Anyone who has ever tried to have a faulty electrical appliance repaired will have experienced that it is not that easy. There is a lack of spare parts and skilled workers, and service technicians often send you away because the repair costs are no longer worth it. But this is changing - thanks to EU regulations and innovations from the manufacturers themselves.

Thanks to the EU Ecodesign Directive, stricter requirements for household and consumer appliances have been in force since March 1, 2021, which should make repairs easier and therefore more attractive for consumers. This is also a trend among the population: according to a recent survey (Eurobarometer 04/2022), almost 80% of Europeans would prefer to have their electrical appliances repaired rather than having to constantly buy new ones.

Manufacturers are now obliged to design their appliances in such a way that repairs can be carried out using 'standard tools' without damaging the housing. Spare parts must be easily obtainable, available over the long term and deliverable at short notice (within a maximum of 15 days). In addition, 'technically competent repairers' must be granted free access to appropriate repair instructions by the manufacturer.

The European Parliament has set the 'right to repair' as a priority for 2022. This will create new business areas and reactivate old ones: Repair shops for 'white' and 'brown' goods, which will then once again have the conditions to repair electrical appliances professionally. Replacing components on the circuit board will once again be considered more sensible than replacing an entire electronic unit.

A rethink is also underway in module production

Despite the high degree of automation, re-soldering work is unavoidable in electronic assembly production with the lowest error rates. Typical errors include unintentional solder bridges, non-soldering and displaced or missing components. Electronically defective components are only detected after the soldering process, e.g. in the in-circuit test, and must be replaced. Another reason for manual soldering is components that cannot be soldered automatically due to their design, the layout of the PCB or simply for economic reasons.

The right choice of solder and flux is just as important for manual soldering as it is for machine soldering. Depending on the requirements, solder wires with flux cores (tubular solders), solder pastes with and without metal powder content or repair fluxes in combination with (mini) dip solder baths can be used. In the following, we will deal with the selection of suitable soldering agents.

Tubular solders

Tubular solders (soft solder wires with flux filling) are available in various metallic alloys and flux types in various diameters.

When selecting the right solder wire, the user is faced with the following basic questions:

- Which alloy should be used (leaded/lead-free)?

- Which type of flux is appropriate for the application?

- What proportion of flux is required?

- Which solder wire diameter is suitable?

Selection of the soft solder alloy

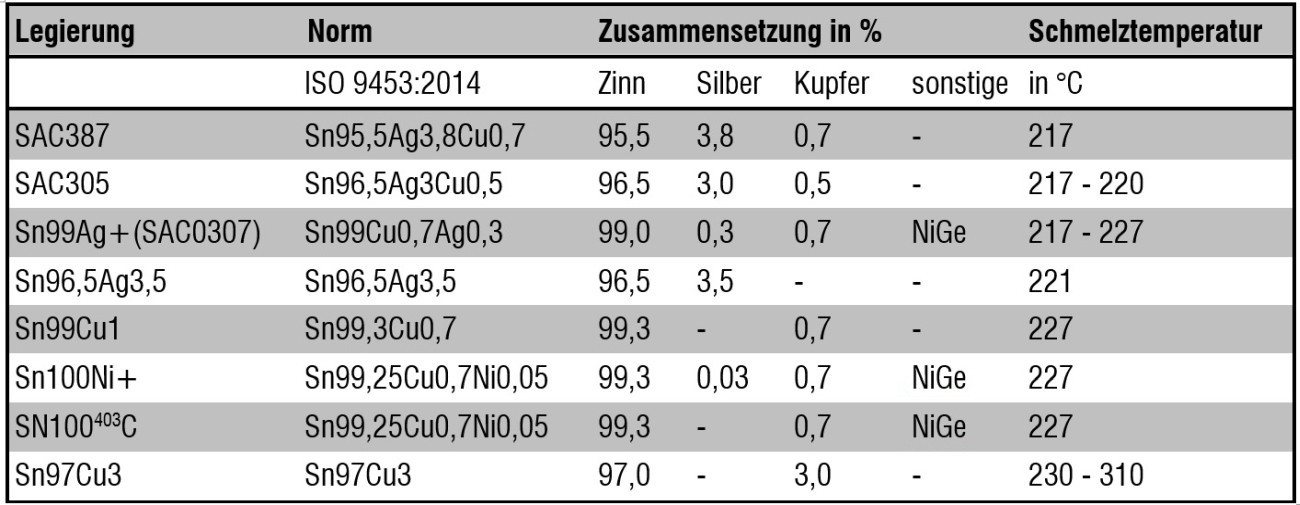

RoHS-compliant assemblies must, with a few exceptions, be soldered lead-free. Of course, this also applies to soldering work required for repairs. The common lead-free alloys for the hand soldering process are the same as those for wave and reflow soldering processes.

