During a company visit to Alzenau, PLUS met with Harald Eppinger, Managing Director of Koh Young Europe, for a lengthy discussion. The result was an interesting reflection on the development of 3D AOI systems, advanced packaging, changes in the semiconductor market and the differences between German and Korean corporate culture. At the same time, Harald Eppinger talks more openly than ever about his career. The interview was conducted by Markolf Hoffmann.

PLUS: Mr. Eppinger, how did your path lead you into electronics?

Eppinger: It was actually a very classic career. I started my training as a precision electronics technician at Siemens in 1976. Electronics and its innovations have always inspired and driven me, and at the time, training at Siemens was practically the law.

Did your interest in electrical engineering come from your family?

My father was a businessman and had nothing to do with the field. But as a teenager, I was enthusiastic about model airplanes and amateur radio - at that age, you show a lot of creativity. I was enthusiastic about electronics, and I still am. When I see young people entering the world of work today, I have to say that they have completely different opportunities. A computer hard disk used to cost a lot of money and had 10 MB - today you can store 1 TB of data on your cell phone. I have a great affinity for technical gadgets. I still get excited when I discover something new.

Harald Eppinger presents the NEPTUNE C+ for 3D In-line Dispensing Process Inspection (DPI)

Harald Eppinger presents the NEPTUNE C+ for 3D In-line Dispensing Process Inspection (DPI)

Let's go back to your beginnings at Siemens ...

I did a mechanical and electrical engineering apprenticeship there. After graduating, I went to the Siemens Bruchsal plant: switching technology, EWSD ... that was high-tech at the time. In Bruchsal, I then worked in the test field with in-circuit test systems and functional testers. That was my springboard into measurement technology.

"You could feel it, you could see it: this can change everything!"

What was your next step?

During those years at Siemens, there were repeated job cuts, including in the field of measurement technology. That's why I moved on - from Siemens to Schroff. Schroff is normally known for its 19″ technology, but at the time it was also responsible for the whole issue of power supply units and power supply for these racks. I came from digital technology, so I thought in zeros and ones ... and was now working in analog power supply technology. I was now dealing with completely different products. I started at Schroff because the topic of in-circuit testing was implemented there. I then came to Schuh, an experienced supplier in the field of electrical component testing, via Wayne Kerr and surge testing. I couldn't let go of the subject of testing - I always wanted to get better at finding faults in electronics. However, miniaturization continued to advance. Of course, the miniaturization of the past and the miniaturization of today are worlds apart. At Schuh, however, it was already said that testing with needles would soon no longer be enough. So the first 2D AOI systems were developed, and Schuh launched its own on the market in 1987.

The classic 2D optical quality assurance ...

Yes, and it stayed with me for a long time. Schuh was later taken over by the Israeli electronics company Orbotech. Orbotech then globalized Schuh as a German company and brought the products out into the world. At that time, there were only three, four or five players on the AOI market, and that's how my business came about, my responsibility for technical applications, technical sales and product management.

How did you come to Koh Young?

At some point, the question arose: What is my next step, what happens next in this area? Koh Young approached me at the time. At first I waved it off: that doesn't suit me, it's not a challenge. Paste inspection seemed too easy for me. It took me a while to recognize the potential. When I came into contact with Koh Young, the company had been in existence for about ten years and was at a crossroads. The demand in Europe was growing. Koh Young had a European distributor, Pete Stins, but that was not enough to cover the huge market. So the decision was made in South Korea to do it right and expand the distribution channel. The plan for 2009 was to set up Koh Young Europe as a limited company. That was my start.

"The technology was already with us."

Why did you decide to join Koh Young?

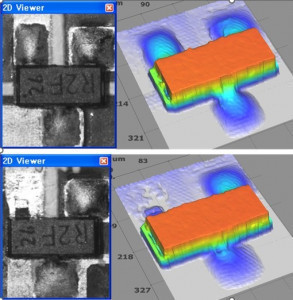

This picture immediately convinced Harald Eppinger of the technical innovation of the 3D-SPI- he was shown a photo by a former colleague who was already at Koh Young: Comparing 2D inspection and 3D inspection ... it knocked my socks off. It showed the SOT 23 transistor - one of the worst components for AOI at that time. I'm sure people laugh about it today. But it's true: no matter how SOT 23 was soldered to the circuit board - across, straight or upside down - it always looked the same in terms of the picture. This photo comparison was so significant that I only asked my former colleague one question: "Is that real?" He nodded. Then all I said was: "OK, where do I have to sign?"

This picture immediately convinced Harald Eppinger of the technical innovation of the 3D-SPI- he was shown a photo by a former colleague who was already at Koh Young: Comparing 2D inspection and 3D inspection ... it knocked my socks off. It showed the SOT 23 transistor - one of the worst components for AOI at that time. I'm sure people laugh about it today. But it's true: no matter how SOT 23 was soldered to the circuit board - across, straight or upside down - it always looked the same in terms of the picture. This photo comparison was so significant that I only asked my former colleague one question: "Is that real?" He nodded. Then all I said was: "OK, where do I have to sign?"

