Modern electronics production is characterized by a large number of different separation and joining processes. Joining processes account for the majority of production processes. In addition to bonding, welding and laser processes, soldering continues to play a primary role in the production of electronic assemblies.

However, not all soldering is the same, as there are also different technologies in this area. A distinction is also made between automated and manual soldering processes. But no matter which soldering process you analyze, they all have one thing in common: they all produce airborne pollutants that can have negative effects on employees, equipment and products.

Soldering processes in electronics production

There is a whole range of soldering processes, but not all of them are used in electronics production. Common soldering techniques in component production are

- Wave soldering or wave soldering

- reflow soldering

- dip soldering

- Hot air soldering

- Selective soldering

- Laser soldering

- Vacuum soldering

In the manufacture of electronic assemblies, soldering processes that work with soft solder are used almost exclusively. The melting temperature of the solder is lower than that of the elements to be joined, e.g. connections of components to the conductor tracks (approx. 180 °C to 260 °C). The molten solder flows between the metal parts. The aim is to create a solid, airtight, corrosion-resistant, current- and heat-conducting connection between the solder and the metals.

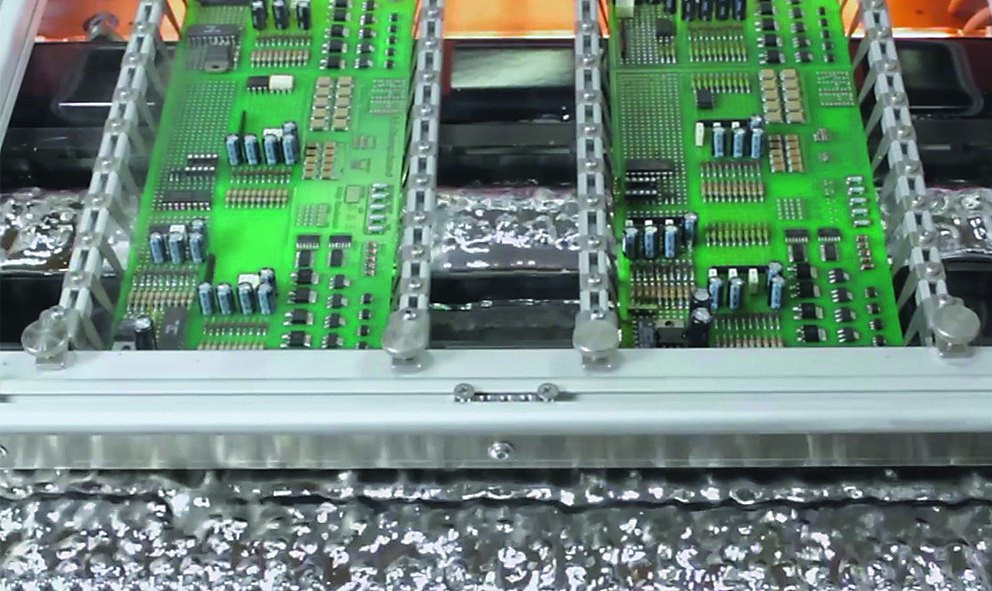

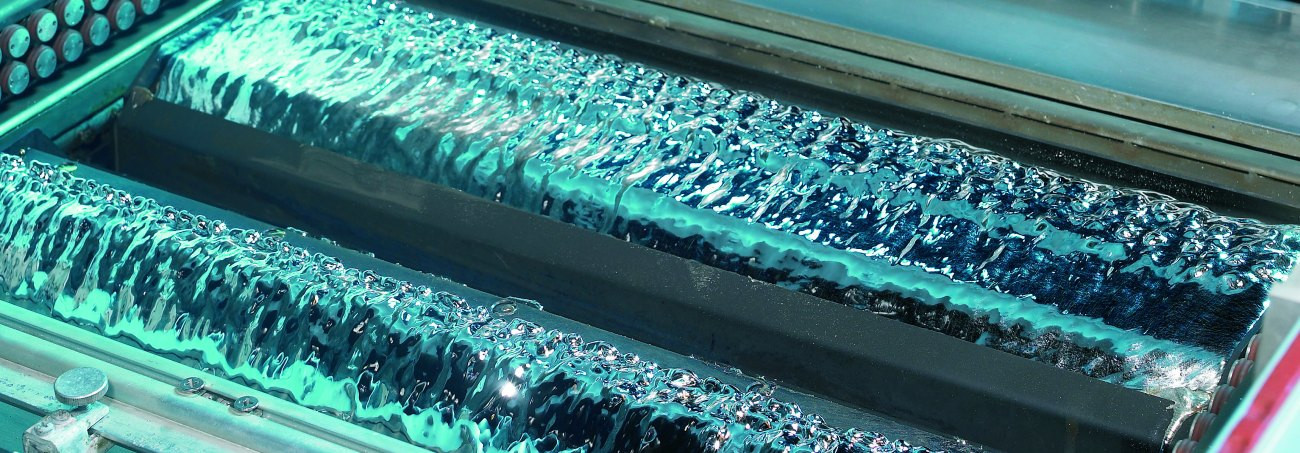

During wave soldering, the assembly is immersed in the liquid solder - the resulting vapors must then be reliably extracted

During wave soldering, the assembly is immersed in the liquid solder - the resulting vapors must then be reliably extracted

The solders usually consist of alloys - as solder wire, solder bars or solder paste. Depending on the application of the end product, these consist of tin, lead, antimony, silver and/or copper. They may contain fluxes consisting of different chemical compositions, e.g. rosin. In principle, so-called halogen-free fluxes are used, whereby their effect relates to the soldered joints.

