Product changeovers and other processes in EMS manufacturing can require manual intervention, slowing down SMT benefits and even causing line downtime. The following article from Yamaha shows that a combination of automation, greater efficiency and more flexibility can help.

Fig. 1: The RM high-speed rotary head extends the single-head concept and enables high-speed assembly of a wide range of componentsTiresomemanual operations associated with tasks such as product changeover can slow down SMD assembly and prolong production line downtime. A combination of advanced automation and features that increase efficiency and flexibility can significantly boost productivity. Human intervention is reduced to a minimum.

Fig. 1: The RM high-speed rotary head extends the single-head concept and enables high-speed assembly of a wide range of componentsTiresomemanual operations associated with tasks such as product changeover can slow down SMD assembly and prolong production line downtime. A combination of advanced automation and features that increase efficiency and flexibility can significantly boost productivity. Human intervention is reduced to a minimum.

In Europe, where electronics manufacturers typically produce a wide variety of products for industrial, communications, medical and automotive applications in constant rotation, productivity can be significantly increased by reducing the labor associated with the resulting product changeovers. This approach also meets the future needs resulting from an increasingly intelligent and networked world of products and systems: Highly automated manufacturing is the key here to producing the large quantities of increasingly intelligent and complex assemblies that are needed at an affordable price to be used in household appliances, buildings, vehicles, industrial control systems and other fields of application.

Minimizing human intervention in the setup and changeover of high-speed surface mount assembly lines is critical to avoid errors, delays and unproductive machine downtime. There are several effective approaches to this, using a combination of production management software to minimize the adjustments required during product changeover and additional functionality built into the equipment itself.

This can result in various labor savings. These include the elimination of tedious tasks such as changing placement heads, the automation of processes such as setting support pins, and innovations that allow routine tasks such as refilling component reels to be completed without interruption.

Reducing the changeover workload

The use of software tools to create production schedules and optimize equipment utilization is essential. Tools provided by an equipment supplier can be particularly helpful if control of key machines in the line such as stencil printers, inserters and inspection systems can be consolidated. This can take into account overall production requirements and the capabilities of specific lines and individual machines to create feeder configurations that allow for the production of multiple different products without changeovers. With proper planning, the number of changeovers required in a given shift can be significantly reduced. Downtime and manual intervention are minimized. Various packages are available, such as tools for programming and planning, production support and M2M collaboration, which are included in Yamaha's intelligent factory software YSUP.

However, to successfully minimize machine downtime and further increase productivity, manufacturers need additional tools. Every time a new setup requires a pick and place machine to be equipped with a different placement head to handle special components, or when feeders need to be replaced or simply added, the affected machine and often the entire line must be stopped so that skilled operators can complete the task.

There are various approaches to solving this problem. Several placement machines can be installed inline, each of which is optimally set up for placement of specific component types. A chip shooter designed for the placement of small, commonly used components such as SMD passives can be installed in front of a flexible pick and place machine that can handle a wider range of components. This may not be ideal in all cases as it requires additional investment in equipment and additional space in the factory.

When capital budgets are tight and production space is at a premium, manufacturers can benefit from using a single, flexible pick and place machine that covers all placement requirements. To this end, Yamaha has developed the YRM20 pick and place machine with new features that increase flexibility and automate processes that traditionally required time-consuming manual intervention.

