Over 1,400 exhibitors from 45 countries presented their products for the development, production and testing of electronics at 'productronica 2023' and 'SEMICON Europa', which took place at the same time. In issue 12/23, we already listed a number of innovations and program items that we saw. In this issue, we list more - and report on important presentations at the world's leading trade fair.

Forum PCB & EMS Marketplace offered information on current topics

Dr. Mareike Haaß provided information on the EMS marketDr. Mareike Haaß, in4ma, used current market data to provide information on trends and developments in the European and German EMS industry. In addition to detailed sales figures, the rankings for Europe and the DACH region were also presented. She also addressed the ongoing consolidation of the market. There are just over 2,200 EMS companies in Europe. Of these, 80% have a turnover of less than €10 million and a market share of 11.2%. Not all of these companies will survive the next ten years. The current challenges often include high material inventories with lower incoming orders or call-offs. Opportunities are presented by the continuing growth of the overall electronics market. Growth rates of between 6% and 7% are expected for the entire EMS business in Europe over the next few years.gk-

Dr. Mareike Haaß provided information on the EMS marketDr. Mareike Haaß, in4ma, used current market data to provide information on trends and developments in the European and German EMS industry. In addition to detailed sales figures, the rankings for Europe and the DACH region were also presented. She also addressed the ongoing consolidation of the market. There are just over 2,200 EMS companies in Europe. Of these, 80% have a turnover of less than €10 million and a market share of 11.2%. Not all of these companies will survive the next ten years. The current challenges often include high material inventories with lower incoming orders or call-offs. Opportunities are presented by the continuing growth of the overall electronics market. Growth rates of between 6% and 7% are expected for the entire EMS business in Europe over the next few years.gk-

Panel discussion 'The EMS industry in the electronics ecosystem'

In order to maintain the international competitiveness of the European industry, a semiconductor and electronics ecosystem is needed in Europe. PCB and electronics manufacturing are enablers for the further processing of semiconductor chips. The role of the EMS industry in the electronics ecosystem and what this industry can do after the Chip Act was discussed by Michael Velmeden, cms electronics gmbh, Markus Aschenbrenner, Zollner Elektronik AG, Carsten Ellermeier, Prettl Electronics GmbH, and Victoria Rawinski, Rawinski GmbH, under the moderation of Johann Wiesböck, Elektronikevangelist. Their statements can be summarized as follows: Electronics is systemically relevant and its entire value chain must be competitive if it is to remain here and deindustrialization is to be prevented. The industry needs to publicize this more clearly and in more diverse ways. Although electronics production is currently weakening, it will grow in the long term as a result of megatrends. It is therefore important to stabilize it now and to take weaknesses and pent-up demand - such as in PCB technology - into account. Processes, not products, should be promoted. Economic crises are outsourcing drivers and therefore beneficial for the EMS sector. The opportunities must be exploited. This requires new and further qualified employees as well as investments. Politicians should support this with appropriate framework conditions, including an energy price cap and investment grants for the elimination of weak points.-gk-

