After the successful technology forum with in-house exhibition last fall, Ersa GmbH took the plunge again in June and held a second face-to-face event of this kind despite the coronavirus pandemic.

A particular attraction of the exhibition was the Kurtz Ersa Alpha 140 3D printerWitharound 200 participants and some new products, it was worthwhile again. And there was general delight that after so many (home office) months, a face-to-face meeting with direct communication and product inspection was possible again.

A particular attraction of the exhibition was the Kurtz Ersa Alpha 140 3D printerWitharound 200 participants and some new products, it was worthwhile again. And there was general delight that after so many (home office) months, a face-to-face meeting with direct communication and product inspection was possible again.

The three-day event provided information on current trends in electronics production, focusing on process areas ranging from stencil printing, reflow, selective and wave soldering to automated rework and hand soldering, supplemented by Industry 4.0, automation and metallic 3D printing. In addition to presentations, there were live demonstrations of current electronics production systems and automation solutions as well as the opportunity for extensive dialog with experts from Ersa and partner companies. In addition to Ersa, the partner companies ASM SMT Solutions, Christian Koenen, GlobalPoint, Inmatec, Interflux, Klepp Absauganlagen, Kraus Hardware, Kolb Cleaning Technology, KSG, Kurtz and Viscom took part in the in-house exhibition.

Exemplary safety concept

In order to offer everyone the best possible safety, Ersa expanded the hygiene concept that had already proven itself at the first event - there had been no Covid infections - to include a complete test line with Covid-19 PoC antigen tests. Everyone had to be tested daily in order to gain access with a different colored wristband and mask each day. In addition, the number of participants has been equalized by repeating the technology presentations of the first day on the third day.

Global. Ahead. Sustainable - Ersa's strategy

As part of the introduction, Rainer Krauss, General Sales Manager at Ersa, and Hansjürgen Bolg, Business Unit Manager Tools, Rework & Inspection, addressed the strategy "GLOBAL. AHEAD. SUSTAINABLE." strategy, according to which Ersa and the other companies of the Kurtz Ersa Group implement advanced, holistic solutions and services sustainably and efficiently as well as globally through their own subsidiaries or via partner companies. Ersa's centenary this year is proof of the sustainability it has practiced for years. After all, Ersa understands 'sustainable' to mean much more than just green. Accordingly, sustainable solutions for the future were also presented in the lectures, exhibits and live demonstrations.

Sustainable solutions presented in lectures, exhibition and live demonstrations

According to Rainer Krauss, automation is generally necessary today, with robotics and testing in the foreground and customer-specific solutions in demand. What the Kurtz Ersa Group offers in this respect for the entire industry and specifically for electronics production was demonstrated in the first presentation by him together with Marcel Buck, Product Manager Optical Control at Ersa GmbH.

Using application examples and best practice solutions, they explained all the "Automation: Key solutions for your THT electronics production" offered by Kurtz Ersa. Marcel Buck presented the Versaguide product in detail. It is a modular optical system that supports the manual assembly process and can be used both inline and standalone. The worker receives feedback as to whether the assembly is correct or not before the electronics are transported on to soldering. For this purpose, Versaguide uses a high-resolution camera to check the product in progress based on the BOM (programming). Among other things, the polarities are checked and the codes are read in (with direct transmission via Ersa Code Pipeline) so that the process can be interlocked if necessary, thus reducing rework and rejects. The system is characterized by its large working distance, its large illumination panel for stable conditions and its large field of view (designed for solder frames). It can also be upgraded at any time and has a convenient graphical user interface. The I/O module enables process tracking.

Stefan ZechNicolasBartschat, Product Manager Industry 4.0 at Ersa GmbH, then explained what "Industry 4.0: Ready for the digital future" means with Kurtz Ersa Connect. Existing processes are to be improved and expanded in order to increase service quality, improve the process quality of Kurtz Ersa systems and create more transparency in the production process. As a solution, a secure connectivity of the machines was developed using gateway architecture, whereby the implementation of security issues was carried out with a strong partner (Microsoft Azure) and Kurtz Ersa Connect was created as a central modular platform. Applications have already been implemented on this basis: a digital life cycle of the machines with Machines, an intelligent ticket system with Tickets and a tool for knowledge transfer with E-Learning. Nicolas Bartschat explained the details and then explained the advantages of the gateway solution from Kurtz Ersa. It is the same for all machines and has standard interfaces to other systems. It is designed as a central platform and secure technical prerequisite as the basis for all future digital solutions and thus the basis for optimizations in the areas of service, process and production. It also offers worldwide update capability as well as upward and downward compatibility, worldwide remote support and future-proofing.

Stefan ZechNicolasBartschat, Product Manager Industry 4.0 at Ersa GmbH, then explained what "Industry 4.0: Ready for the digital future" means with Kurtz Ersa Connect. Existing processes are to be improved and expanded in order to increase service quality, improve the process quality of Kurtz Ersa systems and create more transparency in the production process. As a solution, a secure connectivity of the machines was developed using gateway architecture, whereby the implementation of security issues was carried out with a strong partner (Microsoft Azure) and Kurtz Ersa Connect was created as a central modular platform. Applications have already been implemented on this basis: a digital life cycle of the machines with Machines, an intelligent ticket system with Tickets and a tool for knowledge transfer with E-Learning. Nicolas Bartschat explained the details and then explained the advantages of the gateway solution from Kurtz Ersa. It is the same for all machines and has standard interfaces to other systems. It is designed as a central platform and secure technical prerequisite as the basis for all future digital solutions and thus the basis for optimizations in the areas of service, process and production. It also offers worldwide update capability as well as upward and downward compatibility, worldwide remote support and future-proofing.

