With IPC-8921, the IPC has for the first time published a basic guideline for e-textiles, which deals with the principles for this relatively new product type. Among other things, it explains 20 new technical terms and contains numerous definitions for the new product area. The document was produced as part of the IPC E-Textiles Initiative and is the first in a series of guidelines that are currently being developed.

The US industry association IPC had agreed to support the new supply chain and the producers of e-textiles by jointly developing the necessary standards as part of the IPC E-Textiles Initiative [1]. No other industry association in the USA had agreed to do this. However, the IPC was able to draw on some of the experience gained from its work on guidelines for laminates and flexible printed circuit boards, for example.

Win-win situation

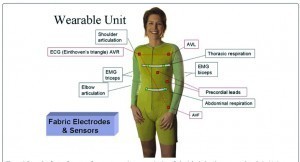

Fig. 1: Examples of the wide range of applications for e-textiles in the medical sectorThesupply chain for e-textiles works with the association to develop industry standards, create training materials and promote the further development of e-textiles.

For its part, the IPC offers members of the growing e-textile industry the opportunity to participate in both electrical testing and improving the reliability of these new products, particularly from an electrical function perspective.

In line with its working style, the industry association has also founded a new conference for e-textiles, which was organized for the first time in 2018. In November 2019, it took place as IPC E-Textiles Europe during productronica in Munich in November. IPC E-TEXTILES 2020 will be held on September 29-30 in Minneapolis at the University of Minnesota.

The event will provide a platform for companies to share their expertise in e-textile technologies with representatives from the fashion design, healthcare, medical technology and sports, athletics, automotive, military/aerospace sectors (Fig. 1-4). For the IPC, this opens up opportunities for contact and exchange with industries with which it has previously had little or no direct contact.

The main focus of the conference as well as the content of the standards to be developed have a lot in common with the content of traditional conferences and the IPC's main areas of work in the traditional electronics sector. Examples of this:

IPC-8921

Fig. 2: A perhaps extreme example of e-textiles in the fashion world The terms mentioned above can also be found in part in the new IPC-8921 standard. It is entitled Requirements for Woven and Knitted Electronics Textiles (E-Textiles) Integrated with Conductive Fibers, Conductive Yarns and/or Wires. Certain conceptual similarities with laminate materials for printed circuit boards are unmistakable.

The document was developed with input from 140 members of the newly formed IPC D-72 Textiles Materials Subcommittee. It establishes classifications and designations for e-textiles incorporating e-fibres, e-yarns and e-wires and standardizes key characteristics, durability tests and industry test methods. Key characteristics include electrical resistance, electromagnetic immunity (EMC), thermal conductivity, coefficient of thermal expansion (CTE), specific heat capacity, thermal shock resistance, outgassing, glass transition temperature Tg and melting point. Here, too, much of this is conceptually reminiscent of the characterization of laminates and printed circuit boards.

First joint document

IPC-8921 contains 20 new technical terms and definitions for e-textiles and lays down provisions for quality assurance and testing frequency. Although the standard is only 20 pages long, it is the first basic compilation to bring the textile industry and electronic performance characteristics together in one document. The specifications of the new standard allow similar e-textiles from different manufacturers to be analyzed and compared, i.e. benchmarks to be carried out. Product designers and manufacturers will have an industry standard for collecting comparative data on different materials and suppliers to help them source the woven and knitted e-textiles that are right for them. Development expectations and results can be better shared between user and supplier to create transparency. This allows the e-textile industry to work on a level playing field.

Interestingly, the IPC also proposes IPC standards for various workflows in the production of e-textiles, some of which are common to traditional electronics, for example IPC-9191 for process control tools.

"We are delighted to publish IPC-8921," said Stephanie Rodgers, Director of Product Development at Apex Mills and Co-Chair of the IPC D-72 Textile Materials Subcommittee. "This international guideline represents the collective knowledge of OEMs/brand owners, EMS companies, electronics and product design teams, material suppliers, universities, test labs and designers. For the rapidly changing field of e-textiles, we are proud to offer best practices to the industry."

IPC-8921 consists of eight chapters and costs $79 for IPC members and $158 for non-members. Further information on the standard is available via [2]. It can also be ordered directly from there. It is currently only available in English.

Further documents on e-textiles from the IPC

Two white papers (studies) have been available for information in the IPC Documents Shop since 2018:

- IPC-WP-024, IPC White Paper on Reliability and Washability of Smart Textile Structures - Readiness for the Market (published August 2018) [3]

- IPC-WP-025, IPC White Paper on A Framework for the Engineering and Design of E-Textiles (published April 2019) [4]

Future standards

The Standard Committee for E-Textiles is currently working on the development of these three standards [1]:

IPC-8941, Guideline on Connections for E-Textiles

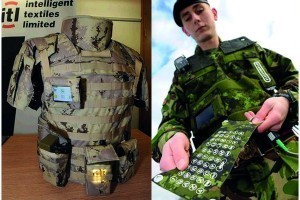

Fig. 3: E-textiles are already a widespread component of military equipment Processor: D-71 E-Textiles Joining and Interconnection Techniques Subcommittee

This industry guideline contains important considerations and best practices for joining e-textiles to (electrical) components. These may be those that provide specific electrical functionality to the e-textile or those components that are attached to e-textiles to enhance their performance.

