Electrically insulating thermal conductive films have many advantages in power electronics applications. A well-balanced thermal management concept enables a longer service life of the electronic components used and therefore a higher performance and quality of the entire electronics application.

The trend towards ever smaller designs combined with increasing performance requirements makes it necessary to dissipate the heat generated by the electronics as quickly, effectively and cost-effectively as possible.

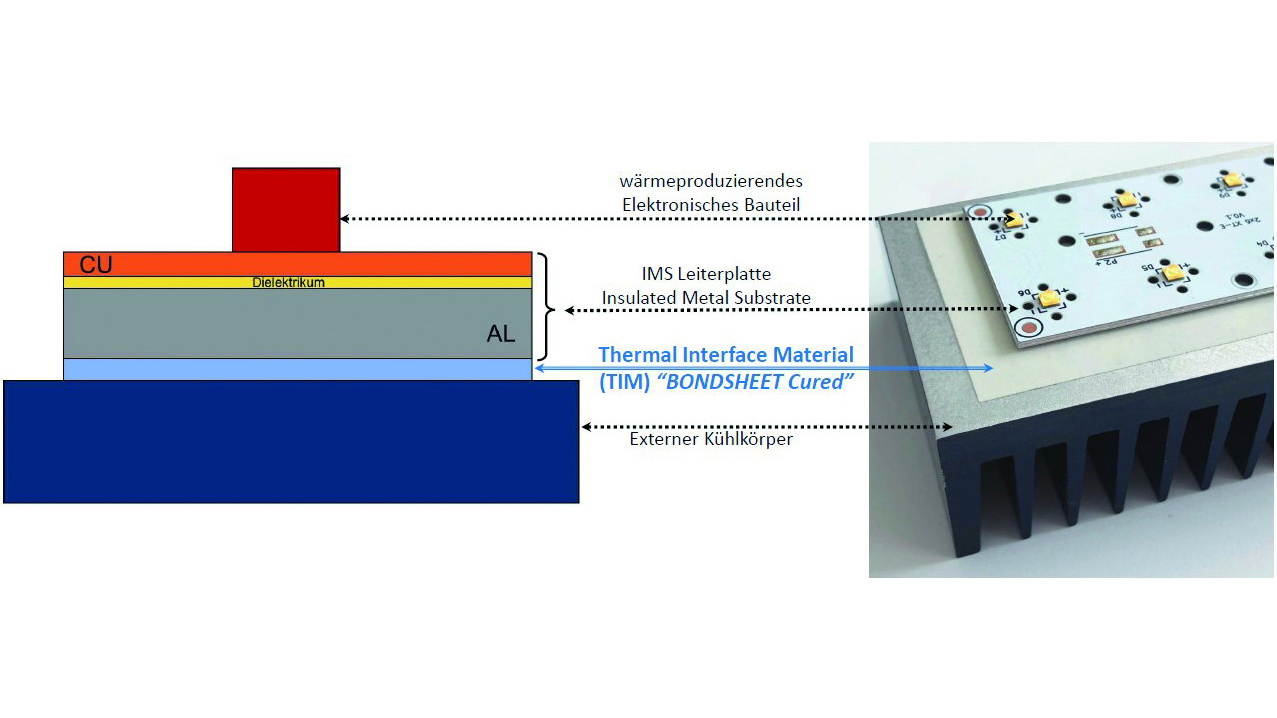

In addition to the IMS substrates it has been producing for more than 20 years, the European manufacturer of substrates (FR4, CEM and IMS) for the global PCB industry Aismalibar has developed technologies for thermally conductive films that are used to connect a heat-generating electronic assembly to a heat sink. The thermal conductivity of the film or its thermal resistance plays a dominant role. Increasingly, electrical insulation properties (to protect against contact) and the absence of silicone are also required. All these key requirements are met by Aismalibar's Bondsheet Cured thermally conductive film.