Panel discussion: More women for electronics

One of the most exciting panel discussions at the trade fair was organized by the Organic and Printed Electronics Association (OE-A) and the German Engineering Federation (VDMA). The panel discussed the question "How can women be encouraged to enter the electronics industry?" - a key issue in times of a shortage of skilled workers. Given the data available on the labor force participation of men and women, new, high-quality workers can practically only be recruited from among the latter (see PLUS 5/2023, p. 640-652). Accordingly, the topic is of enormous importance, which OE-A and VDMA have recognized. The high-caliber panel discussion consisted of four strong women: Anna Laureen Lauven (Plasmatreat), Miriam Seidl (F&S Bondtec), Dr. Muriel Thomas (Heraeus Printed Electronics) and Helena van de Ven (ASMPT). Dr. Sandra Engle, VDMA Eletronics, Micro and New Energy Technologies - and also a member of the PLUS Advisory Board - also took on the role of moderator. She began by stating the hard facts: In the field of mechanical engineering for the electronics industry, the proportion of women among working specialists is less than 6% - and among students, i.e. future specialists, less than 10%. [When asked about their own experiences, the panelists talked about their paths into electronics. Sandra Engle did not shy away from directly addressing the often criticized 'bad image' of electrical engineering, which many describe as too male-dominated and inaccessible. Helena van de Ven disagreed ("Electronics are very attractive for everyone."), but Miriam Seidl also recognized a problem with the very traditional external perception of electrical engineering. There is an urgent need for social change: "We need a shift in society." This is where women themselves are called upon, as all four panelists confirmed. Helena van de Venrecommended improving networking skills among women. With pay known to lag behind men, more self-confidence is needed in negotiations, Anna Laureen Lauven emphatically agreed: "Be more pushy, go out of your comfort zone." She encouraged women who have already gained a foothold in the industry to actively take on a mentoring role for up-and-coming young women. Muriel Thomas advised women to venture more onto the 'international stage', i.e. not to shy away from jobs abroad. But the women also had advice for the industry itself. According to Muriel Thomas, companies should approach young women more and invite them to events. Miriam Seidl criticized the often imprecise job descriptions for skilled workers. They need to state more clearly what awaits them, as women in particular are very specific about the requirements and are put off - and hide their light under a bushel.

Unfortunately, one aspect was neglected that should not be ignored: How can women better reconcile motherhood and a job? And how can women with the best qualifications be encouraged to return to work after maternity leave - without losing out or being disadvantaged? Anna Laureen Lauven was the only participant to address this topic, but was unable to come up with a solution. No wonder, as it is not just the industry that is called upon to act here, but society as a whole. It would have been desirable to discuss this aspect in more depth. But apart from that, it was a lively and courageous discussion - also because Dr. Sandra Engle addressed relevant topics in a targeted manner.-mh-

[*] Cf. the interview with Lucie Bangert on p. 90, who reports on how she is the only woman in the field of electronics to complete her Bachelor's degree, while her fellow students have dropped out - many of them because the low proportion of women is a deterrent.

Panel discussion between Dr. Sandra Engle (moderator), Anna Laureen Lauven, Miriam Seidl, Muriel Thomas and Helena van de Ven (from left to right)

Panel discussion between Dr. Sandra Engle (moderator), Anna Laureen Lauven, Miriam Seidl, Muriel Thomas and Helena van de Ven (from left to right)

IPC presentation: 'Factory of the Future Vision - An SME's Perspective'

Naim Kapadia (Grinsty Rail), Thomas Marktscheffel (ASMPT SMT Solutions) and Markus Scheid (Scheid IT) during the IPC presentation (from left to right)At a rather inconspicuous, dark stand of the American Association Connecting Electronics Industries (IPC) in Hall A4, a surprisingly large audience gathered to learn more about the vision of a smart factory. The focus was on the open industry standard IPC-2591, which supports IPC-CFX (Connected Factory Exchange), an IIoT technology standard for the assembly industry and the basis for Industry 4.0 and smart digital factory solutions for optimizing production processes. IPC-2591 standardizes the exchange of information between manufacturing processes and associated host systems for assembly production - automated, semi-automated and manual. A lot has happened since the original IPC-2591 version from 2019, with the latest version 1.6 appearing in spring 2023. So it's time to promote the protocol again at 'productronica'. Introduced by Michael Ford (Aegis Software), Naim Kapadia (Grinsty Rail), Thomas Marktscheffel (ASMPT) and Markus Scheid (Scheid IT) reported on the positive experiences they have had with the standard and the enormous advantages they expect: a smart factory whose individual components communicate with each other without barriers (plug & play principle) - in close interaction with the Hermes standard. The companies Rehm, ASMPT, TRI, Saki, Vitrox, Robotas, Grinsty Rail, Keller Industries, Omron and others have already signed up. Of course, the IPC also wants to make the standard attractive to other companies in Europe. The audience showed that there is a great deal of interest. However, there was no in-depth, even critical discussion.mh-

