The latest event in the EMIL (Electronic Manufacturing + Inspection Solutions) series attracted numerous visitors, and not just because of the special ambience. The production technologies of the future presented there in lectures and live demonstrations were met with great interest.

The event was opened by Andreas M. Keiner (nemotronic) with the official welcome and a short introduction, followed by the first block of presentations.

Optimization opportunities that should be exploited

Olaf Römer (ATEcare Service) began with a quote from AUDI board member Hildegard Wortmann: 'There is a 50% chance that Audi will still be around in ten years' time. - If we don't take advantage of change, our prosperity will crumble!' He then listed many sources that say that Germany is too slow. He then posed the question: "Are we standing in our own way?" The outlook for the electronics industry is good despite the enormous challenges. There are many opportunities for optimization that just need to be exploited. Olaf Römer gave examples of how test coverage, throughput, costs and IT connections can be optimized and how a smart material flow or complete automation of merchandise management can be implemented. He presented several products in detail, including

- the smart inspection robotics CAD2SCAN from Kitov

- elements of fully automated warehouse solutions (including software from abp, automatic component counters and autonomous transport systems)

- new 3D AOI and AXI solutions from Omron, including MPS (Micro Phase Shifting) for automatic shadow and reflex compensation

- Salvador's new Air Gap technology, with which the system is back on course within 30s after cyber attacks

Summary of boundary scan test, functional control and programming

Alexander Beck (Göpel electronic) explained how testing without a point or an ATE on board can be realized with Embedded JTAG. Based on the possibilities of the various electrical test methods for electronic assemblies and the boundary scan principle, he listed the faults that can be detected with boundary scan: Short circuits, interruptions and incorrect or missing components. External access also makes it possible to increase fault coverage. He then went into the embedded JTAG test procedure, in which testing and programming are carried out via a communication port (also accessed via SWD, SBW, PIC, I2C, SPI etc.) and internal processor functions are also used. Embedded JTAG is a combination of boundary scan, functional control and programming. Alexander Beck listed the instruments and products (from Scanflex components to turnkey solutions for production) that Göpel electronic offers for this and illustrated the possibilities using application examples.

New test solutions for battery production

Henrik BrüggingAbout'Gasoline in your blood! How do we meet the challenges of modern electromobility/battery production', Henrik Brügging (Seica Germany) spoke, starting with a look back at the history of the automobile. The first cars were electrically powered. Until 1920, they were a competitor to combustion engines. Today there are around 47 million cars in Germany. The average daily consumption of an electric car can be charged in 3 hours via a normal earthed socket. The additional power required for this can easily be created through expansion, as it will take at least 20 years for this to be fully utilized with the current increase in e-vehicles, as the average vehicle service life is correspondingly long. However, the increasing battery production for e-cars is creating a huge waste problem. This is because the gigafactories consume a lot of energy and material for cells, which are disposed of as waste due to a lack of or inadequate process controls. This is where Seica comes in as an innovative company that has been offering test solutions for the electrical units of vehicles for some time and has now expanded these to include e-vehicles and, with the new Pilot BT Line, solutions for testing batteries. Henrik Brügging explained the features of this new test system as well as the Compact BMS Line and the universally applicable Pilot VX Next series.

Henrik BrüggingAbout'Gasoline in your blood! How do we meet the challenges of modern electromobility/battery production', Henrik Brügging (Seica Germany) spoke, starting with a look back at the history of the automobile. The first cars were electrically powered. Until 1920, they were a competitor to combustion engines. Today there are around 47 million cars in Germany. The average daily consumption of an electric car can be charged in 3 hours via a normal earthed socket. The additional power required for this can easily be created through expansion, as it will take at least 20 years for this to be fully utilized with the current increase in e-vehicles, as the average vehicle service life is correspondingly long. However, the increasing battery production for e-cars is creating a huge waste problem. This is because the gigafactories consume a lot of energy and material for cells, which are disposed of as waste due to a lack of or inadequate process controls. This is where Seica comes in as an innovative company that has been offering test solutions for the electrical units of vehicles for some time and has now expanded these to include e-vehicles and, with the new Pilot BT Line, solutions for testing batteries. Henrik Brügging explained the features of this new test system as well as the Compact BMS Line and the universally applicable Pilot VX Next series.

