The 80th meeting of the Saxon Electronics Technology Working Group (VDI/VDE) took place on March 29, 2023 at the Fraunhofer Institute for Ceramic Technologies and Systems IKTS in Dresden.

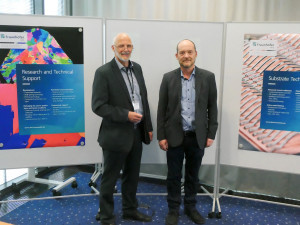

Prof. Bauer (left) and Dr. RebenklauDr.Lars Rebenklau (host from IKTS) and Prof. Reinhard Bauer (HTW Dresden and chairman of the working group) opened the meeting and were not only pleased about the numerous participants, but also particularly pleased that Prof. Sauer, the founder of the working group, and Prof. Wolter, co-initiator and supporter of the working group's activities, were able to attend. Both professors have now retired. Dr. Martin Oppermann (IAVT / ZµP at the TU Dresden) and Prof. Bauer have headed the working group since 2003.

Prof. Bauer (left) and Dr. RebenklauDr.Lars Rebenklau (host from IKTS) and Prof. Reinhard Bauer (HTW Dresden and chairman of the working group) opened the meeting and were not only pleased about the numerous participants, but also particularly pleased that Prof. Sauer, the founder of the working group, and Prof. Wolter, co-initiator and supporter of the working group's activities, were able to attend. Both professors have now retired. Dr. Martin Oppermann (IAVT / ZµP at the TU Dresden) and Prof. Bauer have headed the working group since 2003.

In a brief review of the development of the working group since 1994, and in particular the last ten meetings, Prof. Bauer paid tribute to the many years of involvement of many colleagues in the organization of the meetings.

The information about new developments and research results and the direct practical exchange of experience on site in production areas or laboratories were only possible thanks to the commitment of companies and research institutions, which provide both the space and the content for the meetings. Due to the coronavirus restrictions, the working group naturally also had to switch to online events. Prof. Bauer emphasized that many young colleagues have also supported the working group in recent years and that he is therefore very optimistic that the working group's concerns will continue to be of great interest. This was clearly demonstrated by the discussions and offers for the next meetings.

Participants of the 80th meeting of the Electronics Technology Working Group

Participants of the 80th meeting of the Electronics Technology Working Group

Hybrid microsystems

In a brief presentation of Fraunhofer IKTS, Dr. Lars Rebenklau, Group Manager System Integration and AVT, emphasized: "Hybrid microsystems are an important area of research at Fraunhofer IKTS". Several research groups are working on various aspects of thick-film technology along the entire value chain. The work focuses on the synthesis of materials as well as the development and modification of thick-film pastes and ceramic films. Other research topics include the use of thick-film materials, e.g. in ceramic heaters and sensors, as well as improved assembly and connection technology specifically for applications in harsh environmental conditions or for high-temperature applications up to 800 °C. The portfolio is complemented by a comprehensive characterization of developed components and modules through to the generation of service life data. The various research topics were presented in more detail in subsequent presentations.

Electrical functional layers on ceramic components

Dr. Claudia Feller reported on the development of special thick-film pastesIna second presentation, Dr. Rebenklau presented current work by the IKTS working group 'System Integration and AVT' on the development of functionalized additively manufactured ceramic system components. These components are manufactured in two steps: First, the components are additively manufactured on the basis of ceramic materials. After the components have been processed, including thermal treatment, they are functionalized using thick-film technology. Here, electrical functional layers, such as sensors or heaters for various applications, are printed and baked onto the ceramic components. This combination unites the advantages of additive manufacturing, such as highly complex geometries, with electrical functionalization. The resulting possibilities were illustrated using examples of highly dynamic ceramic heaters developed at Fraunhofer IKTS as part of an industry-led research project. Furthermore, techniques for contacting elements for higher operating temperatures of up to 600 °C were explained.

Dr. Claudia Feller reported on the development of special thick-film pastesIna second presentation, Dr. Rebenklau presented current work by the IKTS working group 'System Integration and AVT' on the development of functionalized additively manufactured ceramic system components. These components are manufactured in two steps: First, the components are additively manufactured on the basis of ceramic materials. After the components have been processed, including thermal treatment, they are functionalized using thick-film technology. Here, electrical functional layers, such as sensors or heaters for various applications, are printed and baked onto the ceramic components. This combination unites the advantages of additive manufacturing, such as highly complex geometries, with electrical functionalization. The resulting possibilities were illustrated using examples of highly dynamic ceramic heaters developed at Fraunhofer IKTS as part of an industry-led research project. Furthermore, techniques for contacting elements for higher operating temperatures of up to 600 °C were explained.