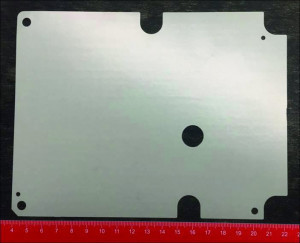

Fig. 2: Growth markets in which heat dissipation in electronics plays a central role

Fig. 2: Growth markets in which heat dissipation in electronics plays a central role

The company has been part of the Benmayor Group since 2011 and produces in its own plants in Barcelona and China. It offers a wide range of IMS technologies (insulated metal substrates) for heat-critical electronics applications. The company supplies PCB manufacturers for applications in the automotive, LED lighting, medical and industrial electronics sectors.

Wide range of applications thanks to special properties

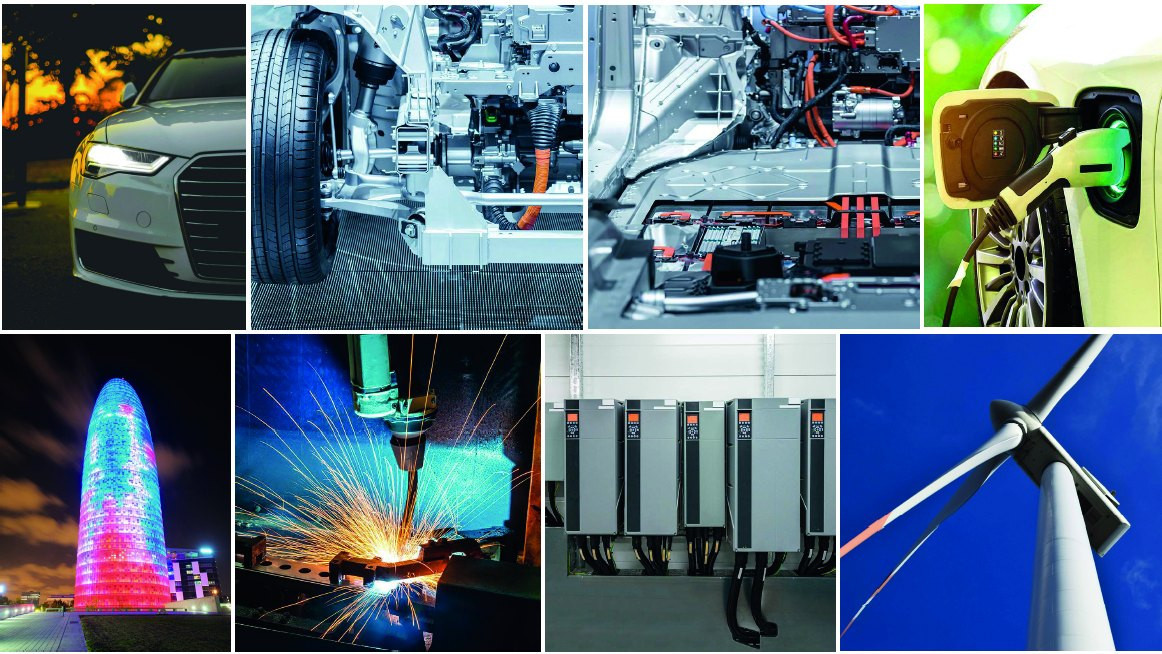

Fig. 3: Bondsheet Cured thermally conductive film in initial sizes of 1245 x 945 mm or 1245 x 1040 mm for further processing by cutting, sawing or punching (www.aismalibar.com/de/product_group/bond-sheet-cured-de)The main areas of application for TIM thermally conductive film are power electronics applications in which the connection between two flat metal surfaces is to be optimized in terms of thermal conduction and electrical insulation. The film is currently being used successfully in applications such as solar inverters and wind turbines, transmission controls for commercial vehicles and LED industrial lighting. New projects are increasingly coming from the e-vehicle sector, where they are used in the drivetrain and battery management, including on-board charging electronics. Industrial power electronics, for example in welding equipment and robot drives, also use heat conducting films to efficiently cool the control electronics.