All-in-one system for assembly and high-tech dispensing

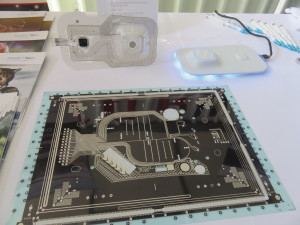

Jürg Schüpbach (Essemtec) then presented the solutions for smart electronics production that his company has in its portfolio under the title 'The Archer Fish or All in One Process Technologies for Printed Electronics'. Prior to this, he discussed the development of PCB technology towards circuits printed on films and IMSE technology (Injection Molded Structural Electronics). The latter has many advantages, including in particular fewer parts and a significantly lowerCO2 footprint. Jürg Schüpbach listed what is required for the assembly process of such circuits: a combination of assembly and high-tech dispensing, i.e. jetting of conductive adhesive (dots of 250 µm), jetting of solder paste (dots of 260 µm), jetting of structural adhesive and film management with vacuum stations. This is made possible with the all-in-one system on a single platform from Essemtec. And the DragonFly from NanoDimension already offers a solution for the upcoming AME (Additively Manufacturing Electronic), in which the product is realized in a single production step based on the CAD data.

The live demonstrations started after the break.

WithCO2 upcycling to renewable energy sources

Luca SchmidlinThesecond lecture block began with a presentation by Luca Schmidlin (AlphaSynt). Under the title 'Powered to X and the contribution to security of supply', he provided information on the new technological possibilities and emphasized: "The energy transition is taking place in the present!" Renewable energy sources can be obtained throughCO2 upcycling. As these areCO2-neutral, they can make a contribution to achieving climate protection targets. They are also easy to transport and (seasonally) store, and existing infrastructures can be used. Their local production increases security of supply. Further advantages are that the technology can be implemented quickly and is easily scalable. Sector coupling (electricity and gas grids) also increases the flexibility of the energy grids. The large amounts of electricity that are lost due to the regulated shutdown of wind turbines in particular could be used to generate green hydrogen and produce eFuel or SynFuel. Luca Schmidlin also provided information on the HYFUELUP project, which aims to demonstrate an innovative approach to large-scale biomethane production based on the integration of sorption-assisted gasification, methanation via a catalytic fluidized bed and high-temperature electrolysis. The energy of 1m³ of synthetic CH4 corresponds approximately to that of 1l of gasoline, i.e. approx. 10kWh.

Luca SchmidlinThesecond lecture block began with a presentation by Luca Schmidlin (AlphaSynt). Under the title 'Powered to X and the contribution to security of supply', he provided information on the new technological possibilities and emphasized: "The energy transition is taking place in the present!" Renewable energy sources can be obtained throughCO2 upcycling. As these areCO2-neutral, they can make a contribution to achieving climate protection targets. They are also easy to transport and (seasonally) store, and existing infrastructures can be used. Their local production increases security of supply. Further advantages are that the technology can be implemented quickly and is easily scalable. Sector coupling (electricity and gas grids) also increases the flexibility of the energy grids. The large amounts of electricity that are lost due to the regulated shutdown of wind turbines in particular could be used to generate green hydrogen and produce eFuel or SynFuel. Luca Schmidlin also provided information on the HYFUELUP project, which aims to demonstrate an innovative approach to large-scale biomethane production based on the integration of sorption-assisted gasification, methanation via a catalytic fluidized bed and high-temperature electrolysis. The energy of 1m³ of synthetic CH4 corresponds approximately to that of 1l of gasoline, i.e. approx. 10kWh.

Vapor phase reflow technology with vacuum

Olaf CieplyOlafCieply (IBL-Löttechnik) demonstratedthatvapor phase reflow technology can be used for cost-efficient, environmentally friendly and void-free soldering. He explained the development of vapor phase soldering and his company. He then went into the physics of the process and the realization of the system technology. The focus was on the patented Soft Vapour Phase process for precise and efficient control of the thermal energy by vertically changing the position of the soldering material within the saturated vapour blanket and the likewise patented In Vapour Vacuum technology, in which evacuation takes place directly in the soldering zone in the vapour phase area, which has many advantages (completely oxygen-free process, no loss of time or product temperature, optimum pore reduction). Olaf Cieply described the various IBL systems as well as their design and features.

Olaf CieplyOlafCieply (IBL-Löttechnik) demonstratedthatvapor phase reflow technology can be used for cost-efficient, environmentally friendly and void-free soldering. He explained the development of vapor phase soldering and his company. He then went into the physics of the process and the realization of the system technology. The focus was on the patented Soft Vapour Phase process for precise and efficient control of the thermal energy by vertically changing the position of the soldering material within the saturated vapour blanket and the likewise patented In Vapour Vacuum technology, in which evacuation takes place directly in the soldering zone in the vapour phase area, which has many advantages (completely oxygen-free process, no loss of time or product temperature, optimum pore reduction). Olaf Cieply described the various IBL systems as well as their design and features.

