Human-machine interfaces (HMIs) can be found in almost all areas of the modern working world where people interact with machines or devices. These interfaces include display types such as intuitive touch displays. The optical bonding process is used here.

Depending on the area of application of the machines and devices, the displays must be able to withstand the respective environmental conditions or meet certain hygiene requirements. The optical bonding method is suitable for such requirements. In this process, touch displays are connected to touch sensors and cover glasses in an airtight manner.

The glass front is connected to the touchscreenWithoutoptical bonding, there is an air gap between the display and the front glass with the touch sensor. Condensation can penetrate this gap and impair the functionality and service life of the devices. During optical bonding, this air gap is filled with a bonding material, a special adhesive. The adhesive prevents condensation moisture from forming in the device. The bonding material also prevents the ingress of dust and dirt particles, which is particularly important when HMI systems are used outdoors, such as in agricultural vehicles.

The glass front is connected to the touchscreenWithoutoptical bonding, there is an air gap between the display and the front glass with the touch sensor. Condensation can penetrate this gap and impair the functionality and service life of the devices. During optical bonding, this air gap is filled with a bonding material, a special adhesive. The adhesive prevents condensation moisture from forming in the device. The bonding material also prevents the ingress of dust and dirt particles, which is particularly important when HMI systems are used outdoors, such as in agricultural vehicles.

Another challenge for outdoor HMI systems is solar radiation. Daily exposure to sunlight can cause devices to overheat and become inoperable. This can be prevented by optical bonding, as the bonding material efficiently dissipates the heat to the outside. The bonding material also transfers the heat lost from the LED backlight and the display surface to the cover glass, preventing the LEDs from overheating and extending their service life.

Optical bonding also helps to improve readability. While light is refracted and reflected in the presence of an air gap, a touch display filled with bonding material increases contrast. This is because the bonding material has similar optical properties to glass and therefore ensures a glare-free appearance.

As the cover glass is firmly bonded to the display after optical bonding, it acts as shatter protection. This makes the devices more resistant to vibrations and impacts.

Cost-effective and time-saving process

Bopla uses two different processes, dry bonding and wet bonding. In dry bonding, also known as laminating, the bonding material is cut to fit the visible display surface and the air gap between the front glass and the touch sensor is filled evenly. This requires the touch sensor to be flexible or semi-flexible. A highly transparent adhesive layer is laminated behind the cover glass. This process is cost-effective and time-saving and is well suited to large quantities that need to be produced in a short time, but has limited options for printing on the cover glass.

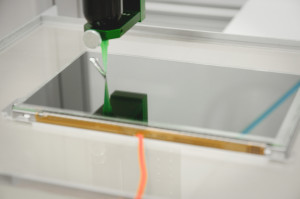

Wet bonding, on the other hand, is suitable for hard-to-hard connections where a rigid sensor is to be bonded to the cover glass. A liquid adhesive is applied to the touch sensor and then cured using UV light. This process is flexible and gentle on the material. However, it is less suitable if a frameless or zero-bezel display is to be produced.