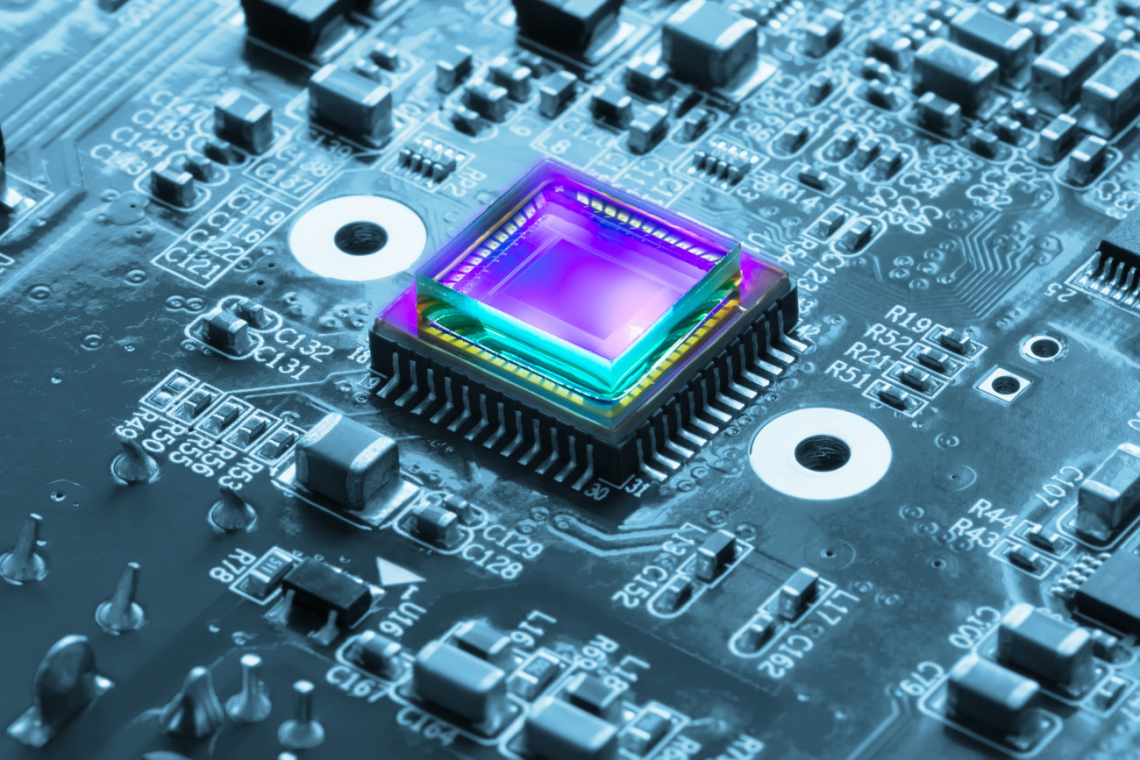

The increasing use of electronic devices in all areas of life is driving up energy consumption. A large proportion of this energy is released into the environment in the form of heat. In Europe, around 1.2 exajoules, or 1018 joules, are lost each year from IT infrastructures, data centers and electronic devices. This is roughly equivalent to the primary energy consumption of Austria. This heat at temperatures below 80 °C is difficult to use due to its poor thermodynamic efficiency and technological limitations. However, attempts could be made to recover the low-temperature heat. But there are very few materials that are capable of converting the heat into electrical energy, and none of them are compatible with current technology in semiconductor manufacturing plants. However, a collaboration between Forschungszentrum Jülich and the IHP (Leibniz Institute for Innovative Microelectronics) from Germany, together with the University of Pisa, the University of Bologna from Italy and the University of Leeds from the UK, has now made significant progress in developing such a material that is suitable for energy harvesting on chips and compatible with the CMOS process of chip manufacturing.[1] As all elements are from the 4th main group of the periodic table, the new semiconductor alloy can be easily integrated into the CMOS process of chip manufacturing. The research results made it onto the cover of the scientific journal 'ACS Applied Energy Materials'.

Leibniz Institute IHP in Frankfurt (Oder)

Leibniz Institute IHP in Frankfurt (Oder)

Subject and results of the research work

The researchers found that adding tin to germanium significantly reduces the thermal conductivity while retaining the electrical properties. The experimentally confirmed low thermal conductivity of the crystal lattice explains the great potential of GeSn alloys as a thermoelectric material. By integrating it into silicon-based microchips, it is possible to utilize the waste heat generated during operation and convert it back into electrical energy. This 'energy harvesting' on the chip could significantly reduce the need for external cooling and electricity. Group IV elements in the periodic table, also known as the silicon group, form the basis of electronic devices. By combining them into alloys, the areas of application are extended to thermoelectrics, photonics and spintronics. In the long term, the integration of photonics, electronics and thermoelectrics on the same chip with silicon-based technology is therefore within reach. This would not only improve the performance of the devices, but also support the development of more sustainable technologies. The research evaluated one of the most critical parameters for a thermoelectric material, thermal conductivity, by applying and testing a number of different experimental techniques on epitaxial samples with different alloy compositions and thicknesses.

How does a thermoelectric element work?

Thermoelectric elements convert temperature differences directly into electrical energy. An existing temperature gradient stimulates a flow of electrical charge carriers and thus generates an electric current. This process can be used to utilize waste heat in electronic devices, converting it into usable energy and reducing overall energy consumption. Low thermal conductivity is desirable for thermoelectric materials as it allows for a greater temperature gradient, which in turn is crucial for efficient energy conversion. GeSn alloys, with their low thermal conductivity, appear particularly suitable for creating such a temperature gradient.

Outlook

The research groups at Forschungszentrum Jülich and IHP are continuing their collaboration to further develop the material. The aim is to extend the composition of the alloy to silicon germanium tin (SiGeSn) as well as the ultimate Group IV alloy with the addition of carbon (CSiGeSn) and thus produce a functional thermoelectric device that can be used to demonstrate the potential of energy generation using Group IV alloys. The activity is financially supported by a newly awarded DFG grant.

Literature

[1] Omar Concepción, Jhonny Tiscareño-Ramírez, Ada Angela Chimienti, Thomas Classen, Agnieszka Anna Corley-Wiciak, Andrea Tomadin, Davide Spirito, Dario Pisignano, Patrizio Graziosi, Zoran Ikonic, Qing Tai Zhao, Detlev Grützmacher, Giovanni Capellini, Stefano Roddaro, Michele Virgilio, Dan Buca, 'Room Temperature Lattice Thermal Conductivity of GeSn Alloys', ACS Appl. Energy Mater. 2024, 7, 10, 4394-4401, https://doi.org/10.1021/acsaem.4c00275 (accessed: 28.10.2024).