SMD assembly away from the PCB

Dr. Jörg NiemeierDr. Jörg Niemeier (ATN Automatisierungstechnik Niemeier) spoke on the topic of 'SMT with a difference: selective SMD assembly away from the PCB'. His company offers solutions for product-specific SMD assembly on alternative substrates to rigid PCBs. These include dispensing equipment and soldering robots as well as process automation. He illustrated this with video examples. For the production of textile electronics, for example, the soldering system including jet valve can be integrated into the 'fabric show' of the textile production system. The integration of soldering, dosing and other units is possible in almost all production systems, so that specific complete assembly systems including AOI can be realized. Dr. Jörg Niemeier described the units on offer, which range all the way up to standard platforms. This means that roll-to-roll solutions for films can also be realized.

Dr. Jörg NiemeierDr. Jörg Niemeier (ATN Automatisierungstechnik Niemeier) spoke on the topic of 'SMT with a difference: selective SMD assembly away from the PCB'. His company offers solutions for product-specific SMD assembly on alternative substrates to rigid PCBs. These include dispensing equipment and soldering robots as well as process automation. He illustrated this with video examples. For the production of textile electronics, for example, the soldering system including jet valve can be integrated into the 'fabric show' of the textile production system. The integration of soldering, dosing and other units is possible in almost all production systems, so that specific complete assembly systems including AOI can be realized. Dr. Jörg Niemeier described the units on offer, which range all the way up to standard platforms. This means that roll-to-roll solutions for films can also be realized.

Sintering on organic base materials

After Dirk Buße (budatec) had compared the sintering and soldering processes, he showed that sintering on organic base materials is now possible. Sintered joints are stronger than soldered joints and remain so even at high temperatures (over 180°C). They also have greater thermal conductivity. This makes them interesting for many applications, especially in power electronics. Silver and copper sinter pastes are used as a substitute for high-melting solders. Their processability is acceptable. Improved materials are now also making applications on organic substrates interesting. The trend is towards the simultaneous sintering of chip, base plate and connecting strips as well as the use of copper pastes with lower process pressures and copper sintering under reducing atmospheres. With the SPM300, budatec offers a suitable sintering system.

Dipl.-Ing. Dirk Buße (budatec) presents the VS 160 vacuum soldering system

Dipl.-Ing. Dirk Buße (budatec) presents the VS 160 vacuum soldering system

Opportunities and risks of a small company

Thomas KieferThomasKiefer (Moteco) looked attheopportunities and risks of a small company in the electronics sector. The company belongs to G&C Germany. Two years ago, it took over the 'dismantled test adapters' division from Ingun Prüfmittel and is continuing this under the brand name Moteco following a repositioning. Opportunities are seen in the e-environment:

Thomas KieferThomasKiefer (Moteco) looked attheopportunities and risks of a small company in the electronics sector. The company belongs to G&C Germany. Two years ago, it took over the 'dismantled test adapters' division from Ingun Prüfmittel and is continuing this under the brand name Moteco following a repositioning. Opportunities are seen in the e-environment:

- Convince with shorter delivery times

- Adapt quickly to market situations

- Focus on value creation/service adapter expansion

- Overhead costs are adjusted

- Individual adaptation to customer needs

- Customers have a fixed contact person

Risks identified in the e-environment

- Dependent on partners for research and development

- Location near the Swiss border is a disadvantage

- Generalists and fewer specialists are needed

- Large companies treat small ones differently

- Capacity is limited

- Market changes are recognized later

- Company is noticed too late on the market

X-ray inspection: regulatory as well as technical requirements

In the last presentation, Michael Stoll (RXL Engineering GbR) provided information on simple implementation when choosing an X-ray inspection solution due to technical X-ray requirements. The focus is on the application. However, in addition to the technical requirements, regulatory requirements must also be met for X-ray inspection. These were explained, including the operational implementation. The materials to be inspected and the defects to be detected are decisive for the required properties of the X-ray system. In addition, the available time and the planned throughput must be taken into account in order to optimize the costs for the desired geometric and contrast resolution. A systematic step-by-step approach is recommended for the selection of the X-ray system.

Further live demonstrations followed after a break.

The event ended with a raffle and an open discussion round with the exhibitors.