The soft solders used in component production are listed in the ISO 9453 standard, among others. Parts 1 to 3 of DIN EN 61190-1-3 also describe the requirements for joining materials for electronic assemblies.

So now you are spoiled for choice. It certainly makes sense to use the solder alloy that was used in the upstream soldering process. So Sn100Ni+, as in the wave? But SAC387 or SAC405 was used in the reflow process! Does the solder wire now have to be changed from solder joint to solder joint? Or is it safe to mix lead-free solders, for example to re-solder a SAC305 solder joint with Sn99.3Cu0.7?

Tab. 1: Common lead-free solder alloysThisis of course primarily dependent on internal and external specifications of your production, such as IPC J-STD-001 (requirements for soldered electrical and electronic assemblies). But what exactly is produced when tin-copper and tin-silver-copper are mixed? That's right, tin-silver-copper. "Not a clearly defined state" you are now rightly saying. But the solder from the wave or the reflow process is no longer present on the PCB in the defined original composition after these soldering processes at the latest! Depending on the PCB finish, you have already 'contaminated' the solder alloy to a greater or lesser extent with tin-copper-nickel (HAL lead-free), nickel-gold (ENIG), silver (chem. Ag) or copper (OSP).

Tab. 1: Common lead-free solder alloysThisis of course primarily dependent on internal and external specifications of your production, such as IPC J-STD-001 (requirements for soldered electrical and electronic assemblies). But what exactly is produced when tin-copper and tin-silver-copper are mixed? That's right, tin-silver-copper. "Not a clearly defined state" you are now rightly saying. But the solder from the wave or the reflow process is no longer present on the PCB in the defined original composition after these soldering processes at the latest! Depending on the PCB finish, you have already 'contaminated' the solder alloy to a greater or lesser extent with tin-copper-nickel (HAL lead-free), nickel-gold (ENIG), silver (chem. Ag) or copper (OSP).

Or you can opt for the solder with the lowest melting temperature (SAC387) to protect the assembly and soldering iron. If we look at the recommendations of soldering station manufacturers, a soldering iron temperature of 350-380 °C is recommended for lead-free solder (regardless of the solder alloy). Due to their composition and the higher soldering temperatures required, lead-free solders are considerably more aggressive towards common base materials and system components in electronics production. This also means that soldering tips are deposited more quickly and, in the worst case, become unusable within a few days! In addition to the standard solder alloys, solders with so-called micro-doping are therefore preferred since the changeover from lead-free. These dopings are alloy additives such as nickel, germanium etc.. Nickel in particular serves to protect the soldering tips and significantly extends their service life. The removal of the substrate metallization is also significantly lower in low-silver or silver-free solder alloys with nickel doping. Alloys such as Sn100Ni+, SN100403C or Sn99Ag+ are therefore ideally suited for re-soldering despite their higher melting point.