Automated soldering processes and manual soldering

Where a few decades ago hard-working people soldered assembly after assembly, today automated soldering systems of various sizes are used. These systems are specialized systems that perform a specific soldering technique, e.g. reflow soldering or selective soldering. These systems are used depending on the type of assembly and batch size. In many production lines, there are different systems that are used according to their purpose.

However, soldering at manual workstations is still an essential part of assembly production. However, manual soldering tasks are mainly carried out for small series, prototype construction or at repair stations.

Airborne pollutants that occur

Solder fume extraction at the repair workstationDependingon the application of the assembly and the requirements of the components used, different solder alloys and fluxes are used during soldering. During the soldering process, large parts of the flux and a small proportion of the solder are vaporized and the resulting aerosols and particles can enter the production area.

Solder fume extraction at the repair workstationDependingon the application of the assembly and the requirements of the components used, different solder alloys and fluxes are used during soldering. During the soldering process, large parts of the flux and a small proportion of the solder are vaporized and the resulting aerosols and particles can enter the production area.

This not only spreads unpleasant odors. These airborne pollutants can also cause serious illness among personnel. A particularly dangerous product here is aldehydes, which are formed from substances containing colophony, some of which can be carcinogenic. In addition, gases are produced during heating from parts of the protective coating, adhesive or carrier materials of the assembly.

These gases also contain sticky aerosols that settle in the soldering machines - and in the worst case on the products - and contaminate them. This then leads to increased maintenance costs, as the functionality of the system can be impaired. In addition, the manufactured products can become contaminated or even corroded, which has a negative impact on their functionality and consequently on quality.

In conventional wave soldering processes, the entire surface of the PCB is usually wetted with flux. The resulting spray mist from alcohol-based fluxes can lead to explosive, highly flammable vapor-air mixtures in conjunction with further damping of the assemblies.

Differentiation and legal regulations

Airborne pollutants are generally classified according to particle size. This classification is primarily based on the impact of emissions on the human organism. Airborne pollutants are not only differentiated according to whether they are harmful to the brain, nerves or respiratory tract, but also whether they are inhalable (E fraction) or alveolar (A fraction). Pollutants of the A fraction overcome the so-called blood-air barrier, which separates the air-filled space of the alveoli in the lungs from the blood in the capillaries.

There are legal limit values for this in accordance with DIN EN 481, which are 10 mg/m³ for the E fraction and 1.25 mg/m³ for the A fraction (since 1.01.2017) in accordance with TRGS (Technical Rules for Hazardous Substances) 900. The statutory provisions of TA Luft (Technical Instructions on Air Quality Control) stipulate a total dust mass concentration including particulate matter of 20 mg/m³.

Capturing air pollutants and their sustainable filtration

The threefold damaging effect of soldering fumesIn order toeliminate air pollutants, it is not enough to ensure good ventilation in the production environment. The use of efficient extraction and filter technology is required here and is also prescribed accordingly by the employers' liability insurance association.

The threefold damaging effect of soldering fumesIn order toeliminate air pollutants, it is not enough to ensure good ventilation in the production environment. The use of efficient extraction and filter technology is required here and is also prescribed accordingly by the employers' liability insurance association.

There is a wide variety of extraction and filter systems on offer. Their use is determined by the type and quantity of pollutants, their use in automated, semi-automated or manual production processes and their mobility (mobile devices vs. stationary systems) and flexibility.

Modern extraction and filter systems achieve such a high level of purification of the process air that it can then be returned to the work area.

When using extraction systems for air purification, it is also important to capture the air pollutants. Proximity to the emission source is crucial here - the closer, the better. Not only to capture the majority of all particles before they enter the ambient air or settle in systems and on products, but also to minimize economic costs. The greater the distance between the emission source and the capture element, the higher the required suction power of the extraction and filter system - which has a lasting impact on energy consumption.

Capture elements help to increase the effectiveness of the extraction system. These are end pieces on extraction arms that ensure optimum absorption of emissions. Depending on the quantity and type of pollutant as well as air flow principles, they are available in different designs - up to complete enclosures.

The use of the 'right' capture element determines the quality of the complete extraction and filter system. This is because the level of capture is the basis for subsequent high-grade filtration, which ultimately results in efficiency and consequently the amount of residual pollutants in the recirculated air.

Summary

The competitive pressure in electronics production is high. Only those who supply high-quality products, minimize the maintenance costs of their production facilities and can rely on healthy employees can survive in a highly competitive market. The issue of air pollution control plays a central role in this.