SMTconnect in the Nuremberg exhibition halls was attended by both long-standing and several new exhibitors. Visitors used the trade fair for networking and technical discussions with the aim of further developing electronics production.

Around 8,400 visitors were able to find out about innovations and products along the entire electronics manufacturing value chain. In line with the motto 'Driving Manufacturing Forward', this year's SMTconnect highlights were sustainability, obsolescence management and AI in electronics production. Many discussions between the almost 230 exhibiting companies and partners and the visitors reflected the current mood. And the trade fair itself was also frequently discussed.

"For my team and I, SMTconnect has been a fixed date in the calendar for years," said Sandra Paggen-Breu, Managing Director of Paggen Werkzeugtechnik, who has been a permanent member of the exhibitor community for 25 years. "We look forward to the electronics industry's class reunion every year and always bring exciting projects home with us."

"SMTconnect is my absolute favorite trade fair," confirms Stefan Janssen, Managing Director of Fuji Europe. "I've been attending it for almost 30 years. We get direct feedback on our products from customers here - that's incredibly valuable for us. We look forward to exchanging ideas with all the other market players at this industry meeting. Here we get an optimal market overview and learn all about the latest trends and developments.

Supporting programs in all three halls - the industry is optimistic

The forum program with specialist lectures, panel discussions and product presentations once again offered a wide range of information this year. Dr. Sandra Engle, VDMA, and Volker Pape, VDMA and Viscom, gave a market outlook for the electronics machinery industry on the first day of the trade fair. The industry is optimistic. According to a survey of members of the VDMA trade association EMINT (Electronics Micro and New Energy Production Technologies), 46% of the companies surveyed rate their business performance to date as better than in the same period last year and more see opportunities for growth in revenue. For 2023, 24% of companies report stagnation. This figure falls by 13% for 2024. For 2023, 1% are forecasting growth of 0 - 5%, with this figure rising to 21% for 2024. 43% of companies see growth of 5 - 10% for 2023. The positive outlook is largely due to easing trends in upstream supply chains since June 2022. Bottlenecks have eased noticeably, particularly in the area of electrical engineering/electronic component supplies. However, from the perspective of electronics machinery manufacturers, supply bottlenecks for electronic components remain. The focus remains on staffing levels and the need for skilled workers: 30% of companies consider the shortage of skilled workers to be serious. 55% of productronics companies are aiming to increase their workforce, while around 45% are not planning any changes. High prices for energy, raw materials and primary products are having a noticeable negative impact on 74% of companies. 65% of electronics machinery manufacturers rate the price situation of purchased primary products as poor.

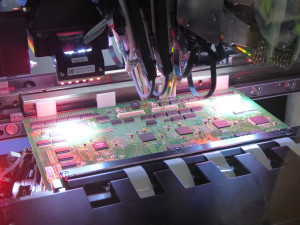

As in previous years, the 'Future Packaging' production line, which was once again organized by the Fraunhofer Institute for Reliability and Microintegration (IZM), offered deeper insights into electronics production. The focus was on 'Trust the Line - Competitiveness through Trust, Sustainable Tool and Supply Chain'.

Ulf Oestermann (l.), Fraunhofer IZM, gave a guided tour of the 'Future Packaging' production line and also gave a forum presentation on 'Trust the Line - Competitiveness through Trust, Sustainable Tool and Supply Chain'

Ulf Oestermann (l.), Fraunhofer IZM, gave a guided tour of the 'Future Packaging' production line and also gave a forum presentation on 'Trust the Line - Competitiveness through Trust, Sustainable Tool and Supply Chain'

Exhibition offered a good overview and many suggestions

In line with its mission 'Everything's connected', ASYS exhibited a variety of flexible and scalable solutions for the production of the future. These included the autonomous depaneling system with offline programming ASYCAM Extended, the world's first fully automatic printer SERIO 6000 with newly developed paste pick-up, material logistics components for consumption-oriented replenishment that visually support operators with 'pick-by-light' and thus reduce errors, and the PULSE PRO software solution that allows you to maintain an overview no matter where you are.

In addition to test and inspection systems, ATEcare offers solutions for materials management in collaboration with materials storage specialist cts, as well as service and consulting services for all aspects of component and assembly transportation in intralogistics. With materials management 'by ATEcare', customers are supported from reading out the data, linking this information in the ERP, MES and other systems through to evaluating and interpreting the data. ATEcare also offers all the necessary hardware components required for efficient and reliable material management, from high-performance scanning tables for incoming goods to complex, fully automated storage systems and autonomous Omron-based transport systems.

The Smart In-Production Warehouse from cts, which is now also available in a small version, is an effective solution for the storage of assembly magazines that significantly reduces the space required for storage. The intelligent storage system has a modular design and can be adapted to the customer's individual requirements. At its core is an innovative, space-saving gripper system that ensures effective storage and retrieval. This concept not only offers the option of storing PCB magazines, but can also be modified to store KLT boxes for additional material such as items for final assembly or trays with semi-finished and finished products.

Balver Zinn is a manufacturer of solders and high-quality anodes made of zinc, tin, lead and their alloys as well as special tin and lead wires for the electronics industry and surface finishing. Cobar Europe is a member of the Balver Zinn Group and produces fluxes and solder pastes. Sustainability has not only been an issue for Balver Zinn since the introduction of e-CO2sol, it has always been a matter of course for the company. New is the reliable, low-melting alloy SnBi28, which is available as bar material for selective soldering systems and as the robust solder paste JEAN-151. The solder paste JEAN-151 SnBi28 is perfect for reflow soldering and for the vapor phase. Balver Zinn has also added a new series of cleaners to its range, such as the Spray Cleaner, which is a spray cleaner suitable for the ESD-safe removal of flux residues. The Equipment Cleaner is a foaming gel for manual cleaning of all types of soldering systems. Multi Cleaner is an aqueous, pH-neutral broad-spectrum cleaner for removing residues. It is suitable for removing flux residues, oils and greases.