Fig. 3: Bondsheet Cured thermally conductive film in initial sizes of 1245 x 945 mm or 1245 x 1040 mm for further processing by cutting, sawing or punching (www.aismalibar.com/de/product_group/bond-sheet-cured-de)The main areas of application for TIM thermally conductive film are power electronics applications in which the connection between two flat metal surfaces is to be optimized in terms of thermal conduction and electrical insulation. The film is currently being used successfully in applications such as solar inverters and wind turbines, transmission controls for commercial vehicles and LED industrial lighting. New projects are increasingly coming from the e-vehicle sector, where they are used in the drivetrain and battery management, including on-board charging electronics. Industrial power electronics, for example in welding equipment and robot drives, also use heat conducting films to efficiently cool the control electronics.

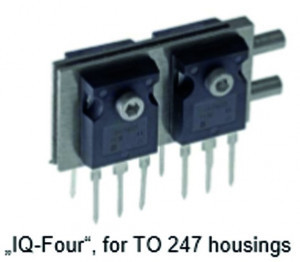

Another application example shows the cooperation between Aismalibar and IQ-evolution(www.iq-evolution.com) with the same basic task: efficient heat dissipation with maximum insulation resistance for optimum coupling of PowerMOSFET power semiconductors to the liquid-cooled micro-coolers from IQ-evolution.

Intensive tests have shown that for this application IQ-evolution achieves the best technical-commercial combination of heat dissipation and dielectric strength with the Bondsheet Cured heat conducting film compared to alternative thermal interface technologies. The key technical properties of Bondsheet Cured are:

- Thermal conductivity: 2.2 W/mK

- Film thickness: 70 µm or 100 µm

- Thermal resistance (Rth): 0.315 K/W at 70 µm, 0.450 K/W at 100 µm

- Dielectric strength (AC): ≥ 4 kV at 70 µm, ≥ 6 kV at 100 µm

- Glass transition temperature (Tg): 120 °C

Production and delivery of the heat conducting film

Fig. 4: "IQ-Four", for TO 247 housings: Application example of a liquid-cooled, highly compact MOSFET assembly for power electronicsThe starting pointfor production is a glass fabric material of type 106 or 1078/1080, which is enriched with ceramic fillers in Aismalibar's own process. In addition to the pure material properties of the fillers used (such as Al2O3, AlN, BN), the particle size, shape and distribution are decisive factors in ensuring that the initial glass fabric has homogeneous heat-conducting properties. After adding the fillers and further process steps, a B-stage prepreg is produced, which is used in multilayer production in the PCB industry.

Fig. 4: "IQ-Four", for TO 247 housings: Application example of a liquid-cooled, highly compact MOSFET assembly for power electronicsThe starting pointfor production is a glass fabric material of type 106 or 1078/1080, which is enriched with ceramic fillers in Aismalibar's own process. In addition to the pure material properties of the fillers used (such as Al2O3, AlN, BN), the particle size, shape and distribution are decisive factors in ensuring that the initial glass fabric has homogeneous heat-conducting properties. After adding the fillers and further process steps, a B-stage prepreg is produced, which is used in multilayer production in the PCB industry.

In order to produce a cured thermal conductive film Bondsheet Cured, this prepreg is then further processed using Aismalibar's own processes to achieve the thermal conductivity and insulation strength properties specified in the data sheet.

At the end of the production process, the Bondsheet Cured heat conducting film is available in the formats 1245 x 945 mm and 1245 x 1040 mm, Aismalibar's preferred delivery format. Equally popular are the standard PCB industry formats, such as 460 x 610 mm. On special customer request, Aismalibar can cut the Bondsheet Cured to any rectangular/square format and supply it in stacks of several hundred individual sheets for manual or automated further processing by the user.

For samples and prototypes or even small batches, Aismalibar contours the Bondsheet Cured film according to customer specifications, for example with rounded corners and holes, so that the film can be inserted directly between the heat sink and printed circuit board in the customer's final product assembly and assembled into a single unit. As no oils, pastes or silicones are used in the thermal conductive film, the electronic module can be assembled and disassembled cleanly (e.g. for servicing).

Fig. 5: Examples of the electrically insulating thermal conductive film contoured according to customer specifications in order to achieve optimum mechanical adaptation of the PCB to the heat sink

For high-volume series production, punching the foil with a customer-specific punching tool has proven to be the most cost-efficient series production method.

Samples of both film types with a thickness of 70 µm or 100 µm are available from stock in Barcelona.

