New times call for new approaches. In an electroplating plant, there are a number of levers that can be used to make processes even more efficient and save energy:

Expand automation

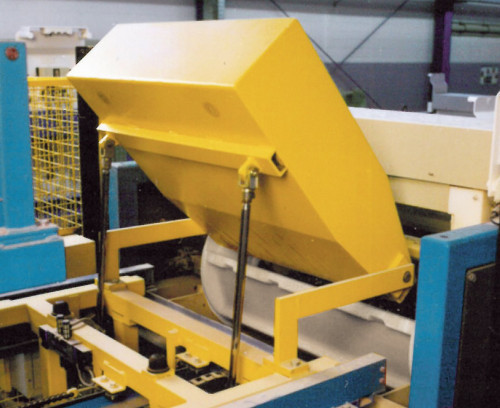

In times of a shortage of skilled workers, it is important to find ways to relieve the burden on staff - for example, by automating activities that were previously carried out manually. The upstream and downstream activities in particular are predestined for this: Based on the GALVAROB automatic loading and unloading station, the charging of the goods, the loading of the system, the loading and unloading of the drum can be automated in a time-efficient manner.

Saving energy through modernization

It's great if the dryers you've been using for many years are still working. But do they do so efficiently? It is worth taking a close look at old dryers and replacing them with modern drying systems such as the GALVADRY. Its optimized drying process saves energy, reduces drying time and improves quality. Thanks to the energy savings and possible state subsidies, the investment pays for itself in a short time.

Saving resources with durable designs

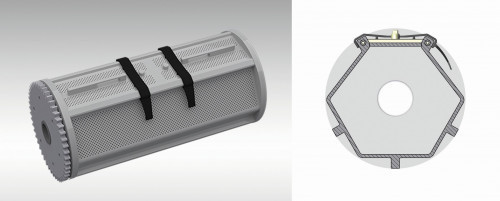

Galvanizing drums and units are exposed to immense stress from aggressive bath media. To withstand this, particularly durable designs are welcome - such as the mechanically butt-welded electroplating drums GALVA-XL, GALVA-E or GALVA-HP. Low-drag drive solutions also ensure that bath media does not enter the drive motor, which extends the service life of the barrel unit.

Saving energy through innovation

Established standards can also be optimized in exhaust air technology. For example, through more efficient droplet separation. Thanks to its helical flow channels, the ZYKLOTOP droplet separator achieves a separation efficiency of up to 99 % and separates even the tiniest droplets of just 24 µm in diameter. With a pressure loss of just 55 Pa, around 20 % extraction capacity can be saved compared to conventional droplet separators.

Pictures: Tscherwitschke