What convinced you so much?

The picture was an eye-opener. When you look at it, you'll agree with me. The wow effect of the 3D view was enormous. After struggling for so long with issues such as false alarms, slippage, programming time, individual programming etc., this process offered a completely new basis. You could feel it, you could see it: it could change everything! Of course, it was an absolute niche at the time. Everyone said to me at the time: "That's SPI ... and 3D inspection is a niche product." But this powerful technology, this underestimated niche product, soon became a disruptive innovation. In 2003, Koh Young launched his SPI on the market with this revolutionary change - the leap from 2D to 3D. And so the circle closes. The entire approach was different: it was no longer about classic image processing, it was about measuring. The question was no longer whether and from which direction the light was falling, whether one or the other area was brighter or darker. Instead, we talked about mm or µm, and whether this corresponded to a tolerance percentage or not. A world has opened up in this area.

How quickly did this realization take hold?

To my astonishment, it was difficult to convince the conservative electronics market of this technology. Today, 3D has become a global standard. The trigger was actually to bring 3D measurement into the AOI world. I was excited to bring this innovation to the market.

Speaking of the market as a whole, you mentioned the increased demand for semiconductors in 2022 and suggested that the advanced packaging sector will grow significantly. How do you think this huge demand can be met?

At Koh Young, we have a lot of experience with back-end and advanced packaging. The Asian markets have served the whole world. But then came Covid, then came the supply chain bottlenecks ... suddenly everyone was thinking about why all this was happening. In my view, a lot of it was homemade. First and foremost, I would mention regulations and the trade conflicts between China and the USA. This has created a different awareness and people are now trying to bring back production. You have to realize that these products used to be here. It's not really the case that they are completely new territory for us. You only have to look at older issues of your magazine: the technology has been here before. Strictly speaking, it's still here, but not the production. The markets have shifted. The fact that this dependency has been brought home to us as it has in recent years has shaken our conservative market. This is why initiatives such as the Chip Act were launched in the USA and Europe. There has been significant movement in the market.

How do you think this development will continue - and what difficulties do you anticipate?

We passed the Chip Act in America and Europe more or less at the same time. It was clear that we had to do something and the money was made available. But in America, production is already ready to move in, whereas in Europe it takes longer to find the right location and complete the processes and implementation. It should actually be clear that politicians need to do more to support the initiatives. As we all know, time is money, and if we assume today that the major manufacturers will only go into operation in two to three years, a lot of time will be lost. However, in my presentations I point out what the market is already capable of. We at Koh Young have been doing what we do for a very long time. And that applies not only to us as suppliers, but also to our customers. Many only pay attention to large investments. Yet a healthy SME sector in Germany is the cornerstone of our economy.

In PLUS, we report in detail on the large chip production facilities that are currently being built or are planned: Intel in Magdeburg and in Leixlip (Ireland), Infineon in Dresden, TSMC in Dresden (in cooperation with Bosch, Infineon and NXP), Wolfspeed and ZF Friedrichshafen in Ensdorf (Saarland), Globalfoundries and ST Microelectronics in Grenoble (France) and so on. What opportunities are opening up here for Koh Young Europe?

Many small and medium-sized companies, products, niches and business potential will emerge around the 'big players'. This is why we have taken the initiative and are offering our expertise. Koh Young has been catching up in Asia for seven or eight years. Now the market is growing here and so is the demand for our machines, which we have been offering for a very long time and which are available here. We are ready for the current and highly exciting developments. I would also like to mention our cooperation with partners in the market, such as Koenen, Semi and EKRA. We try to share know-how with everyone who plays a role - not just in the semiconductor sector.

How do you assess this glut of new chip fabs in Europe?

The fact that the big names you mentioned are so active is of course due to the chip shortage and the headaches it causes. But there is also an emerging trend in advanced packaging to move closer to the semiconductor manufacturers. Chips are being offered with new functionalities that change and improve complexity beyond belief. This advanced packaging is replacing the large printed circuit boards of the past. Today, their functionalities are placed on a postage stamp. At first glance, the resulting products look like semiconductors. But if you look at them under a microscope, you realize that they are printed circuit boards: green, densely packed and ultra-complex. This is where we come in with our expertise in the field of SPI / AOI of the classic PCB, which we have brought to the market - not only as a system supplier, but also as a partner. You don't have to reinvent the wheel every time. We want to offer seminars and workshops and inspire confidence in our manufacturing expertise. A huge market is emerging, which will not only, but also in Europe. If Germany does its homework, a large part of it can also be created here.

"A healthy SME sector in Germany is the cornerstone of our economy."

You probably think that politicians should do more. However, it's not just new chip factories that are emerging, but also new regulations that pose challenges for the industry ...

