Industry 4.0 poses increased challenges - also for incoming goods. The use of modern incoming goods systems makes sense so that the growing volume of data can be evaluated efficiently, sensibly and profitably.

In many cases, goods receipt at the customer's premises is limited to a comparison between the delivery bill and the delivered goods: Have the correct parts been delivered in accordance with the order? Do the specified delivery quantities match the quantity actually delivered? A limited quality check is carried out separately for individual components. Real traceability looks different.

With the high legal requirements that exist today, it is imperative to know exactly which material from which manufacturer from which production batch has been installed in which exact position in a product. Only precise knowledge of this data creates transparency and legally compliant traceability.

Very often, however, companies say that traceability only causes additional costs that the customer does not want to pay. However, this product assurance is a legal requirement and part of the quality of a product. It should therefore be part of every calculation.

Just like material handling in production, goods receipt also needs to be rethought. A modern and legally compliant goods receipt solution must offer manufacturers and customers advantages - including cost benefits. To the author's knowledge, many currently available goods receiving solutions do not meet this requirement. Modern goods receiving solutions, on the other hand, are the gateway to further optimized material logistics, which can generate significant cost savings and are therefore a basic building block of internal logistics.

In the following, the further development of such incoming goods solutions will be illustrated with examples from practice.

The previous goods receipt

Up to now, we have been recording batches and sticking an ID on each container - this has proved successful. But what defines a batch? For quite a few ERP users [1], it corresponds to a delivery note item. Around ten component rolls are delivered for this item. This includes products from three different manufacturers and from five different production batches. If this is not broken down further, you can expect major problems in the event of a warranty claim or damage.

Batches should always be recorded at container or packaging level so that each one can be clearly assigned to a manufacturer, a supplier and the manufacturer batch. This is the only way to clearly trace the container-specific properties, which helps to optimize and further automate logistics and reduce costs.

Some users limit themselves to photographing each roll and simply saving the image with the delivery bill. This is certainly an option, but it requires time-consuming manual capacity, both for recording and for any necessary research.

The modern incoming goods department

Goods receiving tables, which were specially designed for recording component rolls in the electronics industry and are now widely used, are a step in the right direction. However, their use also requires consistent data recording. In a time-consuming 'teach-in phase', only the labels are recorded according to defined parameters. These contain relatively little information, are usually incomplete and only record the data explicitly read from a container. This approach is inadequate for a modern and holistic logistics process. This is because such a solution achieves greater transparency, but no usable cost benefits for the entire logistics chain. In addition, almost all systems known to date are focused on recording component debinding rolls. However, incoming goods include many more different materials. In addition to classic SMT component reels, it also includes other SMT packaging forms, THT material, housings, PCBs, consumables such as pastes and adhesives.

A modern incoming goods solution must therefore process significantly more information. The different materials place corresponding demands on the systems used with regard to their recording and data processing. The wide range of additional information must be processed accordingly in order to be able to use it later within the logistics chain.