Outlook

Aismalibar is currently developing technologies that meet or further increase the high requirements for thermal conductivity and dielectric strength. In addition, processability is also being optimized, especially for high-volume series production, e.g. in the automotive sector.

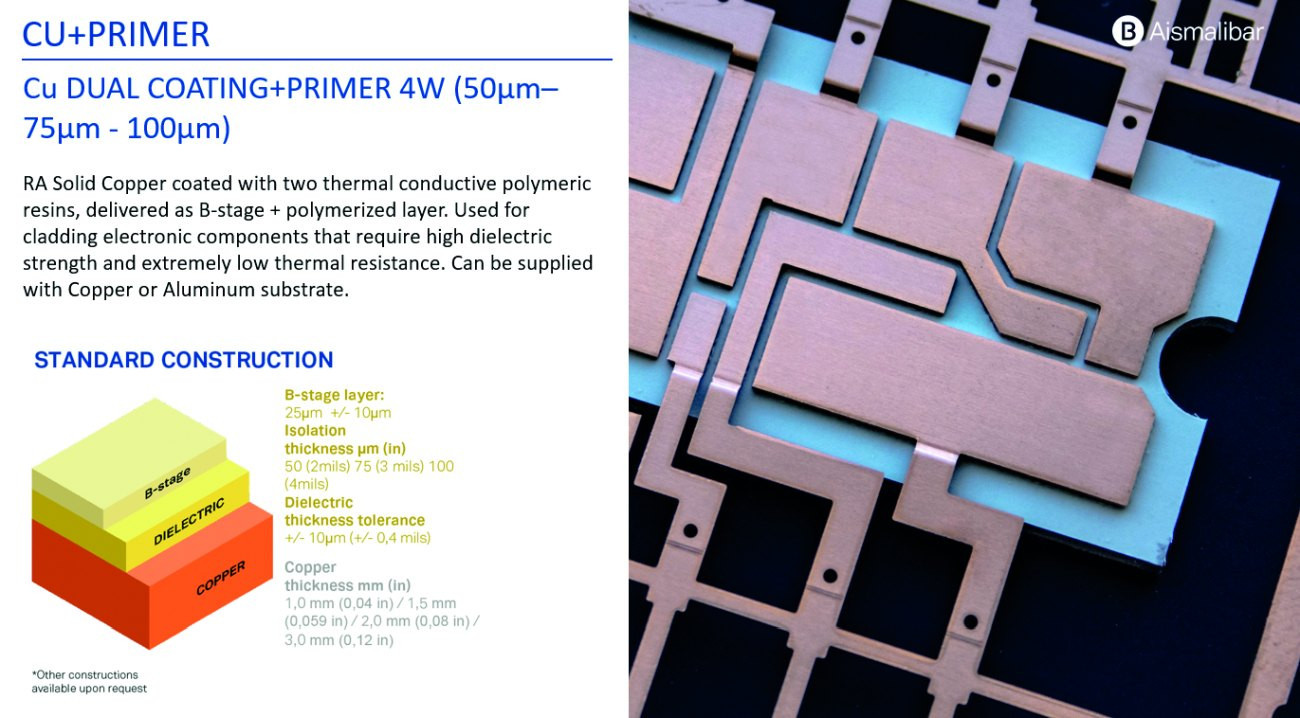

Fig. 6: New development Dual Thermal Coating

Fig. 6: New development Dual Thermal Coating

This is a process that makes it possible to apply two layers of a glassless dielectric directly to a carrier metal. This new dielectric technology makes it possible to apply the heat-conducting/insulating layer directly to a metal substrate in almost any thickness. The lower dielectric layer is already cured during the production process at Aismalibar, giving it the electrical and thermal properties specified in the data sheet. An additional B-stage layer is applied to this cured dielectric, ready for further processing by the user. In the customer's assembly process, this structure consisting of a metal carrier plus a two-layer dielectric is pressed together under pressure and heat to form a homogeneous overall unit. The result is a highly compact power module with optimized electrical and thermal properties combined with a shelf life of the processed overall unit that meets the requirements of the electronics industry.