Naim Kapadia (Grinsty Rail), Thomas Marktscheffel (ASMPT SMT Solutions) and Markus Scheid (Scheid IT) during the IPC presentation (from left to right)At a rather inconspicuous, dark stand of the American Association Connecting Electronics Industries (IPC) in Hall A4, a surprisingly large audience gathered to learn more about the vision of a smart factory. The focus was on the open industry standard IPC-2591, which supports IPC-CFX (Connected Factory Exchange), an IIoT technology standard for the assembly industry and the basis for Industry 4.0 and smart digital factory solutions for optimizing production processes. IPC-2591 standardizes the exchange of information between manufacturing processes and associated host systems for assembly production - automated, semi-automated and manual. A lot has happened since the original IPC-2591 version from 2019, with the latest version 1.6 appearing in spring 2023. So it's time to promote the protocol again at 'productronica'. Introduced by Michael Ford (Aegis Software), Naim Kapadia (Grinsty Rail), Thomas Marktscheffel (ASMPT) and Markus Scheid (Scheid IT) reported on the positive experiences they have had with the standard and the enormous advantages they expect: a smart factory whose individual components communicate with each other without barriers (plug & play principle) - in close interaction with the Hermes standard. The companies Rehm, ASMPT, TRI, Saki, Vitrox, Robotas, Grinsty Rail, Keller Industries, Omron and others have already signed up. Of course, the IPC also wants to make the standard attractive to other companies in Europe. The audience showed that there is a great deal of interest. However, there was no in-depth, even critical discussion.mh-

www.ipc.org/TOC/IPC-2591-Version-1.6-TOC.pdf

In his presentation 'Catalyzing a Brighter Future for the Chip Industry' at the SEMICON discussion forum 'ITF towards NETZERO', Frederic Godemel, Schneider Electric, promoted the concept of building a more sustainable industry with lowerCO2 emissions overall by expanding strictly sustainable production - the famous energy paradox. However, Godemel's presentation only scratched the surface; we had a more in-depth reflection on this in our interview with Schneider Electric (PLUS 4/2023). However, Goedemel also emphasized the political and economic dimension of expanding European chip factories in order to reduce dependencies.

In his presentation 'Catalyzing a Brighter Future for the Chip Industry' at the SEMICON discussion forum 'ITF towards NETZERO', Frederic Godemel, Schneider Electric, promoted the concept of building a more sustainable industry with lowerCO2 emissions overall by expanding strictly sustainable production - the famous energy paradox. However, Godemel's presentation only scratched the surface; we had a more in-depth reflection on this in our interview with Schneider Electric (PLUS 4/2023). However, Goedemel also emphasized the political and economic dimension of expanding European chip factories in order to reduce dependencies.Further trade fair innovations

Panasonic Factory Solutions Europe presented its range of SMT production systems. Among other things, visitors were able to see the new NPM G series in action. It combines AI and automation to respond immediately to changes in customer supply and demand through continuous, autonomous updates. It offers flexibility and customizable options to meet production requirements and make autonomous factories a reality. The NPM G-Series combines four technologies. It includes:

- NPM-GP/L screen printing machine with automatic print process functions that can automatically make changes to the production line

- NPM-GH modular placer with industry-leading assembly accuracy

- Auto Setting Feeder (ASF) for automatic feeding of components, an industry first. The ASF can automatically remove the cover from surface mount component strips from 4mm to 104mm wide

- The APC-5M system for Adaptive Process Control (APC) monitors the correct placement of components based on the solder print position. In the event of misalignment, it provides feedback to the stencil printer.-gk-

Göpel electronic was delighted that its FlashFOX production programmer for embedded in-system programming was awarded second place in the 'Inspection & Quality' cluster of the productronica innovation award. The outstanding connectivity and innovative licensing options of FlashFOX open up completely new, cost-efficient application scenarios. With its scalability, adaptability and first-class performance parameters, it is a next-generation stand-alone programmer. In addition to the FlashFOX highlight, the trade fair also offered insights into inspection solutions and embedded JTAG solutions from Göpel electronic.