The document is intended to help users and manufacturers work together to make the best decisions for selecting connector types, connection materials and connection processes based on the e-textile technology to be used and the component to which the e-textile will be connected.

IPC-8952, Design Standard for Printed Electronics on Coated or Treated Textiles and E-Textiles

Author: D-73a E-Textiles Printed Electronics Design Standard Task Group

This guideline defines specific requirements for the design of printed electronic applications and the forms of component assembly and interconnection structures on coated or treated textile substrates. A carrier textile for the purposes of this standard could be a bare (blank) textile or an integrated e-textile (e.g. woven or knitted e-textile).

For the purposes of this standard, coated or treated textile substrates are textile substrates that have or will have a coating or treatment distributed locally or over the entire substrate.

IPC-8981, Quality and Reliability of E-Textiles Wearables (Quality and Reliability of E-Textiles Wearables)

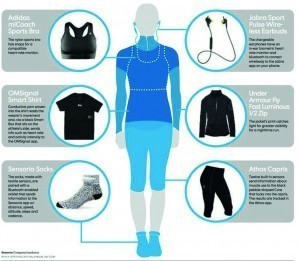

Fig. 4: Smart sportswear of the futureProvided by: D-75a-EU E-Textiles Wearables Standard Task Group in Europe

The directive defines the required test and reliability expectations for wearables products for e-textiles. For the purposes of this standard, wearable e-textiles are defined as any wearable product that includes a complete system of non-electrical textiles and e-textiles (woven, knitted, printed, etc.) with attached/connected functional components, sensors, devices, etc. A first task of the working group is to clearly define the wearable e-textiles as well as other e-textile structures that can be part of a system (e.g. wires on textile, laminated conductive polymers, sensors, actuators, etc.).

Other topics covered by the committee include

- Testing requirements for e-textiles

- for high-voltage applications

- Specification for conductive fibers, yarns

- and wires for e-textile applications

- E-textiles for home textiles

The product area of e-textiles, which is gaining speed, is particularly interesting in that it brings together classic electronics, printed electronics and textile technologies and allows the realization of new types of products with new applications. These are not only related to humans, but can also be widely used, for example, in the animal world, in interior and exterior architecture, in medical technology and in the automotive sector.

The importance of the above-mentioned standardization projects for the future widespread introduction of e-textiles can be particularly well measured if one considers forecasts that in a few years, the classic smartphone will be at least partially obsolete as a portable extra device because it will be integrated into smart clothing in a new design - along with many other sensory functions. At some point, e-textiles may become part of a smart, networked world via wireless communication. The first steps in this direction can already be seen.

Cooperation required

Chris Jorgensen, Director for Technology Transfer at the IPC and responsible for the development of the aforementioned standards, emphasized the importance of these new guidelines for the very promising product area of e-textiles, which is still in its infancy, at the end of January this year and called on all interested parties to get involved [1]. He can be reached as follows: Phone Office: +1 847-597-2826, Mobile: +1 773-682-2900, Email:

This email address is being protected from spambots. You need JavaScript enabled to view it..

References:

Fig. 1: Examples of the wide range of applications for e-textiles in the medical sectorThesupply chain for e-textiles works with the association to develop industry standards, create training materials and promote the further development of e-textiles.

Fig. 1: Examples of the wide range of applications for e-textiles in the medical sectorThesupply chain for e-textiles works with the association to develop industry standards, create training materials and promote the further development of e-textiles. Fig. 2: A perhaps extreme example of e-textiles in the fashion world The terms mentioned above can also be found in part in the new IPC-8921 standard. It is entitled Requirements for Woven and Knitted Electronics Textiles (E-Textiles) Integrated with Conductive Fibers, Conductive Yarns and/or Wires. Certain conceptual similarities with laminate materials for printed circuit boards are unmistakable.

Fig. 2: A perhaps extreme example of e-textiles in the fashion world The terms mentioned above can also be found in part in the new IPC-8921 standard. It is entitled Requirements for Woven and Knitted Electronics Textiles (E-Textiles) Integrated with Conductive Fibers, Conductive Yarns and/or Wires. Certain conceptual similarities with laminate materials for printed circuit boards are unmistakable. Fig. 3: E-textiles are already a widespread component of military equipment Processor: D-71 E-Textiles Joining and Interconnection Techniques Subcommittee

Fig. 3: E-textiles are already a widespread component of military equipment Processor: D-71 E-Textiles Joining and Interconnection Techniques Subcommittee  Fig. 4: Smart sportswear of the futureProvided by: D-75a-EU E-Textiles Wearables Standard Task Group in Europe

Fig. 4: Smart sportswear of the futureProvided by: D-75a-EU E-Textiles Wearables Standard Task Group in Europe