In recent decades, the US industry association IPC has been very active and successful in developing and promoting new, internationally valid standards for the design and manufacture of electronics. However, the focus has been almost exclusively on development as well as test and acceptance procedures. IPC-1402 is the first time that the association has focused on environmental issues relating to the use of chemicals in such a document.

In January 2021, the IPC announced that it had committed to developing a new consensus-based industry standard 'IPC-1402: Standard for Green Cleaners Used in Electronics Manufacturing' [1]. This document is intended to add safer, more environmentally friendly practices to the family of over 300 IPC standards for electronics manufacturing at the time. It focuses on chemical cleaners used in the manufacture of electronic assemblies, components and materials, including the direct use of chemicals on these assemblies or for cleaning manufacturing machinery during operation and maintenance. According to the press release, the standard will define a scientifically defensible set of requirements for environmentally friendly chemistry for cleaning agents used in electronics manufacturing. It will provide another way for electronics manufacturing companies to demonstrate their commitment to protecting the environment and health and safety in the workplace(Fig. 1). The aim should be to produce more and more 'green electronics'. The 'Green Cleaners in Manufacturing Task Group' set up to develop the standard called on all interested parties to participate in the development of this important standard.

Overly optimistic deadline of February 2022

In a press release at the end of September 2021, the association issued an interim report [2]. It noted initial progress in the working group's activities. Matt Kelly, Chief Technologist of the IPC, emphasized the increasing urgency of the project: "This is an important step forward in building a sustainable ecosystem for electronics manufacturing". Accordingly, the expected delivery date of IPC-1402 was set for February 2022. Kelly set the bar very high for what he expects from this new guideline and thus from the work of the task force: "IPC-1402 will help engineers make informed decisions and select cleaners that are safer for both manufacturing workers and the environment. The standard will document the stringent criteria for preferred cleaners and incorporate industrial hygiene requirements. The application of IPC-1402 will allow important health and safety requirements to be added to design drawings needed for product assembly."

The work of the task force, led by Xu Lu (Apple Shanghai) and Terry Price (Zestron Americas Inc.), already involved industry experts from more than 20 international companies and government agencies. However, anyone who has accidentally or deliberately checked the IPC blog from time to time in recent years will certainly have noticed that both the U.S. Environmental Protection Agency (EPA) and the EU bodies have been making constant changes and new demands regarding the use of certain chemicals. This significantly hampered the task force's efforts to meet the set completion date [3].

Working draft ready by mid-July 2022

On June 22, 2022, the IPC again issued a press release in which it was able to report that, despite all the dynamic adversities, the international working group had made so much progress that IPC-1402 could be released as a working draft for public review or inspection with immediate effect. Considering that minor or major delays in the timetables for the development of drafts are quite common in the standardization process precisely because of consensus building, this is a remarkable achievement by the task force. It should not be forgotten that its members are active in very different parts of the world, such as Asia, Europe and North America, and the status of environmental legislation in these regions must be taken into account. Teresa Rowe, IPC Senior Director Assembly and Standards Technology, called on the industry to review the draft standard and send her objections and suggestions for improvement [4].

New target date of December 2022

The aim of the new standard is to achieve a global consensus on cleaning agents for the electronics industry. The IPC therefore encourages company employees whose companies use chemical cleaning agents

- on electronic products or components

- in machines and tools during operation and maintenance

to review the draft standard and provide comments to the above-mentioned working group. The draft document is freely available and reviewers can participate in the process. Although the IPC set a very short deadline for comments on this draft industry standard in June, namely mid-July, there should still be opportunities to make suggestions after this deadline. This is because there are still two more intermediate stages to be completed before the final guideline (Published Standard) is published with a target date of December 2022 [5]:

- Final Draft for Industry Review

- Proposed Standard for Ballot

Reviewers can email

What next for 'green electronics'?

If you take a look at the IPC Status of Standardization [5] of all the guidelines currently being revised or revised, you will see that IPC-1402 is actually the first document of this kind from the industry association to deal fundamentally with environmental issues on a specific topic.

