The "Red Cube" at Munich University of Applied Sciences has been the venue for the IMAPS Autumn Conference for many years. On October 19 and 20, over 90 participants, 20 speakers and 11 exhibitors came together for the main event of the year. Traditionally, the annual general meeting of IMAPS Deutschland e.V. is also held in this context. The conference program was designed in such a way that presentations on similar topics were grouped into blocks.

After the opening and welcoming of the participants by the 1st Chairman Prof. Martin Schneider-Ramelow, there were three presentations on the topic of sintering. Benjamin Schellscheidt from Düsseldorf University of Applied Sciences presented "Investigations into a two-stage sintering process", with which a higher process throughput can be realized. This allows the pressing time in the sintering press to be reduced, followed by the second sintering step at 300 °C in nitrogen. Knud Gripp from Kiel University of Applied Sciences spoke about "Investigating the use of inductive heating in the sintering of semiconductor components". The motivation for the work is to reduce the thermomechanical stresses in the sintering layer, which is influenced by the type of heating. It was shown that the deformation of the underside of the copper substrate could be significantly reduced in the test setup, partly because the sintering paste can be cold compacted and then heated and sintered. The method offers new possibilities in sintering process control due to the thermal performance. Nihesh Mohan from Ingolstadt University of Applied Sciences dealt with the "Particle formation and trace morphology of Cu complex inks using different sintering techniques". Among other things, it was shown that the copper particles are sintered into finer structures during laser sintering compared to conventional furnace sintering. In laser sintering, the particles produced in-situ are only heated for a very short time, which prevents the particles from coalescing into larger aggregates.

The exhibitors were then given the opportunity to briefly introduce themselves in the auditorium and arouse interest for a visit during the coffee and exhibition breaks at the table tops. This opportunity was well taken advantage of, also due to the good spatial conditions directly in front of the auditorium.

The next block brought together four presentations on the topic of LTCC. Martin Ihle gave a presentation on "Maskless, digital printing processes for LTCC microcircuits". As part of the MuSKeL project - miniaturized digitally printed structures in LTCC ceramics - Fraunhofer IKTS, Hahn Schickard and Gdansk University of Technology are working on inkjet-based structuring processes that do not require screens or stencils. Peter Uhlig from IMST and Richard Schmidt from IKTS shared the presentation of the results as part of the "HEROES" project, which deals with "Ceramic multilayer circuits for high-voltage sensor technology". An alternative to Al2O3 ceramics was required for a high-voltage application, which must be encapsulated to ensure dielectric strength. The element could be produced with better performance as an LTCC multilayer with resistance layers in the inner layers. Simulations with high-resolution PI pastes promise further improvement. The presentation "Heat management and recovery system for electronics using micro-thermoelectric generators" by Nesrine Jaziri, TU Ilmenau, dealt with functional integration in terms of thermal management. The contribution by Qaisar Muhammad from VIA electronic, who dealt with "Screen-printed varistors for thick film and LTCC microcircuits", also dealt with the functionalization of ceramic circuits. IKTS is also a partner for the functional pastes, in this case special resistor pastes with varistor properties.

The first afternoon block was devoted to the topic of reliability. "Lifetime modeling of the top side contacts of SiC power semiconductors" was the title of the presentation by Rasched Sankari, Robert Bosch GmbH, who dealt with power cycling on SiC diodes and MOSFETs. The comparison of measured values under load with modeled correlations was examined. "Laser stimulated transient thermal analysis: A novel measurement technique for semiconductor reliability characterization" was the title of the paper by Hannes Schwan, Technische Hochschule Ingolstadt. The method can be used to evaluate thermal interfaces of joined semiconductors. Artem Ivanov, University of Applied Sciences Landshut, concluded the block with the presentation of his work on "Rapid visualization of the vibration behaviour of electronic assemblies", which showed examples of the vibrations caused by different fixations of a circuit board.

