The 12th ASYS Technology Days took place under the motto '30 Years and Beyond' to mark the company's anniversary year. At the headquarters in Dornstadt, presentations and workshops looked back on an eventful history as well as forward into the future, with live demonstrations of new process and line solutions through to autonomous store floor solutions.

After the official welcome of the more than 300 participants by Thorsten Frenzel, Head of Sales Europe at ASYS, the three managing directors addressed the mission, situation and innovations of ASYS in a joint presentation entitled 'Return to the Future'.

Mission and portfolio: Automate, Digitalize & Connect

Fabian Autenrieth (Product Manager) answered numerous questions during a tech session

Fabian Autenrieth (Product Manager) answered numerous questions during a tech session

Werner Kreibl described the mission of the ASYS Group with the words: "Automate, Digitalize & Connect". These words describe what ASYS does and the demands it places on its products and solutions. This combination is unique in the industry.

Klaus Mang and Werner Kreibl started ASYS 30 years ago as a two-man company. Since then, the company has developed steadily. It now has over 1300 employees worldwide and covers 80% of an SMT line with its products.

Five years ago, the two company founders decided not to sell their company in view of their age, but to bring another managing director on board, Jürgen Ries. Then, as Klaus Mang explained, the Covid pandemic caused a cutback with two-shift operation as a safety measure and a persistently tense delivery situation soon followed: all in all, a mammoth task. "The captain doesn't leave the ship in a storm," said Klaus Mang and continued: "It's not getting any easier." The company needs to be realigned. The three business divisions Electronics, Life Science and Energy were formed in line with the current areas of focus, making the company more stable overall and promoting synergies in terms of technologies and products. Jürgen Ries noted that printers are an example of this.