Requirements of Industry 4.0

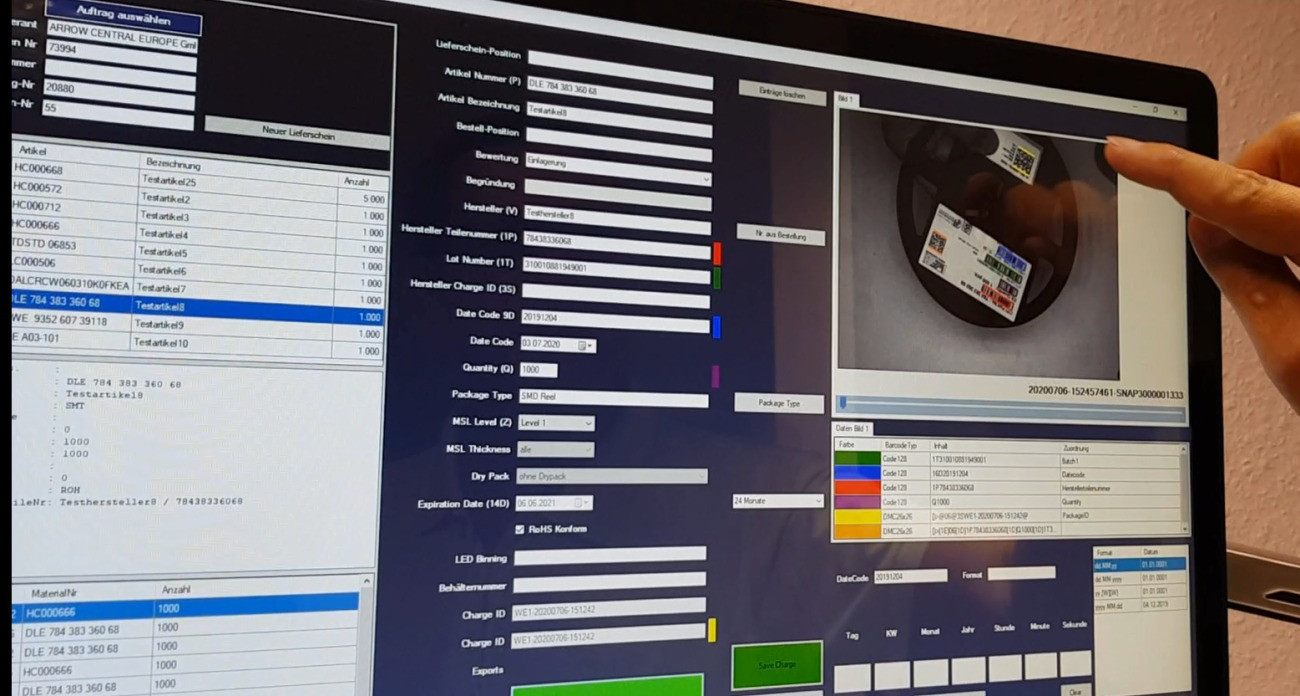

With modern goods receiving solutions, goods receiving is becoming the central element of modern material logistics. They provide a wide range of additional information about the containers and materials, their condition and properties. High-performance camera systems offer significant time and cost benefits and, as always, the 'intelligence' of such a system lies in the associated software, which processes and prepares this data and makes it available to subsequent processes for use.

In addition to pure delivery and container data, various other information must be recorded and processed that is necessary for quality assurance and subsequent use, such as container shapes, alternative materials and ownership information. Modern incoming goods systems integrate quality, measurement and inspection systems and thus create a comprehensive reference from the order to delivery note processing, quality and container data recording through to the automated provision of data to merchandise management systems and various production units.

State-of-the-art incoming goods solutions also offer the option of recording all materials via a solution concept - e.g. using mobile hand scanners. Here again, the software is the decisive link between the stationary goods receiving table and a mobile solution. This also makes it possible to receive palletized goods, large packaging units for enclosures or materials for climate-controlled storage from any location. Both solutions - stationary via the goods receiving table and mobile via the hand scanner - work with a shared database and are connected to the ERP system via a standardized ERP data interface. This also reduces the connection effort to a minimum.

Nevertheless, the scope of a goods receipt system suitable for Industry 4.0 is far from complete. In addition to the ERP connection interfaces, incoming goods solutions must provide further system connections, e.g. to forward data to storage systems, SMD assembly systems, printing and dispensing systems.

Automatic parameter analysis and assignment

Automatic parameter analysis and assignment

Dipl.-Ing. Raphael Podgurski, Managing Director of abp Automationssysteme

Dipl.-Ing. Raphael Podgurski, Managing Director of abp Automationssysteme

This networking eliminates many manual registration and documentation tasks. Picking processes, material provision processes and inventory management can be largely automated. The result is not only comprehensive transparency in the subsequent logistics processes, but also sustainable cost savings: employees are relieved of unproductive activities, a high level of transparency and an up-to-date database are achieved. Above all, the data recorded in the incoming goods department is available globally at the right time for the entire production process, wherever it is needed.

References

[1] An Enterprise Resource Planning (ERP) system is used to support all business processes in a company across all functional areas. Accordingly, it contains modules for the areas of procurement/materials management, production, sales, research and development, plant management, human resources, finance and accounting, controlling, etc., which are linked together via a common database. Cf.: Richard Vahrenkamp, Christoph Siepermann, Enterprise Resource Planning System, Gabler Wirtschaftslexikon (online): www.wirtschaftslexikon.gabler.de/definition/enterprise-resource-planning-system-51587