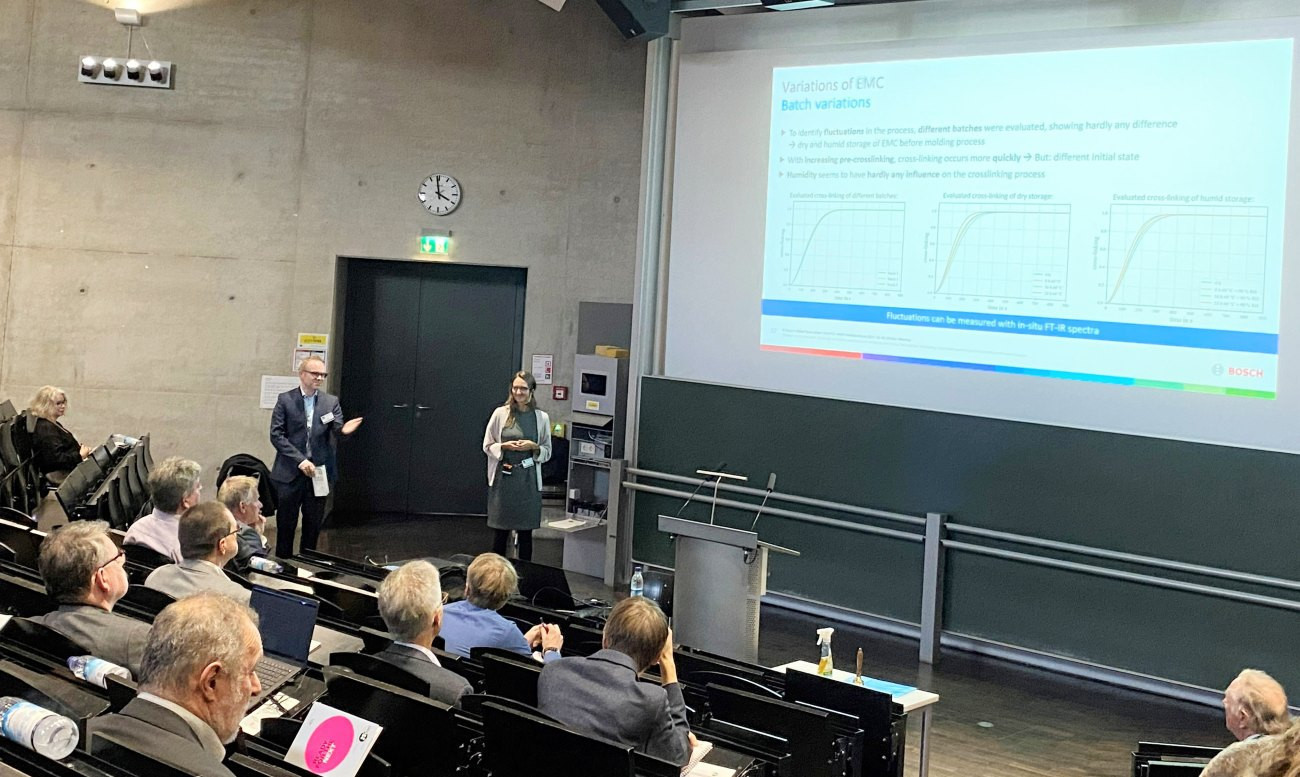

Corinna Niegisch during her presentation

Corinna Niegisch during her presentation

At the beginning of the Test and Qualification block, Corinna Niegisch, Robert Bosch GmbH, presented "In-situ investigations of the cross-linking process of epoxy resins to detect fluctuations in encapsulation processes of electronic components". While conventional measurement methods for the degree of crosslinking of molding materials at the beginning and end of the crosslinking process are often not accurate enough, FT-IR spectra have been successfully used as a method for detecting chemical changes. In the paper by Simon Kuttler, TU Berlin, he presented the results of his work on the "Analysis of the shear test of aluminum thick wire bonds". The simulation of shear tests at the bond points is used to assess the quality of connections with innovative aluminum-based thick wires. Among other things, the hardening and softening behavior of different types of wire during the shear test could be made visible. Steffen Wiljes from Fraunhofer ISIT gave an overview of the possibilities of "computed tomography in AVT" in the final presentation of the first day of the conference.