The highlight at the Göpel stand was the FlashFOX production programmer

The highlight at the Göpel stand was the FlashFOX production programmer

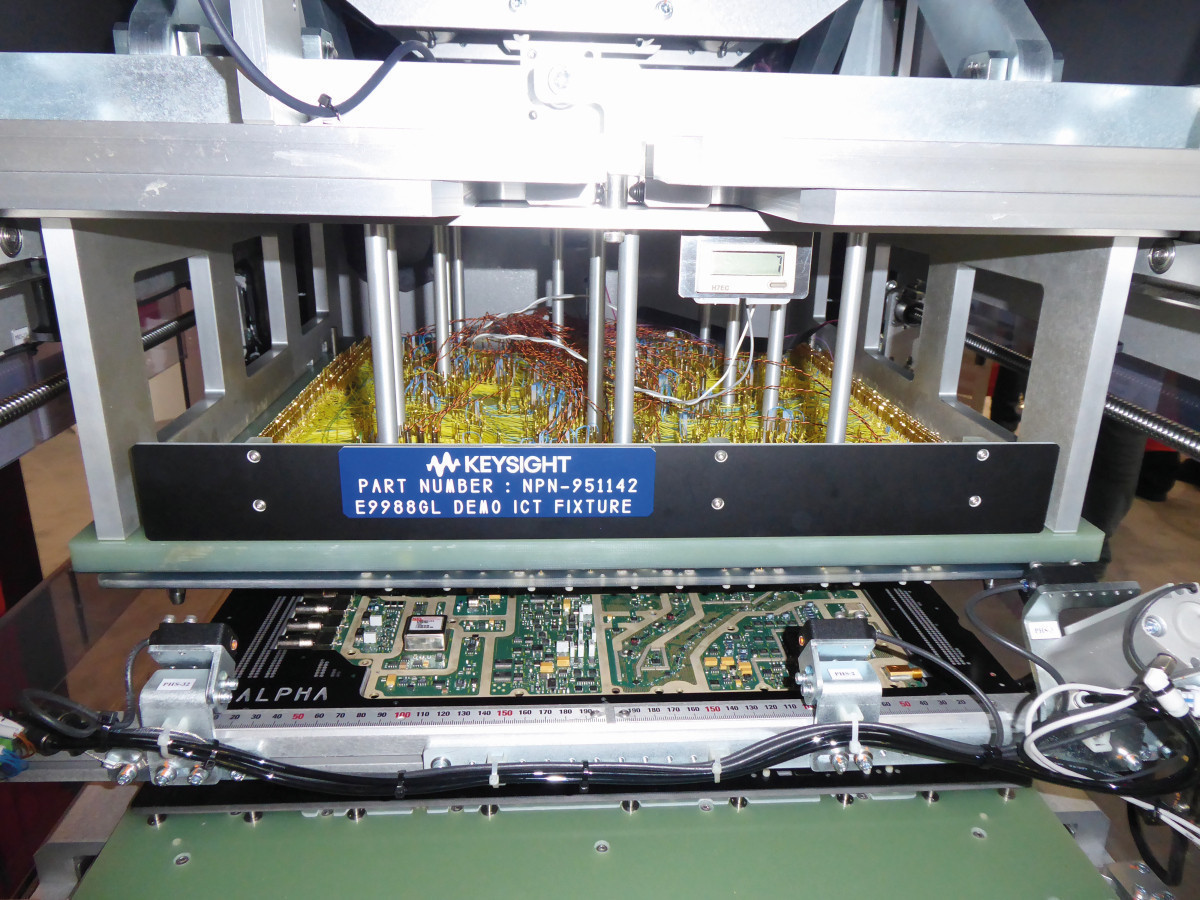

Keysight Technologies Germany presented the new Keysight i3070 Series 7i inline in-circuit test system, which offers increased capacity and throughput. The award-winning ICT system increases capacity up to 5760 nodes in a slim inline footprint to meet complex test requirements and enable processing of larger PCBs. It offers the following benefits:

- Accelerated short circuit testing (by 50% compared to conventional methods)

- Double the number of test nodes while maintaining a compact footprint

- Integrated testing for supercapacitors up to 100F

- Proven Keysight short-wire fixturing.-gk-

Premiere of the new ICT Keysight i3070 Series 7i

Premiere of the new ICT Keysight i3070 Series 7i

Omron pulled off a surprise with the presentation of the new VP-01G 3D SPIsystemOmron presented the VT-S1080 (3D-AOI), VT-X750 (High Speed 3D-CT AXI) and the new VP-01G (3D-SPI) inspection systems. With the latter, Omron has expanded its SPI portfolio.

