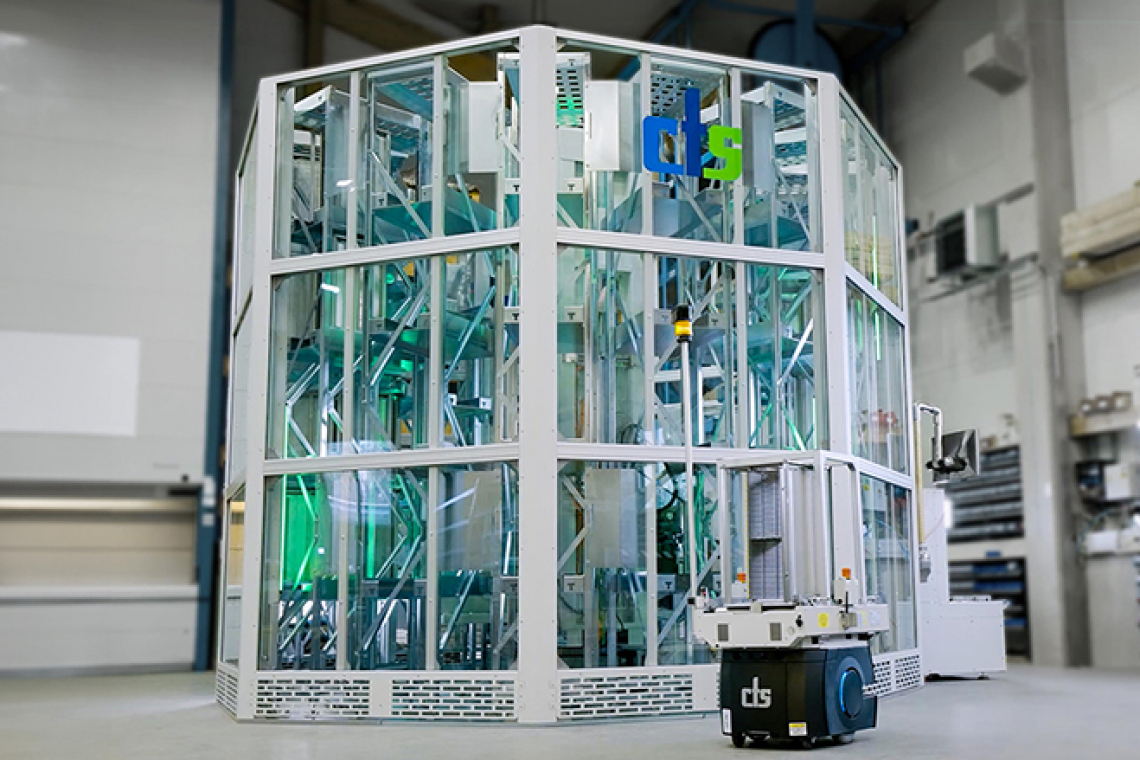

The intralogistics and automation specialist cts GmbH is expanding the functional scope of its successful Smart In-Production Warehouse for the electronics and automotive industry: both the Smart Warehouse and the smaller Mini Smart Warehouse variant can now mix and automatically store and retrieve KLT boxes and tray stacks from various manufacturers in addition to PCB magazines.

Intelligent and space-saving storage systems from cts have been successfully used for PCBs across all industries since 2020. Fully automated on request, both PCB magazines and standardized small load carriers, so-called KLT boxes, as well as tray stacks can now be temporarily stored in a mixed manner - either in the same area or in an additional, separate area in the warehouse, but always in a space-saving and efficient manner close to the production lines.

Intelligent and space-saving storage systems from cts have been successfully used for PCBs across all industries since 2020. Fully automated on request, both PCB magazines and standardized small load carriers, so-called KLT boxes, as well as tray stacks can now be temporarily stored in a mixed manner - either in the same area or in an additional, separate area in the warehouse, but always in a space-saving and efficient manner close to the production lines.

Mixed storage has many advantages for the customer. In addition to the PCBs, consumables such as solder paste or cleaning fluid can now also be stored in a space-saving manner and integrated into the fully automated intralogistics system. Both the PCB magazines and the KLT boxes can be tracked precisely - an important basis for seamless material flow monitoring, for example by an ERP system or in the SAP world."

"cts - more than automation"

Founded in 2006, cts GmbH, Burgkirchen, offers customers a complete range of services for process and production automation. More than 350 employees develop innovative solutions at several locations in Europe, Singapore and, in future, the USA. The comprehensive range of services offered by the established system integrator from southern Bavaria includes feasibility studies, conceptual design, planning, implementation, maintenance and servicing of running systems and plants.