The electrolytes require a certain working temperature, which can be exceeded during continuous operation due to the generation of Joule heat, heat input from the ambient temperature or exothermic reactions. In coating processes with high current densities, a high thermal output is converted into Joule heat in the bath. This heat input must be cooled continuously and reliably. Tubular coils and/or external plate heat exchangers can be used for cooling.

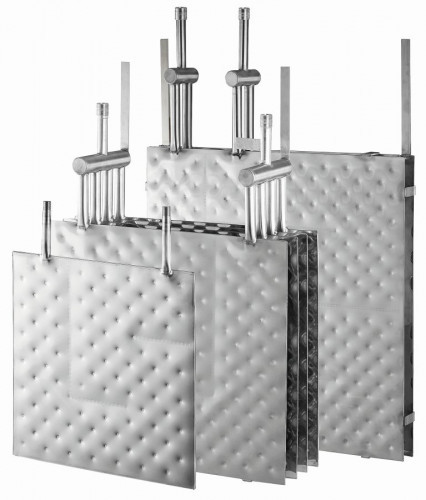

Mazurczak offers space-saving and energy-efficient heat exchangers for cooling process baths in electroplating. Four different stainless steels (1.4301, 1.4404, 1.4571 and 1.4539) and titanium 3.7035/grade 2 are available as metallic materials. The version with a metallic base body and a fluoropolymer coating is used if the metallic materials are not chemically resistant.

Efficient and precise calculation of the cooling requirement and adaptation to the available space

A computer-aided cooling requirement calculation is used to efficiently calculate the required cooling capacity. Using heat exchanger software developed in-house, the SYNOTHERM heat exchanger is designed accordingly and adapted to the available space in the container. Each heat exchanger is unique. Even in the most difficult installation situations, the optimum installation variant is realized through variable dimensions, materials and various connection options.

Properties of SYNOTHERM compared to other heat exchanger designs

The SYNOTHERM requires considerably less maintenance than other heat exchanger designs. The flat and smooth surface can be cleaned quickly and easily. Falling parts or sediment cannot be deposited on the heat exchanger body or get caught in it.

Screwed or soldered external heat exchangers have two circuits. This means that the electrolyte and the cooling medium flow through the heat exchanger. The electrolyte can lead to rapid clogging and blockage of the heat exchanger. The external heat exchangers must be dismantled, cleaned and reassembled. The SYNOTHERM heat exchangers are only flowed through by the cooling medium and therefore cannot become clogged or blocked by the electrolyte.

Large heat exchanger surface area with a small construction volume

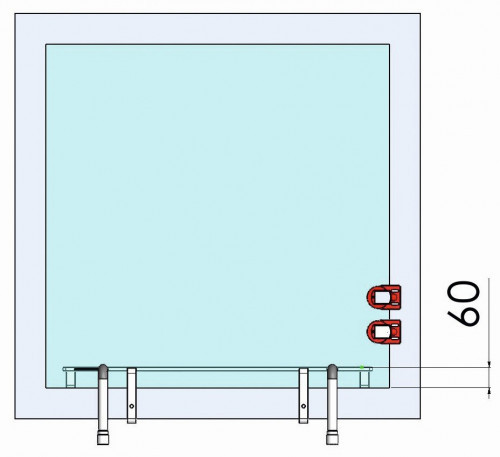

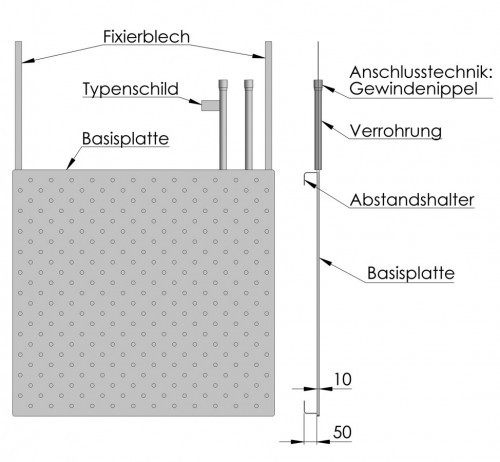

Components, structure and space requirements of a heat exchangerIn addition,the heat exchangers have a high surface density. This means that a large heat exchanger surface area can be provided in relation to the required construction volume. The total construction depth of the heat exchanger is only 60 mm (10 mm base plate + 50 mm spacer to the tank wall).

Components, structure and space requirements of a heat exchangerIn addition,the heat exchangers have a high surface density. This means that a large heat exchanger surface area can be provided in relation to the required construction volume. The total construction depth of the heat exchanger is only 60 mm (10 mm base plate + 50 mm spacer to the tank wall).

Typical applications for metallic heat exchangers for cooling are

- Nickel electrolytes

- Anodizing baths

- Electropolishing baths

- Chrome electrolytes

- Acid zinc electrolytes

- Alkaline zinc and zinc-nickel electrolytes

- Acid zinc baths

- Acid copper electrolytes

Successful use for cooling a black chrome bath

Süss Oberflächentechnik GmbH coats customer components in its anodizing and electroplating plants. The "black chrome" process must be cooled to a temperature of 19 °C. In 2019, a heat exchanger made of titanium 3.7035/Grade 2 was designed and delivered. Water with a flow temperature of 10 °C is used as the heat exchanger medium. As the following feedback from the customer shows, the SYNOTHERM meets all requirements to the fullest satisfaction: "The "black chrome" coating process takes place at very high current densities, so that a high thermal output is converted in the bath. This heat must be dissipated reliably. In the past, heat exchangers made of PVDF were used for this purpose, but they had to be very large due to their poor thermal conductivity and high wall thicknesses. By opting for a plate heat exchanger from Mazurczak made of titanium sheet, the installation space in the bath could be significantly reduced. As a result, the bath volume was reduced by 25 % during the conversion of the system. This was also accompanied by a reduction in the active bath volume relevant for official approval under the Hazardous Incident Ordinance. "We have found that the cooling capacity is completely sufficient despite the significantly reduced installation space. The heat exchanger has been in operation for three years without any problems," says Jens Mohr, Managing Partner of Süss Oberflächentechnik GmbH.

Pictures: Mazurczak