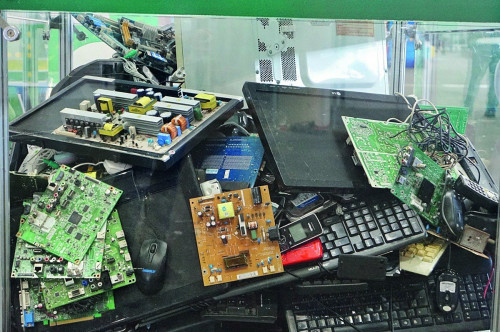

The looming energy shortage for industry and private consumers, which has been further (artificially) fueled by the Ukraine conflict, is bringing the issue of energy efficiency and energy saving for both electronic products and manufacturing processes to the fore as (probably) never before. Dr. Jan Kostelnik (Tebco) therefore commented in his article 'Energy transition and climate - do we need new AVT strategies?" in Plus issue 5/2022: "However, the most explosive current topic is the question of energy consumption and savings ..." [6]. He even puts the more energy-intensive lead-free technology up for discussion. It should therefore be considered whether new approaches to this topic could be developed under the auspices of the IPC, leading to corresponding guidelines or best practice recommendations for the design of energy-efficient electronics and energy-efficient manufacturing processes. The same applies to other environmentally relevant topics such as repair, reuse and recycling-friendly design(Fig. 2). The IPC has literally remained silent on these topics as well. It has never made a clear statement on the 3R methods (reduce, reuse, recycle) introduced in Japanese electronics companies at the end of the 1990s and has still not committed itself to this topic. However, as the current situation shows, the 3Rs urgently need to become an increasingly decisive principle of sensible and effective corporate operations. The current environmental and supply chain situation underlines with all due clarity that internationally active industry associations such as the IPC must also show more leadership in this direction. Perhaps IPC-1402 is a start in the right direction.

Can IPC Europe achieve this?

On May 25, 2022, the IPC headquarters announced that it had officially registered IPC Electronics Europe GmbH in the commercial register at the responsible local court in Germany as a subsidiary of the US industry association on May 4, 2022. The headquarters of the new company is located in the center of Munich [7]. It is intended to better support the interests of the European members.

John W. Mitchell, President and CEO of IPC, commented: "Although we have been active and successful in Europe for more than 30 years, the fact that we are now a legal entity here enhances our ability to serve the regional electronics industry and support our membership with even greater vigor and bolder activities." Let's go then, one might add ironically but hopefully.

Sanjay Huprikar, President of IPC in Europe and South Asia, added: "We are very excited about the prospects of actively participating in major consortia and working groups in the EU to help drive new standards, education and advocacy solutions that will be critical to transforming the continent's factories of the future". But the factory of the future is nothing without green manufacturing and green products.

The IPC plans to increase staff in Europe in addition to Francisco Fourcade, who joined the IPC in April as Electronics Standards Manager. The aim is to manage the growing number of new standards development committees in Europe. Over the next 18 months, the association will add more talent to the certification, marketing and industry intelligence teams. If this is successful, the IPC should focus more attention on the environmental issues mentioned above(Fig. 3).

Good foundations for more green electronics are in place

There is already a good basis in Germany for the IPC to become more active in the green electronics sector. The employees of IPC Europe would first have to gain an overview and then take the appropriate decision. One example: Fraunhofer IZM has been working on the 3R problem for almost 25 years. The author of this article attended conferences and trade fairs on green electronics in Tokyo in the late 1990s and early 2000s, as did IZM representatives. The aim was to make the Japanese 3R movement known in Germany as well(Fig. 4).

Fig. 4: Books on the Design and Manufacturing of Green Electronics

Fig. 4: Books on the Design and Manufacturing of Green Electronics

Since then, Fraunhofer IZM has carried out numerous projects on environmentally friendly electronics. In the most recent sustainablySMART project, a research team investigated what sustainable alternatives are available and how circular economy approaches can best be incorporated into the consumer sector. With their comprehensive concept, they won the 2021 Ralf Dahrendorf Prize of the BMBF for outstanding research cooperation at European level and the associated science communication [8].

With the European sustainablySMART project, the research team made a significant contribution to the understanding of the circular economy. The research focused on mobile products, such as smartphones and tablets, which have long been part of everyday life and yet leave a considerable ecological footprint. With the help of extended life cycles through innovative product designs, improved recycling and reprocessing concepts and increased resource efficiency, the team applied ideas from the circular economy to ICT devices. These are all topics that are increasingly 'burning under the nails' of industry in general.

Partners from eight European countries were involved in the award-winning project, including the high-end PCB manufacturer AT&S, the repair experts from iFixit, ReUse e. V., the Vienna University of Technology, Speech Processing Solutions from the voice recorder sector and Blancco as experts in data erasure.

The findings on the implementation of the Circular Economy Policy in mobile devices are suitable for advancing green technologies and technological sovereignty in Europe. The researchers hope that the findings will also be incorporated into the European Commission's forthcoming directives [8]. This experience should also be transferable, at least in part, to commercial electronics and help the IPC to quickly develop appropriate standards collectively.

References and comments:

[1] www.ipc.org/de/node/310

[2] www.ipc.org/news-release/ipc-and-apple-develop-new-standard-green-cleaners-be-used-electronics-manufacturing

[3] www.ipc.org/blog?category=37

[4]

[5] www.ipc.org/de/Status

[6] Plus 5/2022, p. 699-701

[7] www.ipc.org/news-release/ipc-establishes-european-subsidiary

[8] www.izm.fraunhofer.de/de/news_events/tech_news/fraunhofer-forschende-gewinnen-ralf-dahrendorf-preis.html