All speakers who contributed to the success of the conference with their technical contributions

All speakers who contributed to the success of the conference with their technical contributions

We would like to take this opportunity to thank all the speakers for contributing to the success of such conferences with their specialist contributions!

Networking is an important function of conferences. That is why it is a tradition and an important element for professional and network-building exchange among colleagues that we meet for an evening together. In recent years - with a few exceptions - this has taken place in the Augustiner and offers good opportunities to get into conversation with one another. We would like to thank the sponsors for their financial support of the evening.

On the second day of the conference, we started with presentations on materials and processes, where Adrian Bangerter from MicroContact AG began with a talk on "Fine Pitch Contacting". In particular, he addressed the challenges that test systems face in contacting increasingly miniaturized, sometimes flexible assemblies from a tolerance perspective. "Ultrasonic flip chip bonding with aluminium pillars for electrical contacting without under bump metallization" was the title of Silvia Braun's presentation at Fraunhofer ENAS. She discussed tests and investigations into flip-chip bonding on arrays of bumps that are as uniformly high as possible and achieve high reliability and shear forces. Daniel Lieske, AEMtec GmbH, spoke about "Wafer level solder bumping" and discussed the usual requirements, various methods for applying the bumps and practical results. Miniaturization drives, for example, use balls of 50µm, which poses challenges in terms of processes and materials. Developments at Koenen GmbH, whose Christian Ossmann reported on "Innovation in advanced packaging through 3D stencil printing", are also moving in the direction of miniaturization. Both very small depots and the mix of smaller and larger ones require special procedures when applying the pastes. In addition, tolerances are playing an increasingly important role with very small dimensions.

After the last exhibition and coffee break, there was the final reliability session, which was started by Markus Käß from BMW AG. His presentation "Simulation-based reliability assessment of electronic components on printed circuit boards" spanned the spectrum from DoE tests to the derivation of regression- and physically-based components and modeling to simulation-based service life prediction of components and assemblies. The "Numerical evaluation of thermal resistance as a reliability indicator for the solder joint degradation of discrete SiC MOSFETs" was the topic of the contribution by Borja Kilian, TU Berlin. Here, too, the focus was on the thermal connection of power components, which is weakened under the influence of alternating loads and can lead to failure. The last presentation was given by Jens Schneider, also from TU Berlin, under the title "Customized Design Libraries for Transmission Line Structures". This was aimed at those interested in high-frequency circuits who are familiar with the challenges of impedance-controlled design. The authors deal with the modeling of RF structures in PCB design.

In his closing remarks, 1st Chairman Martin Schneider-Ramelow spoke about the successful conference as well as a few details from the general meeting, provided information about upcoming IMAPS events and activities and thanked everyone for attending.

IMAPS General Assembly 2023

After the technical presentations on October 19, 2023, the members of IMAPS Deutschland e.V. met for the annual general meeting. In accordance with the articles of association, a report on the past year was given, both on the activities by the first chairman and on the financial situation of the association by the treasurer Ernst Eggelaar. Both also encouraged new colleagues to take an interest in the association. All members are asked to spread their positive experiences with IMAPS and to interest new colleagues.

Following these reports, the actions of the Executive Board for the previous year were approved. In 2023, the positions of Chairman and Secretary were up for re-election. In both cases, the incumbents Martin Schneider-Ramelow and Dirk Schade were re-elected for the next two years.

This was followed by an outlook on upcoming association activities and specialist conferences in the coming year. You can always find the most important ones here in our calendar of events. We would like to take this opportunity to draw your attention to the spring seminar, which is currently being planned for 20.2.2024 at Ingolstadt University of Applied Sciences and will focus on automotive electronics with the slogan "Electronics for the car of tomorrow". As soon as there is more detailed information and the program, you will find it in one of the next issues or on our website.

IMAPS Society Awards 2023

Prof. Jens MüllerTheIMAPS "umbrella organization" traditionally awards prizes to members who have made outstanding contributions to the association's international activities. In the various chapters around the world, there are many members who dedicate their time, energy and expertise to ensuring that our industry has a solid future. Each year, IMAPS honors particularly dedicated members of the Society who have done such remarkable work that they deserve the Society's award. This year, nine deserving individuals and one company received the awards, which publicly recognize each honoree's significant impact on the IMAPS Society and the packaging industry.