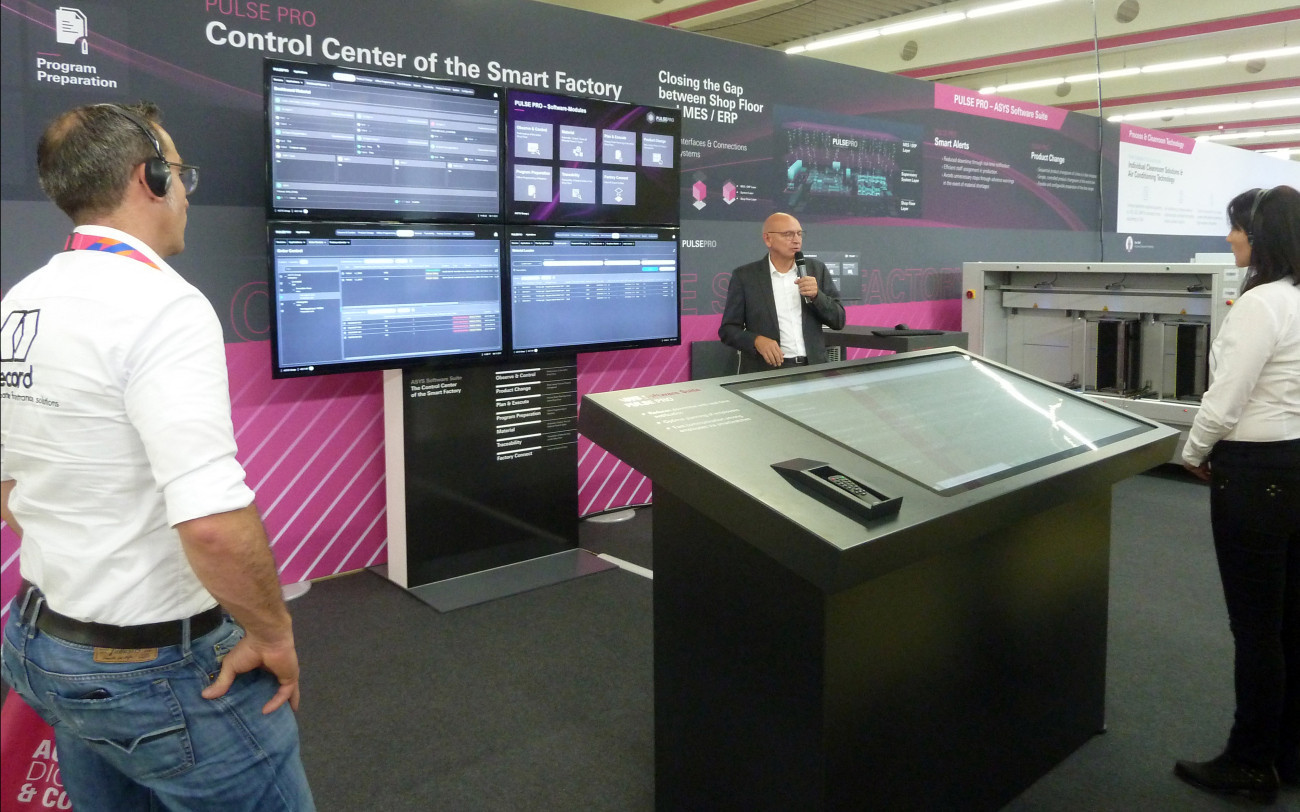

New products show where development is heading

The new Divisio 5100 for blanking is a smart machine, designed as a completely modular system comprising hardware and software and is therefore also scalable. It works with a digital twin, which enables offline programming, among other things, and records all faults. A similar example is the fully automatic Serio 6000 printer. Other innovations mentioned by Thorsten Frenzel in the 'Overview Exhibition' are the new material supply solution through to loading from Totech, the web-based PULSE PRO software, a comprehensive monitoring system whose dashboard provides a complete material and system overview, and the VEGO Smart Machines (VSM), the step towards smart handling. Even the smallest transport module is 'connected' in line with the ASYS mission. This allows the VEGO modules to trigger an automatic product changeover. No time is lost during the changeover: either manually at the touch of a button or by automatically capturing the order ID, e.g. using a cell phone camera, the entire production line changes over sequentially or in parallel as required.

The future through partnership and sustainability

Johann Weber (Zollner Elektronik) took to the stage as a surprise guest. As a major customer of ASYS, he spoke about the importance of partnership in business and reviewed the history of cooperation between the two companies in his speech, which had the character of a laudatory speech. He said: "If you are looking for a supplier, you will never find a partner." Because partnership does not mean that (only) the partner creates. Rather: "Real partners have only one goal: joint success." In this way, they can grow together and grow closer. The technical challenges of the longboards triggered the start of the collaboration. A new solution had to be found for solder paste printing. Traceability was also required. The solution was developed together, laying the foundation for many years of successful collaboration. As a message for the future, Johann Weber said that the greatest threat to a successful future is success in the past and present. However, we must always be prepared for the future. Sustainability requires a strategy for transformation. He recommended the 'Pestel Analysis' to measure sustainability. Johann Weber then turned to the two ASYS founders Mang and Kreibl and recommended that they pass on their wealth of experience as coaches, trainers or supervisory board members for their later retirement.

Technology tour offered an overview of the entire portfolio

The visitors were divided into groups for the technology tour. The products and solutions of the entire ASYS Group were presented to them at a total of 14 stations and most of them were demonstrated live. This took place in parallel and in just a few minutes at each station. The ASYS experts limited themselves to the essentials and the innovations and referred to the opportunity to obtain detailed information in the afternoon when visiting the exhibition and at the TechSessions. The following product groups were presented:

- VEGO for handling

- Insignum for marking

- Divisio for depaneling

- EKRA for printing

- Inventus for final assembly

- Tecton for tray handling and transfer

- Cleanroom Cleanroom solutions

- PULSE PRO software.