Omron pulled off a surprise with the presentation of the new VP-01G 3D SPIsystemOmron presented the VT-S1080 (3D-AOI), VT-X750 (High Speed 3D-CT AXI) and the new VP-01G (3D-SPI) inspection systems. With the latter, Omron has expanded its SPI portfolio.

Key features of the VP-01G 3D-SPI include its unique ring light, 3D projectors and Z-axis autofocus. Using a 360-degree ring light source, an outline of the solder paste can be extracted, enabling zero slip with bridging. This inspection method isolates the solder paste on a PCB and performs three-dimensional measurements. It enables an optimal combination of cycle time and capabilities thanks to its multi-switchable resolution for high-speed production, offering reliable inspection and a top price-performance ratio.

Designed for maximum system performance and high productivity, the AOI generation S1080 Series II is the first with a 25M pixel camera and new SW features. The innovative AI programming enables flexible production and reduced labor costs.

Other Omron trade fair highlights included innovations in the field of automation, including systems for mobile and collaborative robotics, AI and machine vision. One example is Omron's In-Time Mobile Manipulator (MoMA) transfer solution.

The Asys Group presented several innovations in Munich, first and foremost the 'VEGO AES 03 Speed' line loader, which can independently feed stacks of PCBs to the SMD line. With a mobile transport robot (AMR), the material exchange of the corresponding magazines is automated for both assembled assemblies and unassembled PCBs, which relieves employees of physical work and saves personnel resources. Compared to conventional stack loaders, the 'AES 03 Speed' makes batches - the packaging units of the PCB stacks - fully traceable. They are stored separately in the magazine to prevent mixing. Before being placed in the stacking magazine, the batch code is scanned and assigned to a specific magazine slot. The batch code is transmitted to the downstream laser marking system upon removal and linked to the product code. This ensures the traceability of an assembly back to the PCB manufacturer, which is important in the automotive sector, for example.

Another innovation on show was the 'HERMES Assistant', which bundles line-related tasks centrally at a PC workstation. It ensures supplier-independent machine-to-machine communication (M-to-M) and convenient line changeover to the HERMES standard without major programming effort with simple mouse clicks. The storage capacity for product programs is unlimited.

The 'Performance Monitor' received a 'productronica' award. It provides a single OEE display of an SMD line and, in conjunction with the 'PULSE PRO Suite', displays the number and duration of faults in an overview. An interface extension to the customer's ERP system also enables the target time to be called up and displayed.

Waygate Technologies presented the new X-ray system 'Phönix nanome|x neo', which makes it possible to see even more details

Waygate Technologies presented the new X-ray system 'Phönix nanome|x neo', which makes it possible to see even more details

The EKRA innovations aroused particular interest. Managing Director Markus Albrecht took the time to explain EKRA's A.I.-based pressure inspection system, which enables autonomous printing processes in fuel cell production. The evaluation of processes such as the pressure of sealing structures or the coating of the so-called flow field in the inline process is controlled and optimized by a specifically trained artificial intelligence (AI). Dr. Sebastian Tepner, Product Manager at EKRA, explained in more detail how machine learning is used to train the AI to derive information on defects and anomalies from 2D images and to detect their three-dimensional characteristics on a bipolar plate - the core element of every fuel cell. Tepner also gave us the result, a bipolar plate manufactured using K I-optimized processes. It was exciting to be able to understand the real use of K .I. in production, especially as Albrecht and Tepner took plenty of time to explain the innovation to us.

Dr. Sebastian Tepner explains the K.I.-based pressure inspection system from EKRA

Dr. Sebastian Tepner explains the K.I.-based pressure inspection system from EKRA

"Let the sunshine in": Schmoll Maschinen from Rödermark/Ober- Roden shone with a new stand concept

"Let the sunshine in": Schmoll Maschinen from Rödermark/Ober- Roden shone with a new stand concept

The next 'productronica' in Munich will take place from November 18 to 21, 2025 -red-