Prof. Jens MüllerTheIMAPS "umbrella organization" traditionally awards prizes to members who have made outstanding contributions to the association's international activities. In the various chapters around the world, there are many members who dedicate their time, energy and expertise to ensuring that our industry has a solid future. Each year, IMAPS honors particularly dedicated members of the Society who have done such remarkable work that they deserve the Society's award. This year, nine deserving individuals and one company received the awards, which publicly recognize each honoree's significant impact on the IMAPS Society and the packaging industry.

At the IMAPS Symposium, held October 2-5 in San Diego, our long-time IMAPS and Board member Prof. Jens Mueller was honored with the Sidney J. Stein International Award. The award is presented annually to an individual who has "... made a significant international technical contribution ... provided leadership in the microelectronics packaging industry ... participated in international IMAPS activities ... supported these activities to promote the electronic packaging industry ... at least 5 years membership in an international IMAPS chapter ... (IMAPS North America)". This clearly applies to Jens Müller. Congratulations on this!

Jens Müller received his diploma in electrical engineering in 1992 and his doctorate in 1997 from the Technical University of Ilmenau. From 1997 to 2005, he held a management position in development at Micro Systems Engineering GmbH Berg. His responsibilities included the research and development of medical implants (especially pacemakers) as well as general substrate and package development (e.g. LTCC, flex circuits, chip scale packaging).

In 2005, he returned to the Ilmenau University of Technology to set up the junior research group "Functionalized Peripherals". In July 2008, he was appointed full professor in the field of electronics technology. His research interest is in functional integration for ceramic-based system-in-packages considering aspects of harsh environmental use and high thermal/high frequency requirements with a strong focus on LTCC, LTCC/Si and LTCC/glass composite substrates. From 2012 to 2018 he was Director of the Institute for Micro and Nanotechnologies MacroNano® at his university and is currently Vice President for International Affairs and Transfer. He joined IMAPS Germany in 1992 and serves on the Board of Directors, of which he was 1st and 2nd Chairman between 2000 and 2010. In addition, he was organizer/co-organizer of various national and international IMAPS conferences and supported the SEMI Advanced Packaging Conference as technical program member for more than 13 years.

30 years of Fraunhofer IZM - a look back

The idea of founding the Fraunhofer Institute for Reliability and Microintegration IZM was born at the end of the 1980s. But how did it come about? Why was it so important to address the issues surrounding packaging?

Roll-to-roll production of polymer electronic circuitsThebasic idea came from Prof. Herbert Reichl, who took over the Chair of Microperipheric Technologies at the Technical University of Berlin in 1987. At that time, microelectronics was developing rapidly in Europe. Circuits were getting smaller and smaller. The package, on the other hand, tended to remain unchanged and was therefore usually extremely inefficient. This meant that more focus had to be placed on assembly and connection technology.

Roll-to-roll production of polymer electronic circuitsThebasic idea came from Prof. Herbert Reichl, who took over the Chair of Microperipheric Technologies at the Technical University of Berlin in 1987. At that time, microelectronics was developing rapidly in Europe. Circuits were getting smaller and smaller. The package, on the other hand, tended to remain unchanged and was therefore usually extremely inefficient. This meant that more focus had to be placed on assembly and connection technology.

In December 1993, a group of 21 scientists from the TU and HU Berlin and the Academy of Sciences in Chemnitz joined forces under the leadership of Herbert Reichl. The start of the Fraunhofer Research Institution for Reliability and Microintegration thus also marked an important milestone in the convergence of research from West and East Germany. The aim was to develop competitive assembly and connection technology for industry.

An important breakthrough was already achieved in the founding year: for the first time in Europe, the use of cost-effective polymer circuit boards for flip-chip assembly was tested, making chip production more efficient. The more space-intensive wire connection could be replaced by bump contacting. Just two years later, the institute put the first flip-chip assembly line in Europe into operation. Institute status followed shortly afterwards. A second application was quickly found, as pixel detectors, such as those used in particle accelerators at CERN, have several thousand contact pads. The flip-chip technology between the sensor element and ASIC was developed. This flagship soon attracted new customers, including small and medium-sized companies.