Highlight of the Technology Days: curious visitors are shown the technological highlights of ASYS

Highlight of the Technology Days: curious visitors are shown the technological highlights of ASYS

Press conference - a pioneering role in the future too

Parallel to the exhibition and the TechSessions, the top management informed the press about plans for the future and current developments. Based on the current smart machines, Werner Kreibl discussed new human-machine interfaces such as voice control and autonomous systems. In general, scalability is currently more important, including short cycle times and throughput. The new Inventus platform designed for assembly enables ASYS to implement customer-specific systems within six months. This is because existing specific software modules can be networked and are therefore functional. In the Life Science division in particular, all synergies would be utilized, and PULSE PRO could be used for the complete planning and control of production systems. Klaus Mang added that modularization was also necessary due to personnel qualifications. In addition, there are market demands for even shorter reaction times, such as in fuel cell technology with the transition from the laboratory stage to mass production. Preparing for the future is an element behind everything. Hence the intensive communication with customers and the pioneering role of ASYS. The 'Open Day' following on from the Technology Days is also important for finding new staff. For the latter, it is just as important that ASYS is also a pioneer internally in production. The motto is: 'Keep going, keep going - don't stand still!

Demonstration of PULSE PRO as a powerful tool for the 'Smart Factory'

Demonstration of PULSE PRO as a powerful tool for the 'Smart Factory'

With the addition of Jürgen Ries to the management board, ASYS has positioned itself for the future. Jürgen Ries explained the three newly formed business units, which are geared towards the target industries of the future. Markus Albrecht, who then introduced himself, joined the EKRA team in September 2022. Previously, the business consisted of a mix of standard and special-purpose machines. Special machine construction is currently experiencing extraordinary growth. Although ASYS has also suffered from the Covid pandemic - particularly due to contact restrictions - it is in a good position. The problem is to process orders on time in the current tense delivery situation. ASYS has been investing relatively heavily (approx. 20%) in R&D activities and new products for years and will continue to do so.

In response to questions from the press, the management also commented on the increasingly important topic of sustainability. ASYS is aiming to achieve CO2 neutrality for the company by 2025 - and is well on the way to doing so. However, it is more difficult for employees to get to work in a climate-friendly way. For years, ASYS, like other companies in the Dornstadt industrial estate, has been hoping for better public transport connections - for example, a new bus route. You can read more about this on the next page.

Keynote speech 'Life means risk'

The second day started with a keynote speech by Miriam Höller. She worked as a stuntwoman and action model until she had an accident during a stunt and broke both her legs. Today she works as a speaker and entrepreneur who has her own stunt team. She began with questions for everyone to answer for themselves, including:

- Are you ready?

- What are you really passionate about?

- What is your passion?

- Who are you?

- Why do you do what you do?

- ...

She then talked about her special life path and her experiences and how she overcame the difficulties. Because 'life means risk' - you have to get out of your comfort zone and into adventure. You have to accept change, make courageous decisions, learn and grow in the process. That is life and gives you joie de vivre. Being successful is then easy. Opportunities fall at your feet - you either take them or you don't. And you can use criticism to your own advantage. When it comes to risks, control is the supreme discipline. Grief is selfishness, because nothing ever breaks completely. Höller recommended: "Keep moving and trust the process." You have to accept life as it is. "Live now and enjoy the process! Now!"

From big data to smart data

Dr. Kai Kammers, VP Global Software Development at ASYS, then spoke about 'Big Data/Smart Data'. He showed how smart data can be obtained from big data. Today, vast amounts of data are generated in many areas. This is characterized by its large quantity (volume), its high (change) speed (velocity) and its great diversity (variety). They also need to be evaluated (valuation). Working directly with big data requires a huge amount of effort. Smart data can be extracted from big data using special algorithms. Dr. Kai Kammers used the example of the Divisio 8000 depaneling machine to illustrate how this works and what it makes possible.