Selection of the flux

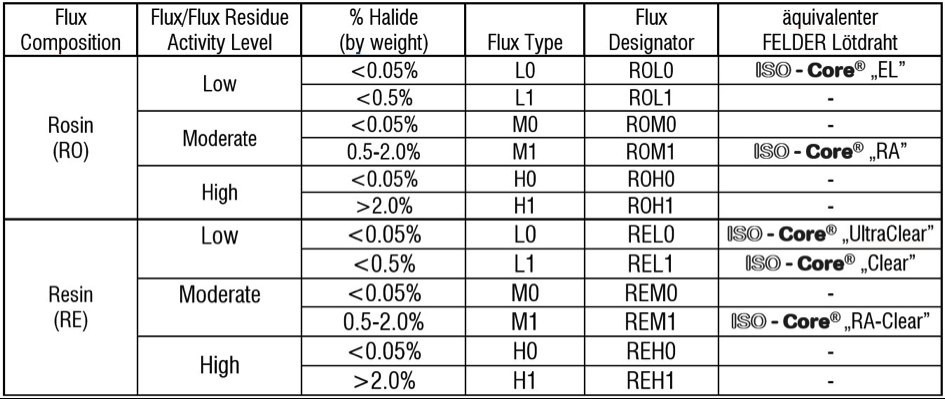

In principle, all fluxes of the same type (but from different manufacturers) can be mixed with each other. The flux used for reworking must be compatible with the fluxes used in the automatic soldering processes. In assembly production, fluxes classified as ROL0, ROL1, REL0 or REL1 are mainly used. These are halogen-free or low-halogen activated fluxes based on natural (RO) or synthetic (RE) resins, the residues of which are referred to as 'no-clean'.

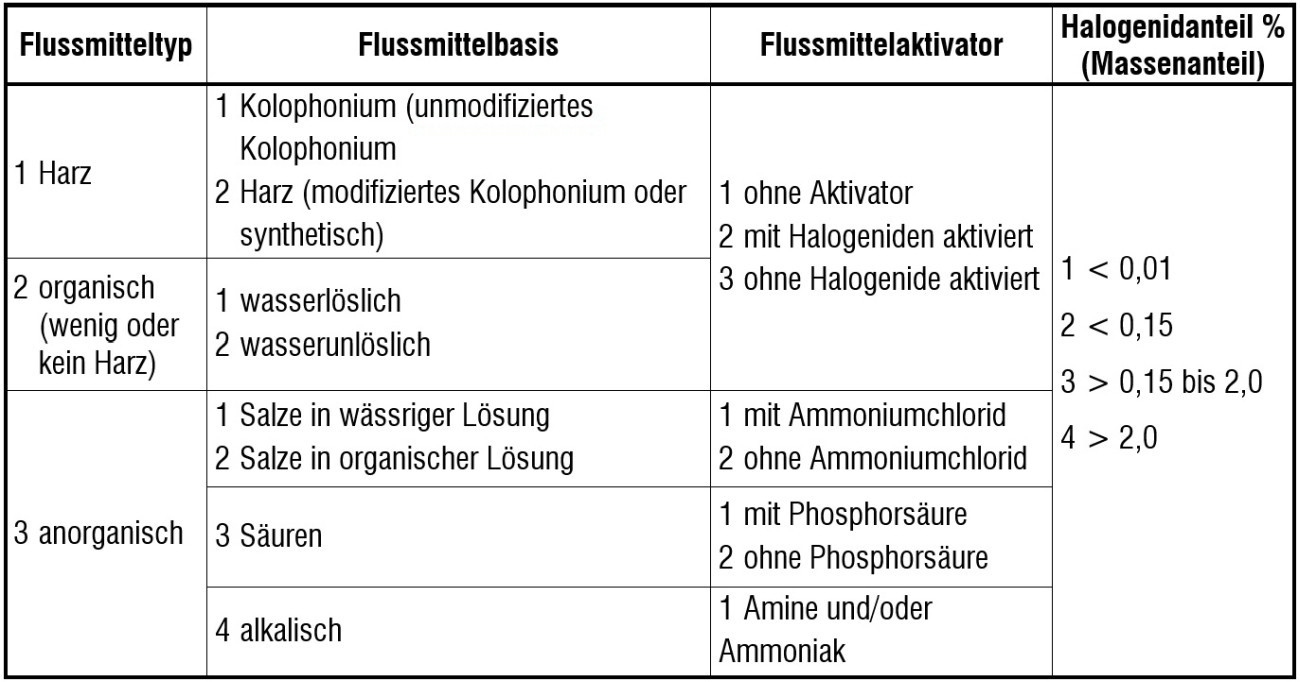

In addition to the internationally recognized IPC standard, ISO 9454.1 is another standard for soft soldering fluxes, but it is not exclusively concerned with the application area of electronics production (see Table 3). Another significant difference between the two standards lies in the classification. While IPC-J-STD-006 classifies the fluxes according to their activation or the effect of the flux residues, ISO 9454-1 is based on the main components of the flux.