In 1998, the institute was expanded to include a branch office in Teltow, which is dedicated to polymer materials and composites. At the same time, various project groups were set up with the universities in Paderborn and Chemnitz. In 2002, a further branch of the institute was founded in Munich, which deals with roll-to-roll and 3D wafer technologies. Today, this is a completely independent institute.

An institute for reliability has always had to face new challenges. If we look at new areas of application for microelectronics, stretchable and flexible materials are increasingly being used. From 2003, the focus shifted to issues relating to the use of electronic elements in clothing. In 2005, the first communication system integrated into clothing was presented.

Jacket for a bicycle courier, developed by Fraunhofer IZM in cooperation with students at FHTW Berlin

Jacket for a bicycle courier, developed by Fraunhofer IZM in cooperation with students at FHTW Berlin

The next development steps took place in sectors such as automotive and industrial electronics, medical technology, ICT and the semiconductor industry. In 2010, the year Prof. Klaus-Dieter Lang took over the management of Fraunhofer IZM, the Dresden site, "All Silicon System Integration Dresden" (ASSID), was founded. A micro camera, which is not much larger than a coarsely ground grain of salt and therefore fits into an endoscope tip, was developed here more than 10 years ago.

After 20 years of continuous growth, the institute opened the Start-A-Factory in 2017, a unique prototyping line specifically designed for hardware start-ups. At the same time, the institute dedicated itself to the topic of sustainability through the major project "Green ICT", which was designed to improve the sustainability of information and communication technology. This illustrates the ongoing commitment to environmental aspects and sustainability. Today, under the leadership of Prof. Martin Schneider-Ramelow, over 400 employees are tackling new challenges in areas such as quantum electronics, 6G, zero-power electronics and high-performance systems for exceptional applications and harsh environmental conditions.

Fraunhofer IZM can look back on a 30-year success story in the research field of packaging technology, which was celebrated on September 28, 2023 in Berlin with a symposium entitled "Crossing Frontiers in Microelectronics" (for more details, see the PLUS editorial article on page 1605).

(Text: based on a summary by N. Groll and S. Thoma)

Institute Director Prof. Martin Schneider-Ramelow (with shield) together with his predecessors, Prof. Klaus- Dieter Lang (left) and Prof. Herbert Reichl

Institute Director Prof. Martin Schneider-Ramelow (with shield) together with his predecessors, Prof. Klaus- Dieter Lang (left) and Prof. Herbert Reichl

Calendar of events

|

Place |

Period |

Event name |

Organizer |

|

Ingolstadt |

February 20, 2024 |

Spring seminar |

IMAPS D |

|

Fellbach |

March 05 / 06, 2024 |

EBL 2024 |

DVS/GMM |

|

Fountain Hills |

March 18 - 21, 2024 |

Device Packaging 2024 |

IMAPS USA |

|

Toyama |

April 17 - 20, 2024 |

ICEP 2024 |

IMAPS, JIEP, IEEE EPS Japan |

|

Landshut |

April 18, 2024 |

Symposium Electronics and System Integration (ESI) |

HS Landshut |

IMAPS Germany - Your association for packaging and packaging technology

IMAPS Germany, part of the 'International Microelectronics and Packaging Society' (IMAPS), has been the forum in Germany for all those involved in microelectronics and packaging technology since 1973. With almost 300 members, we essentially pursue three important goals:

- we connect science and practice

- we ensure the exchange of information among our members and

- we represent the position of our members in international committees.

Imprint

IMAPS Germany e. V.

Kleingrötzing 1, D-84494 Neumarkt-St. Veit

1st Chairman: Prof. Dr.-Ing. Martin Schneider-Ramelow, Director of the Fraunhofer Institute for Reliability and Microintegration (IZM),

Treasurer

(for questions about membership and contributions):

Ernst G. M. Eggelaar,

You can find detailed contact information for the board members at www.imaps.de

(Board of Directors)