Seamless product changeover

Thomas Endler and Fabian Autenrieth, Product Manager Material Logistics at ASYS, described how a seamless product changeover can be realized. The first step is to provide the material. The PCBs, components, solder paste and other materials are stored in different transport containers. They have to be transported from the storage (cabinet) to the autoloader, which can be done using trolleys or autonomous mobile robots (AMR). PULSE PRO is used to monitor and control what is where and when. PULSE PRO can also be used to automatically change over the SMT line - from running empty to gradually adjusting the machines in the line to the new product - and, if necessary, to generate smart alerts (in the event of errors/malfunctions), whereby information can be distributed flexibly. If an autonomously operating Serio 6000 printer is in the line, it can even replace the print template itself.

Fuel cell technology is the solution

Ulf Groos, Fraunhofer ISE, presented the development 'From Catalyst Power to MEA' in his lecture, starting with the reasons for H2 technology. One problem with H2 is transportation. There is a choice between liquid form, methanol or ammonia. In principle, all forms are equivalent and cheaper depending on the planned H2 application. It should also be noted that transporting large quantities of energy by pipeline is cheaper than via the electricity grid. In addition, further development of the existing filling stations for H2 vehicles can achieve cost parity with battery-powered ones. MEAs (membrane electrode assemblies) are core components for the chemical reaction within low-temperature polymer electrolyte membrane fuel cells. Ulf Groos described their structure and function and how they can be mass-produced using modern printing equipment.

In the afternoon, a visit to the exhibition and the TechSessions was offered in the same way as the lecture. More than 80 exhibits could be experienced live at the ASYS Group Technology Days 2022. There was also plenty of opportunity to clarify detailed questions with the ASYS experts. Everyone took away lots of new impressions and information.

Confusion of responsibilities?

Rainer Braig, Mayor of Dornstadt

Rainer Braig, Mayor of Dornstadt

Getting to the Dornstadt industrial estate 'Lerchenbergstraße Ost' by public transport is not so easy: although bus route 49 runs at sufficient intervals, the journey time from Ulm main station is long and the bus stop is an unattractive distance away - especially for commuters. Companies in the business park would like to see an improvement in the situation - but this is prevented by a 'confusion of responsibilities' in public administration. The PLUS contacted the town of Dornstadt and the Alb-Kreis-Donau district office.

Rainer Braig, Mayor of Dornstadt

What is the best way to get to the Dornstadt industrial estate from Ulm by public transport?

The nearest bus stop is approx. 150 m from the industrial estate. Depending on the location of the company, the distances are correspondingly longer.

Why is the industrial estate not better connected to the public transport network?

The route would have to be changed, which would be disadvantageous for other areas in Dornstadt. If the bus were to travel even longer, this would lead to conflicts with the Ulm connection point. In addition, a route with a long journey time would become unattractive.

Couldn't a new bus route significantly improve the connection?

As the municipality of Dornstadt, we would like this in order to better connect other areas in addition to the industrial estate. We have not yet been able to persuade the relevant authorities to do this. There is also a local transport concept for the Alb-Donau district from 2015, according to which all standards are met and Dornstadt is adequately supplied. A new bus route is therefore not foreseeable at present.

Katrin Frauenlob, Alb-Donau district administration office

How many employees commute between Ulm and Dornstadt?

According to the 2021 Commuter Atlas Germany, 1,861 people commute from Dornstadt to Ulm. In the opposite direction, there were 818 commuters from Ulm.

Many commuters find the connection to the industrial estate unfavorable, which is why they cannot do without their car ...

Bus route 49 serves the stops at half-hourly intervals during working hours. The distance to the local companies is usually less than 500 meters. This is considered sufficient in the local transport plan of the Alb-Donau district. Line 49 between Dornstadt and Ulm is the most densely served bus line in the Alb-Donau district overall and exceeds the requirements of the local transport plan.

Could a new bus route improve the situation?

Companies can contact the district administration office with specific concerns in order to find solutions together with the responsible transport companies. Bus route 49 is approved as a self-sufficient service: The bus company can organize the route independently.

Under what circumstances would a better connection be possible?

According to the 2015 local transport plan, no inner-city transport is planned for Dornstadt. Although this is generally put out to tender by the Alb-Donau district office, the financial responsibility for this lies with the respective municipality.