Partner companies presented lectures and products

With the increasing miniaturization of components, the risk of errors caused by PCB tolerances is also increasing. Michael Zahn, Christian Koenen GmbH, looked at the influence of the PCB on stencil printing in the fine pitch area. For example, vias that are covered relatively high by the solder mask, over-etched pads, differently sized mounting surfaces of a component and/or warpage of the PCB can lead to lean solder joints and/or offset solder deposits. This is because the solder paste printing stencil rests on (the) raised areas so that the paste may not come into contact with the neighboring copper pads during printing and therefore does not (completely) detach from the apertures of the stencil, as the adhesive surface (force) of the pads is not sufficient to pull the paste completely out of the apertures. However, the error rate can often be drastically reduced by adapting the stencil design for such PCBs. Michael Zahn explained what is possible here. He used examples, including a bad/good comparison, to illustrate how treating the underside of the stencil with plasma affects the release behavior.

Dawid Ziebura from Laser Melting Innovations GmbH & Co. KG provided information on additive manufacturing - the potential of metallic 3D printing using LPBF (Laser Powder Bed Fusion). The LPBF process is carried out layer by layer: A first layer of metal powder is applied to a lowerable platform. A laser beam is used to melt and solidify the powder locally according to the desired product structure. The platform is lowered further and another layer of metal powder is applied and structured using a laser. This is repeated until the desired product is completely built up. The machine program for the layered structure, including the required support elements, is generated from the STL file (CAD data). This is followed by post-processing, which gives the additively manufactured product its final shape (removal of support elements) and properties. As illustrated by examples, products with a wide variety of geometries, including cavities and overhanging parts, can be created for a wide range of industries and operating conditions. The LPBF process is characterized not only by the significantly expanded possibilities for product design, but also by the fact that design changes and very small quantities (quantity 1) are possible without any problems and without major effort. The Alpha 140 system developed by Laser Melting Innovations for the LPBF process is now being produced in series by Kurtz GmbH and sold worldwide. This cooperation was launched a year ago.

Six experts were present at the panel discussion and the others joined in digitally

Six experts were present at the panel discussion and the others joined in digitally

In his presentation 'Cleaning - a curse or a blessing?', Bert Schopmans, Kolb Cleaning Technology GmbH, began by listing the cleaning requirements in the electronics industry - in addition to products, tools etc. also need to be cleaned. He then explained why the term 'no clean' is outdated: After soldering, oxides and flux residues can also be found outside the solder pads, which can result in risks such as leakage currents due to environmental influences, which was illustrated using fault images and a video of electronic assemblies that had not been cleaned. Climate-proof assemblies can be produced by cleaning, which is required by a number of industries and applications. In addition, protection must be applied to sophisticated products, for which cleaning in advance also makes sense. Bert Schopmans also went into the inspection options for cleanliness/residual contamination as well as details and options for tool cleaning. The bottom line is that cleaning is not a value-adding process, but a quality-creating one, as it contributes to the reliability of the product.

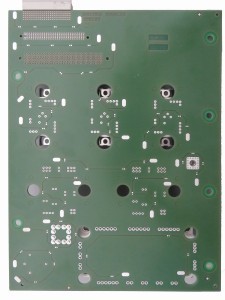

Press-Fit demonstrator (top and bottom)

Stefan Zech, Inmatec Gase Technologie GmbH & Co KG, demonstrated that modern nitrogen systems 5.0 enable process costs to be reduced by up to 90 %. He also listed other advantages associated with the self-generation of nitrogen. After all, sustainable production requires a new perspective on environmental protection and economic efficiency. For example, on-site production requires fewer truck transports, which reducesCO2 and particulate pollution and relieves road traffic. CO2 savings of 90 % compared to liquid nitrogen supply are possible. Operating costs can also be reduced by 90 %. There is also the option of heat recovery, as 96% of the electrical energy used is lost as waste heat. This can be used for heating processes and rooms as well as for air conditioning, for which BAFA funding is available. Stefan Zech concluded by explaining the NKAT system concept, which uses innovative hydrogen technology to produce 99.999% N2 (nitrogen 5.0) economically and cost-effectively (from 1 cent/m3) from compressed air.

Press-fit technology forum - first panel discussion at Ersa was well received

The panel discussion on press-fit technology took a look outside the box. Ersa organized a panel discussion for the first time with the Press-fit Technology Forum - Expert Meeting and Exchange of Experience. Moderated by Ersa, six present and other digitally connected participants discussed the why/why and how. Until now, press-fit technology in PCB technology has tended to be a niche technology with limited areas of application. Press-fit technology is now increasingly being used for high-current applications and normal connectors. Components suitable or designed for press-fitting are available. The higher tolerance requirements for PCBs are no longer a problem. However, the process must still be closely monitored (press-in/press-out force according to the component manufacturer's specifications). The control extends to X-ray inspection. A working group is currently developing a guideline for press-fit technology. A press-fit demonstrator from the working group already exists and could be inspected after the panel discussion.

"After many months of social distancing, the Technology Forum finally made it possible to experience the feeling of being together again ..."

An all-round successful event

The participants not only praised the good organization and the exemplary hygiene concept. They were also delighted that a face-to-face meeting could finally take place again. "After many months of social distancing, the Technology Forum finally made it possible to experience the feeling of togetherness that is so important for industries such as electronics manufacturing," emphasized Ersa CEO Ralph Knecht.

The best weather and the supporting program with a visit to the Kurtz Ersa hammer mill in Hasloch and an evening barbecue on the roof terrace with live jazz music put the icing on the cake. "These were three great days, during which we presented the latest innovations for electronics production to customers and interested parties in collaboration with our partners - we'll definitely be doing this again soon," said Rainer Krauss at the end of the Technology Forum.