Tab. 2: Extract from IPC J-STD-006 with the equivalent FELDER solder wire types

Tab. 2: Extract from IPC J-STD-006 with the equivalent FELDER solder wire types

Tab. 3: Classification of soft soldering fluxes according to their components (ISO 9454.1)Fluxes with higher halide contents > 0.5 % have hardly been used in component production to date due to the risk of corrosion of their residues and the lower insulation resistances. Through continuous, intensive research in the soldering flux sector, Felder has succeeded in developing a solder wire that combines the excellent soldering properties of a halogen-activated solder wire with the no-clean functionality of ROL0 or REL0 fluxes using a balanced mixture of organic acids, high-quality resins and halides.

Tab. 3: Classification of soft soldering fluxes according to their components (ISO 9454.1)Fluxes with higher halide contents > 0.5 % have hardly been used in component production to date due to the risk of corrosion of their residues and the lower insulation resistances. Through continuous, intensive research in the soldering flux sector, Felder has succeeded in developing a solder wire that combines the excellent soldering properties of a halogen-activated solder wire with the no-clean functionality of ROL0 or REL0 fluxes using a balanced mixture of organic acids, high-quality resins and halides.

The lead-free Felder solder wire ISO-Core 'Clear' was subjected to all standard tests in accordance with IPC-TM-650:

|

2.3.32 |

Copper mirror test |

passed |

|

2.4.46 |

Spread test |

passed |

|

2.4.48 |

Test for flux splashes |

passed |

|

2.6.3.3 |

Surface resistance test |

> 100 MΩ |

|

2.6.14.1 |

Test for electrochemical migration |

passed |

|

2.6.15 |

Test for corrosivity |

passed |

Required flux content

Common flux contents are: 1.0, 1.5, 2.0, 2.2, 2.5, 3.0 and 3.5 %. Halogen-free tubular solders are usually offered with a flux content of 3 to 3.5 %, while those containing halogens tend to be offered with 2.2 to 2.5 %. Solder wires with a lower flux content (0.7-1.5 %) can also be used for reworking and repairing solder joints from the wave or reflow process, as usable flux residues from previous soldering processes are present on the assembly. The flux is located inside the wire, in the so-called flux core. In multicore solder wires, the flux is divided into 3 to 5 chambers. This is intended to transport the flux to the soldering point more quickly and ensure a constant flux content in the wire.

Optimum wire diameter

Fig. 1: Schematic representation of single and multi-segmented solder wiresThechoice of the appropriate wire diameter depends on the required solder volume of the solder joint and therefore also on the component size. With the advancing miniaturization in electronics production, solder wires with finer diameters are also required. Whereas in the 1990s, solder wire with a diameter of 1.0 to 1.5 mm could be found at every rework workstation, today diameters of 0.5 to 1.0 mm are the rule. Common wire diameters are

Fig. 1: Schematic representation of single and multi-segmented solder wiresThechoice of the appropriate wire diameter depends on the required solder volume of the solder joint and therefore also on the component size. With the advancing miniaturization in electronics production, solder wires with finer diameters are also required. Whereas in the 1990s, solder wire with a diameter of 1.0 to 1.5 mm could be found at every rework workstation, today diameters of 0.5 to 1.0 mm are the rule. Common wire diameters are

- for SMD components: 0.15-0.5 mm

- for THT components: 0.5-1.0 mm

- Cable assembly: 0.75-1.5 mm

The right soldering iron tip should also be selected for the wire thickness and component dimensions. Everything is available, from a fine pencil tip to a width of 20 mm! However, if the tip is too small, the soldering time will be longer - this is not economical. If it is too large, it obstructs the view of the solder joint or even heats neighboring contacts.

SMD solder pastes

SMD solder pastes are the result of the professional evaluation of requirements in the application and the assessment of collected customer requests for their feasibility. SMD solder pastes are used not only for serial assembly production but also for repair work, especially on high-quality components.

When replacing BGAs or LEDs, pressure or dosable SMD pastes are increasingly being used to avoid thermal overloading of the components.

