The Fraunhofer Institute for Reliability and Microintegration IZM is researching a new method that will enable complex electronic systems to monitor themselves. In future, so-called grey box models will be used to detect signs of wear or manipulation in electronic systems before a failure occurs.

The new process is currently being developed and tested for the first time using the example of safety-critical applications in the automotive and rail sectors. However, the basic principle can also be transferred to many other areas of application.

Vehicles contain more and more electronics that have to withstand extreme loads over a long period of time. To ensure the reliability of the electronics, overdesign and redundancy have often been used in the past: Electronic systems or parts of them are installed in duplicate, for example, so that if a fault occurs, the stand-in electronics can take over until the problem is rectified.

In the 'SesiM' project, which has been running under the leadership of Siemens since 2021, researchers at the institute and other partners are using the example of cars and trains to investigate how complex electronic systems can validate themselves, i.e. evaluate themselves and communicate how well they are functioning - e.g. via an integrated traffic light system. It is less interesting whether the electronics are broken or not, as certain functions may already be impaired before a system fails, for example if materials become brittle. Such signs of ageing can often only be recognized very late by the mechanical stability of the component.

Grey box models as a combination

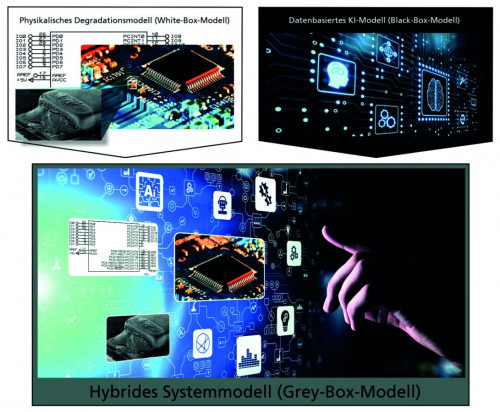

Hybrid models combine the advantages of physical and data-based modelsTheproject participants see the key to effective self-validation in so-called grey box models. These are so called because they are based on both white-box and black-box approaches.

Hybrid models combine the advantages of physical and data-based modelsTheproject participants see the key to effective self-validation in so-called grey box models. These are so called because they are based on both white-box and black-box approaches.

White-box models are those whose functionality is easy to understand on a physical level. Researchers at IZM are able to create such models for determining and predicting states based on physical processes and modeling boundary conditions such as temperature or humidity.

With complex electronic systems, however, it is difficult to record and monitor them purely at the physical level. For such complex systems, models based on statistics and large amounts of data are used, among other things, which utilize artificial intelligence methods. However, what physically happens within the system remains unclear - hence the name black box model.

Grey box models now combine both types of modeling. On the one hand, this hybrid modeling allows a great deal of data to be processed and intelligently evaluated. At the same time, the underlying physical processes can also be recorded and understood in the event of changes in the signal. This significantly increases the quality of the available data.

From test circuit boards to prototypes

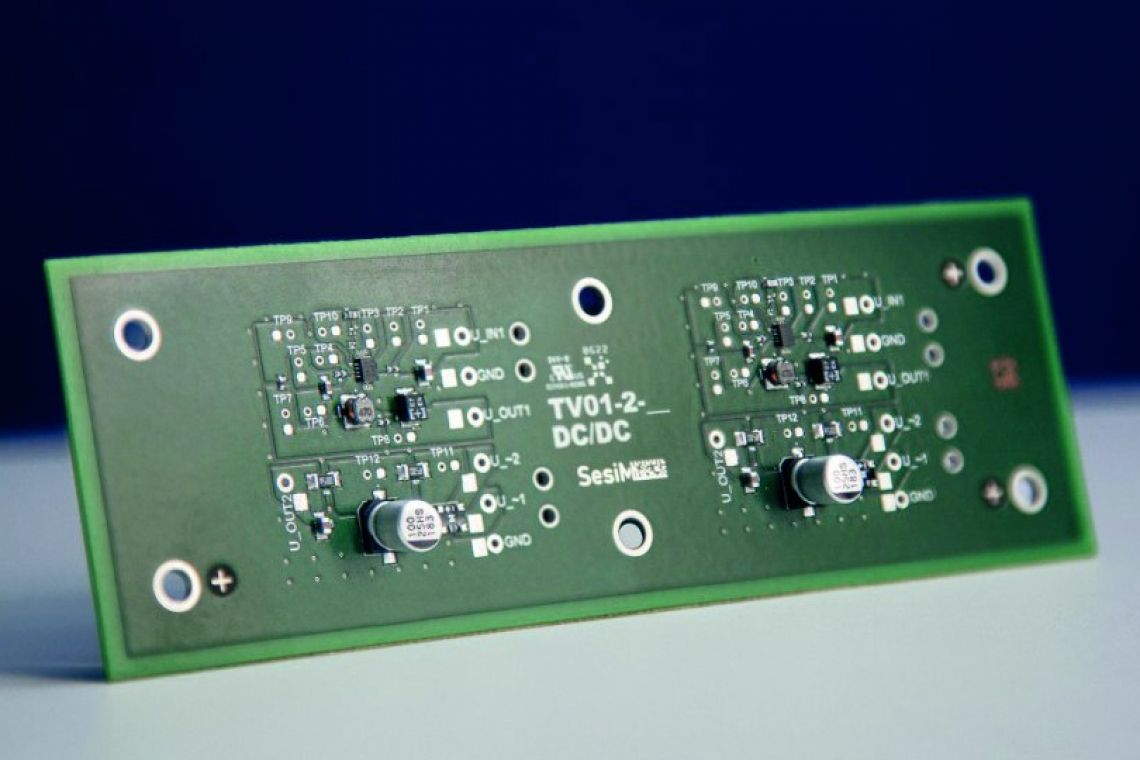

Grey box models are still largely uncharted territory in practical applications. For this reason, the researchers in the project are currently working on the description of simple circuits after the conception phase, which will become more complex over the course of the research project. The test circuit boards will be precisely measured and tested during production and in operating condition as well as under extreme boundary conditions. This creates a digital fingerprint of the test circuit.

The next step is to identify those parameters within the huge amounts of data that are really relevant for the representation of the system. A model is then created from this, taking physical knowledge into account, which recognizes deviations from a previously defined ideal state. The aim is to detect external manipulation quickly and predict signs of wear at an early stage. The plan is to later transfer the test circuit boards into prototypes for automotive and rail applications and to evaluate the models created using these.

Potential for broad application

A follow-up project will focus on aviation. However, applications outside the mobility sector are also conceivable, for example in medical technology or in remote wind turbines, which are difficult to access for regular external monitoring and preventive maintenance. However, the primary aim of the project is first to prove that the basic principle of self-validation of electronic systems using grey box models actually works. If this is successful, the reliability of electronic systems can be significantly increased in the future.

The SesiM project was launched on July 1, 2021 with the partners Siemens, Robert Bosch, Aucoteam, Göpel electronic, Gestalt Robotics and the University of Stuttgart.