Dr. Claudia Feller, research associate in the IKTS working group 'Thick Film Technology and Functional Printing', presented current developments in thick film pastes for sensor technology, power electronics and high-frequency technology. Following introductory explanations of thick-film paste production, she focused in particular on newly developed photo-structurable thick-film pastes. These pastes are applied to corresponding substrates in the usual screen printing process and then structured using exposure and development steps. With this technique, geometrically very defined fineline structures can be realized especially for HF applications. Dr. Feller also went into detail about available material systems for different applications.

Fully digital layer-by-layer printing of up to four different materials

Roland Claus von Nordheim explains the advantages of digital heating systemsDr. Steffen Ziesche, Group Manager 'Microsystems, LTCC and HTCC' at Fraunhofer IKTS, presented development results from the established material systems HTCC (High-Temperature-Cofired-Ceramics) and LTCC (Low-Temperature-Cofired-Ceramics) as well as from the material system ULTCC (Ultra-Low-Temperature-Cofired-Ceramics) with sintering temperatures below 600 °C. The wide range of applications was illustrated by the components developed: highly miniaturized ceramic layer circuits with maximum wiring density, ceramic circuit carriers and antennas for high-frequency applications as well as 2.5D-structured ceramic carriers for sensor applications. The second part of the article dealt with novel processes for maskless, high-resolution 3D printing. The working group has a multi-material printer with integrated printing technologies (3x inkjet, 1x aerosol jet). This enables fully digital layer-by-layer printing of up to four different materials in combination with integrated inline layer forming/sintering. As example components, self-supporting ultra-thin ceramic membranes, printed NFC antennas and circuit carriers with highly miniaturized electrical vias were discussed. In addition, approaches to high-resolution printing on 3D geometries or in cavities were discussed.

Roland Claus von Nordheim explains the advantages of digital heating systemsDr. Steffen Ziesche, Group Manager 'Microsystems, LTCC and HTCC' at Fraunhofer IKTS, presented development results from the established material systems HTCC (High-Temperature-Cofired-Ceramics) and LTCC (Low-Temperature-Cofired-Ceramics) as well as from the material system ULTCC (Ultra-Low-Temperature-Cofired-Ceramics) with sintering temperatures below 600 °C. The wide range of applications was illustrated by the components developed: highly miniaturized ceramic layer circuits with maximum wiring density, ceramic circuit carriers and antennas for high-frequency applications as well as 2.5D-structured ceramic carriers for sensor applications. The second part of the article dealt with novel processes for maskless, high-resolution 3D printing. The working group has a multi-material printer with integrated printing technologies (3x inkjet, 1x aerosol jet). This enables fully digital layer-by-layer printing of up to four different materials in combination with integrated inline layer forming/sintering. As example components, self-supporting ultra-thin ceramic membranes, printed NFC antennas and circuit carriers with highly miniaturized electrical vias were discussed. In addition, approaches to high-resolution printing on 3D geometries or in cavities were discussed.

As a representative of a young company, Mr. Ronald Claus von Nordheim (Watttron in Freital) demonstrated the importance of temperature control in the processing of plastics and electronic components and how this can be implemented in new products with innovative developments. He explained the advantages of so-called digital heating systems based on ceramic thick-film technology. Using various examples, he demonstrated the potential of targeted heating of surfaces. With the help of Watttron's matrix heating technology, temperature fields can be generated that enable the forming of conductively printed and assembled films (see illustration of matrix heater with temperature field).

Ronald Claus von Nordheim also presented how digital heating systems can be used to enable inline diagnosis of the heating process, thus ensuring process stability can be monitored without additional measurement technology.

The presentations were met with lively technical discussion and the participants also used the breaks for personal technical discussions. Finally, all participants were able to see for themselves the excellent equipment and the very interesting research results on manufacturing technologies, system developments and characterization methods during demonstrations and practical discussions during a tour of the laboratory in various areas of IKTS.

Note: As this review is only now being published, we would also like to take this opportunity to congratulate Prof. Sauer on his 85th birthday, which he celebrated in August 2023. We wish him the best of health, happiness and well-being!