Mazurczak GmbH is the full-service provider for heating, cooling and controlling aggressive liquids in the field of electroplating and surface technology. In addition to the well-known Rotkappe safety bath heaters with integrated anti-fire system, the company will also be presenting the new electric heating coils and new Synotherm heat exchangers.

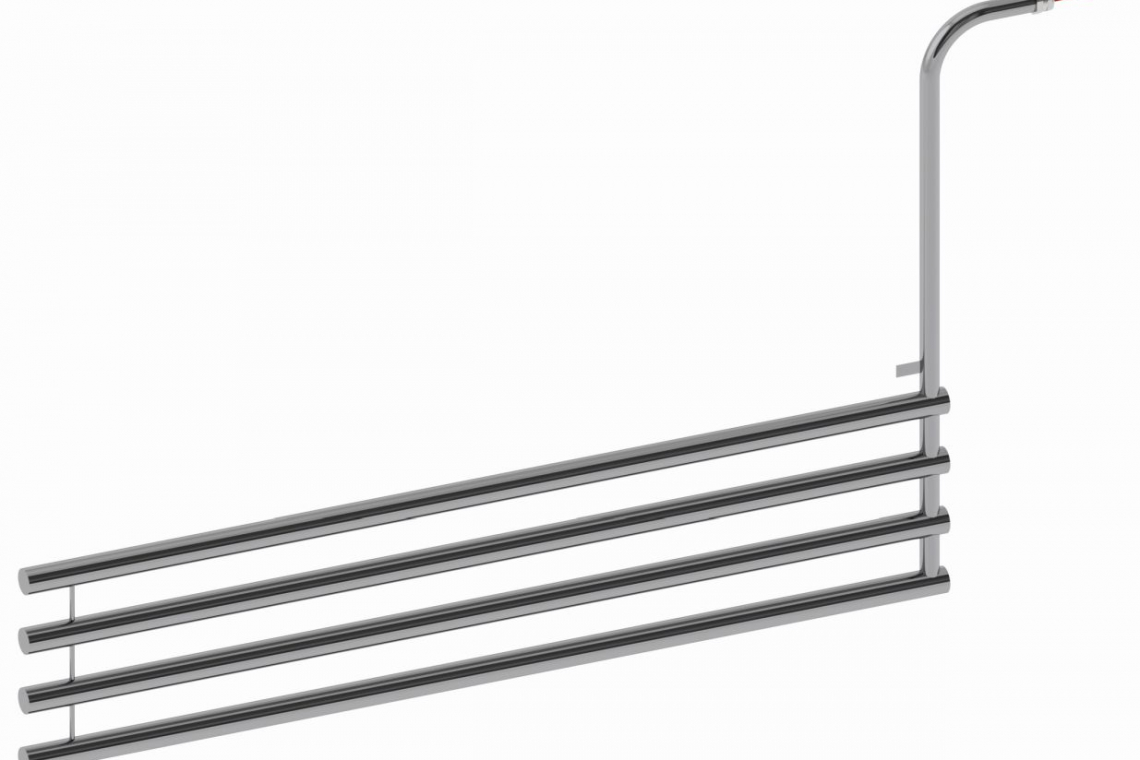

Electric heating registers for use in systems and containers

Electric heating registers for use in systems and containers

The heating registers are designed as direct heating for use in systems and containers according to individual customer requirements.

They are characterized by a high power density. This means that a large heating capacity can be provided in relation to the required installation volume. The dimensions of the heating elements can be easily adapted to the available space in the tank (wall or floor). The materials available are stainless steel 1.4571/AISI316Ti, steel S355J2H or titanium 3.7035.

The compact arrangement is carried out on site using brackets in the tank. The individual heating elements can be easily removed for cleaning and maintenance. Lengths of up to 3500 mm with a maximum output of up to 20 kW can be realized. By implementing a high heating capacity, the wiring and installation costs are significantly lower compared to other heating concepts.

Heating and cooling aggressive media

Our new plastic heat exchangers are made of solid plastic and are suitable for heating and cooling extremely aggressive media in which metallic plate heat exchangers cannot be used. Plastic heat exchangers have PFA tubes which are wound in a comb construction made of PP or PVDF. The combs were designed with a view to a material-saving lightweight construction, so that at the same time a sufficient flow of process medium is ensured.

Our new plastic heat exchangers are made of solid plastic and are suitable for heating and cooling extremely aggressive media in which metallic plate heat exchangers cannot be used. Plastic heat exchangers have PFA tubes which are wound in a comb construction made of PP or PVDF. The combs were designed with a view to a material-saving lightweight construction, so that at the same time a sufficient flow of process medium is ensured.

Less maintenance required for heat exchangers in phosphating processes

Thanks to the special coating, the Synotherm plate heat exchanger has excellent non-stick properties. The non-stick properties allow the incrustation to be removed quickly and easily. The coated heat exchanger is cleaned by hand using a plastic spatula directly in the container.