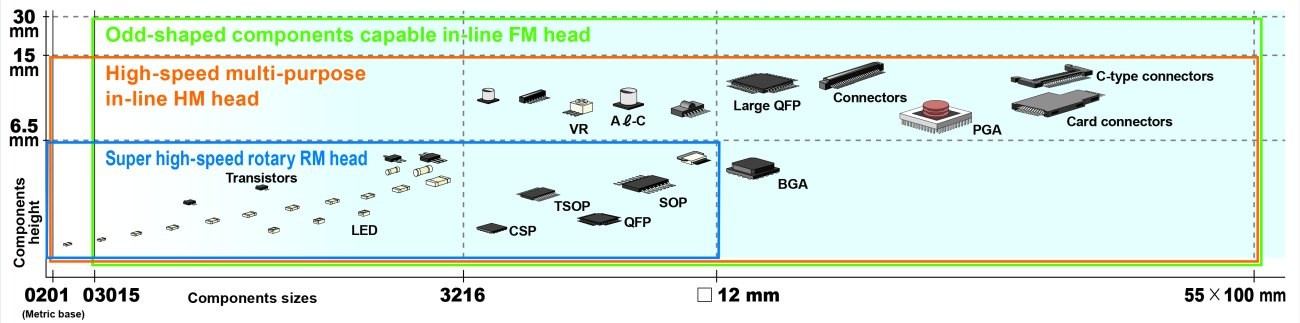

The pick and place machine is based on Yamaha's single-head concept, which now enables even higher productivity with the RM high-speed rotary head(Fig. 1). This head operates with a placement capacity of 115,0000 CPH and can place components from 0201 (mm) (SMD chips) up to parts of 12 x 12 mm and 6.5 mm in height. It enables the placement of components such as large LEDs and common IC designs such as Chip Scale Package (CSP), Quad Flat Package (QFP) and Thin Small Outline Package (TSOP) at extremely high speed. There are also new feeders optimized for the RM head, which feed the parts at high speed and ensure precise pick-up.

Fig. 2: The RM head as well as the HM and FM heads cover the entire spectrum of surface-mounted components

Fig. 2: The RM head as well as the HM and FM heads cover the entire spectrum of surface-mounted components

In addition, Yamaha's universal HM head extends the range of components to include larger components such as electrolytic capacitors, BGAs and various types of connectors. A third option, the ultra-flexible FM head, is suitable for an even wider range, including odd-shape components and parts up to 55 x 100 mm and 30 mm high. Figure 2 shows the typical shapes that the different heads can handle.

The YRM20 pick and place machine is available in various configurations with one or two beams, giving the user the flexibility to operate two heads simultaneously. To maximize the throughput possible with a dual-head configuration, Yamaha has incorporated the overdrive drive technology proven in the Sigma family of high-speed pick and place machines. This increases productivity as both heads can work together with minimal mutual interference(Fig. 3). Also based on Sigma technology, the YRM20's two-stage transport system improves PCB support and processes boards up to 510 mm wide at high speed to significantly reduce changeover times.

Automation of product changeovers

The automation of various aspects of product changeovers also helps to reduce human intervention to save time and avoid errors. Automatic program changeover eliminates the need for the operator to search for the correct program to load and instead calls up the correct pick-and-place program by scanning the barcode of the next assembly to be produced. In conjunction with a driven tool array, the combination of automatic program changeover and automatic support pin exchange eliminates another tedious manual task when changing products.

Self-loading feeders are also available. These allow the operator to quickly change the component rolls when they become empty. They ensure that the new carrier belt is inserted correctly without having to stop the machine. With Yamaha's ALF auto-loading feeder, a new belt can be loaded in just five seconds.

With the YRM20 placer, Yamaha has now extended this concept of non-stop changeover to parts that are normally presented in trays, such as large ICs and connectors. The eATS30 non-stop tray feeder feeds these components continuously and has an optimized refill process. A single tray or a complete magazine of up to 10 trays can be loaded without stopping the machine, significantly increasing productivity.

Conclusion

By reducing labor-intensive machine set-up tasks, such as changing placement heads and extending non-stop component replenishment to tray components and reels, previously required routine human intervention can be greatly reduced. The benefits include a lower error rate and longer machine uptime, both of which contribute to higher productivity.

When experienced operators are relieved of these simple tasks, they can focus on tasks that rely heavily on human skill and judgment, such as quickly diagnosing - and resolving - the causes of unexpected failures that can occur at any time. There are additional tools such as Yamaha's QA Option software, which combines the benefits of human experience and advanced automation to achieve the ultimate goal: continuously increasing productivity.