Fig. 2 and 3: Replacement of BGAs and rework on temperature-sensitive SMD LEDs

If the soldering process is viewed solely from the perspective of the solder manufacturer, wetting and spreading are significantly influenced by the resins, activators and solder alloy used in the metal powder of an SMD solder paste.

Flux

SMD solder pastes based on natural resins(Fig. 4) leave more or less dark residues on the assemblies. Even color variations between different batches of a paste type are not uncommon. The synthetic resins used in the 'Clear' soldering agents are water-clear, color-constant and thermally stable(Fig. 5). The inconspicuousness of flux residues plays a particularly important role in repairs and soldering rework.

Fig. 5: Whether a repair flux is synthetic or based on natural resins can be easily recognized by its color: natural resins are mostly amber-coloured, synthetic resins are colourless

Fig. 5: Whether a repair flux is synthetic or based on natural resins can be easily recognized by its color: natural resins are mostly amber-coloured, synthetic resins are colourless

Viscosity

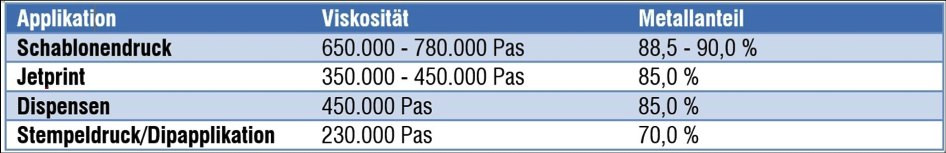

SMD solder pastes for rework and repair are mainly processed in dispenser cartridges, as a printing process on an already assembled module is rarely feasible. To ensure that the paste can be dispensed, it has a lower viscosity and a lower metal content than pastes for stencil printing.

Tab. 5: Applications and viscosities using the example of ISO-Cream 'Clear' paste

Tab. 5: Applications and viscosities using the example of ISO-Cream 'Clear' paste

Metal powder

When selecting the correct metal powder content of an SMD paste, this should correspond to the alloy used in the upstream processes. However, if nearby solder joints are not to be melted as well, a low-melting solder alloy such as Bi58Sn42 (melting point 138 °C) is recommended.

When selecting the grain size for printable SMD solder pastes, the particle size of the metal powder should match the component size and the dispensing needle used.

SMD and BGA repair fluxes

To match the lead-free SMD solder paste ISO-Cream 'Clear', the user can also choose a repair flux ISO-Flux 'Clear' with the same attributes. The formulation is based on synthetic resins, does not contain rosin [1] and is tailored to the requirements of lead-free soldering technology:

- high wetting speed and spread on all surfaces commonly used in electronics

- crystal-clear flux residues to optimize the visual impression

- low outgassing and neutral odor reduces workplace pollution

- easily removable flux residues, which can be removed without residue using all conventional cleaning agents.

The SIR-100 MΩ, copper level and corrosion tests in accordance with IEC 61189-5 and 61189-6 and IPC J-STD-004B were passed. The fluxes can therefore be used without restriction in assembly production.

Summary

In order to meet the ecological demands of consumers for sustainable and holistic consumer electronics, manufacturers of soldering products also have a duty. The aim is to find and implement approaches for production that is asCO2-neutral and sustainable as possible. Felder is pursuing several approaches and uses raw materials from fair sources and electricity from 100% renewable energy sources (including for melting processes), uses waste heat from machines and ovens as well as process water to reduce fresh water, recycles old metals and flux, uses recycled plastics for wire coils, paste and flux cans, is gradually converting the company fleet to vehicles with hybrid and electric drives and offers its employees and their families a bicycle leasing program.

As this article shows, sustainable tools and filler materials should be used when repairing devices that fall under the Eco-Design Directive. For example, all the soldering agents listed here are produced in Germany for the European market. This is a further step on the way to the smallest possibleCO2 footprint.

About the person

About the person

Udo Grimmer-Herklotz has been responsible for technical customer support in Felder's application technology department since 1999 and has extensive knowledge of soldering processes in electronic assembly and PCB production.

References

[1] The rosin once used for soldering work in electronics production is considered harmful to health and often causes allergic reactions, asthma and eczema. Cf.: www.biologie-seite.de/Biologie/Kolophonium