"There is a world of difference between the miniaturization of the past and that of today": Harald Eppinger in conversation with PLUSWein Europe are known for rules and standards. Sometimes this makes us a little slow in global competition. There is currently an opportunity for Germany and Europe to regain a foothold in areas that have been lost. However, if we are not careful, one or two companies will decide to move to another region. Politicians should therefore provide even greater support. Not just in monetary terms ... Companies depend on a 'friendly environment'. Too many rules are not helpful. Many people from abroad - including in our Group - sometimes don't understand that we have so many regulations. However, I would like to say that it's not all bad. It's good to know the exact framework within which you operate. At the same time, such a framework can slow down the momentum.

"There is a world of difference between the miniaturization of the past and that of today": Harald Eppinger in conversation with PLUSWein Europe are known for rules and standards. Sometimes this makes us a little slow in global competition. There is currently an opportunity for Germany and Europe to regain a foothold in areas that have been lost. However, if we are not careful, one or two companies will decide to move to another region. Politicians should therefore provide even greater support. Not just in monetary terms ... Companies depend on a 'friendly environment'. Too many rules are not helpful. Many people from abroad - including in our Group - sometimes don't understand that we have so many regulations. However, I would like to say that it's not all bad. It's good to know the exact framework within which you operate. At the same time, such a framework can slow down the momentum.

Some fear that Germany could remain a pure chip supplier. So far, no new PCB production facilities have been created. How do you assess that?

We have seen major changes in PCBs over the years. They are becoming more and more densely packed and compact, the functionality in a small space is changing ... this shows that there is a need. We are currently seeing the return of the semiconductor. The next door could open soon and the PCB could also return. I clearly propagated this at the last Semicon Europa. If we open our eyes, we can see that markets that were previously specifically in China are no longer there. They are leaving China. If an appropriate environment is created here, the PCB will also come. In concrete terms, companies that previously invested in China will reorient themselves. At the moment, the focus of investment is still on India and South East Asia. But companies will also dock in Europe.

A very promising statement ...

I actually take a very positive view of all this. Lines that were not even remotely planned are suddenly popping up in or near Europe. In Morocco, in Serbia, in Macedonia ... and to some extent in Germany too. Of course, labor costs are higher here and the general conditions are more difficult. Perhaps 20% of our new investments are in Germany and 80% in other European countries. That could still change, for example if the infrastructure and other factors become more attractive for manufacturers.

It sounds as if you are recommending a little more courage to the industry ...

Yes, courage and confidence in our expertise. 'Made in Germany' used to be really big and is still very popular. Europe as a whole has a strong branding. 'Made in Europe' is now also available as a logo. I think we just need to become aware of our roots. Good technology and high-tech have always been developed and produced in Europe, especially in Germany. We need to rediscover that.

Koh Young's headquarters are in South Korea, with Dr. Kwangill Koh at the helm. In your experience, how does Korean company management differ from German management? What mutual enrichment is there and what peculiarities of the two cultures clash?

Of course there are differences between an Asian-managed group and European company structures. We Europeans, especially us Germans, tend to be more straightforward, we want to think everything through and already have a plan B and plan C in our pockets for everything. This gives us a certain level-headedness - especially if you've been in the industry long enough. Then you know that one thing won't happen so quickly and another thing can't be pulled off the fence. On the other hand, we see the dynamic Korea. Dynamic Korea' was actually once an advertising slogan. The country and its culture have an incredible ability to change. It is a challenge for us to bundle this dynamism properly. At Koh Young Europe, the task now is to combine 'Dynamic Korea' with European prudence. If you use the right communicators, you can create an incredible synergy.

What mistakes should be avoided?

If you want to bring everything that comes from Korea 1:1 to Europe, or in the opposite direction, bring an idea from Germany 1:1 to Korea, then it will crash. Simply copying culture, behavior or structures can't work. When I started at Koh Young, I was given the confidence to make the right decisions. The motto was: We do it the way your market needs it - to gain a foothold as a Korean company in Europe. There is strong competition in Europe and in Germany. As a foreign company, Koh Young was a 'no name' - and SPI / AOI was still in its infancy. Nevertheless, we have managed to develop this enormous presence. This would not have worked with a copy & paste strategy.

It sounds like you took exactly the right path with Koh Young Europe.

When I look back on my career as a whole, this is my most fruitful collaboration - with a result that fills me with pride. We have contributed to the success here in Alzenau, and our test boards are also used on the machines and in the laboratories in Korea. It's not a one-way street, but a sign of the close ties between the different parts of the company.

What can visitors to the Koh Young stand at productronica expect?

Our entire product portfolio will be presented. Once again, it's all about production automation and process visualization - with a clear focus on the classic PCB: KSmart, KPO Printer, KPO P&P. We will also be addressing the key trends of the moment: Semiconductors and Advanced Packaging. Coating, underfill, packaging, wafer bumping - everything that is important for semiconductor production appears on the screen of our machines. These new approaches will fascinate all visitors. We look forward to finding out from them at the trade fair how they envisage their production in the future. Perhaps we can help.

Hall A2, Stand 359 + 377