Ricardo Schmidt with FlashFOX, a compact stand-alone production programmer for embedded in-system programming (ISP)For the first time since 2019, the Mechatronics & Automation cluster was once again represented with a joint stand. Together with four co-exhibitors from the network, the cluster presented itself in Hall 5. Schärer + Kunz, Fraunhofer EMFT and the Bavarian Chips Alliance of Bayern Innovativ exhibited at the joint stand. The joint project 'Additive4Industry - Printed electronics on 3D substrates' with the two project partners FAPS and Neotech AMT GmbH also presented itself.

Ricardo Schmidt with FlashFOX, a compact stand-alone production programmer for embedded in-system programming (ISP)For the first time since 2019, the Mechatronics & Automation cluster was once again represented with a joint stand. Together with four co-exhibitors from the network, the cluster presented itself in Hall 5. Schärer + Kunz, Fraunhofer EMFT and the Bavarian Chips Alliance of Bayern Innovativ exhibited at the joint stand. The joint project 'Additive4Industry - Printed electronics on 3D substrates' with the two project partners FAPS and Neotech AMT GmbH also presented itself.

With the new Vario Line 3D SPI system, Göpel electronic presented its innovative system solution for the 3D inspection of printed solder and sinter pastes. The new system is based on the proven hardware platform of the AOI product family Vario Line. At its heart is the high-speed 3D inspection module based on fringe projection, which guarantees maximum reliability and reproducibility thanks to its advanced technology. With the Vario Line 3D SPI, it is not only possible to inspect structure heights of just 30µm. In addition, a closed loop interface enables direct networking to paste printers or pick-and-place machines. It has a link to Pilot Connect, the standardized networking system for all inspection data from AOI, SPI and AXI for the central recording and management of machine and operating data.

The new SFX TIC022-HVPRG/SR was presented as a highlight. It is a special TAP Interface Card as an external test interface solution for all Scanflex II controllers SFX II CUBE and SFX II BLADE. It supplements the existing range of TAP Interface Cards (TIC) with a variant for flexible control of any serial test bus and debug protocols. In addition to JTAG, this also includes SWD, BDM, SBW, PIC1X and HS/CSI. Thanks to the reconfigurable architecture, the protocol scope can be extended at any time, even with modules already installed. On the software side, it is supported by the integrated JTAG/Boundary Scan platform System Cascon. With the help of VarioTAP technology, processors and µControllers can thus be transformed into very powerful design-embedded test and programming instruments without firmware. In addition, the new board can also be used to implement BS tests in accordance with IEEE1149.x, which enables combination tests with maximum static and dynamic fault coverage. The SFX TIC022-HVPRG/SR provides an additional programming voltage, which is necessary for HV programming of Microchip PIC devices, for example. This means that even devices that have already been programmed and blocked for standard access can be deleted and reprogrammed.

Spea's Multi-Core Multi-Function Board Tester 3030IL - a fully automatic in-circuit tester with four independent test cores for testing parallel PCBAs: It offers enormously high throughput without the operator having to assemble the PCB or perform the testSmartReppresented SMT process machines from assembly to depaneling as well as 3D inspection systems and material flow solutions. These included the new Hawkeye2000 X-ray component counter. It automatically records the barcodes and the position of the roll and automatically assigns the counting results in the MES/ERP system. The successor to the Hawkeye1000 scores points with the additional SmartCamera function, making the process even faster and more digital.

Spea's Multi-Core Multi-Function Board Tester 3030IL - a fully automatic in-circuit tester with four independent test cores for testing parallel PCBAs: It offers enormously high throughput without the operator having to assemble the PCB or perform the testSmartReppresented SMT process machines from assembly to depaneling as well as 3D inspection systems and material flow solutions. These included the new Hawkeye2000 X-ray component counter. It automatically records the barcodes and the position of the roll and automatically assigns the counting results in the MES/ERP system. The successor to the Hawkeye1000 scores points with the additional SmartCamera function, making the process even faster and more digital.

The automatic depaneling system was presented by SmartRep together with LPKF Laser & Electronics. SmartRep relies on laser separation and offers automation solutions in various stages. These range from semi-automatic tray solutions to cobot systems with test islands and fully automatic loading masters. Thanks to the latest technologies and the use of powerful laser sources, laser depaneling has become a real alternative for milling PCBs. The new 3000 series from LPKF uses the patented Tensor technology, which achieves the highest cutting speeds and 100% clean cutting edges.

The all-round iineo+ platform from Europlacer for placement offers high placement performance and is so flexible that it can be used in any high-mix, low-volume production environment. This is because 10 JEDEC trays, 264 feeder positions and electrical testing are already integrated in the standard version.

Viscom presented its latest 3D AOI system, the iS6059 PCB Inspection Plus. It offers nine views in first-class resolution and with 26% more pixels than the S3088 ultra gold AOI system. Variable illumination, larger tilted image fields at the same resolution, further increased data transfer rates combined with 25% faster imaging and extensive meshing options provide a solid foundation for unbeatable line-integrated performance. The iS6059 PCB Inspection Plus offers sophisticated inspection methods for fully automatic verification of whether the solder connection of even the smallest electronic component is still acceptable with short cycle times. Another 3D AOI system at the stand was the S3088 ultra chrome, which was shown in combination with state-of-the-art handling and smart verification, which offers new forms of assistance with artificial intelligence.

Carsten Salewski informed the press about Viscom's new products

Carsten Salewski informed the press about Viscom's new products

AI is currently a major topic at Viscom. Among other things, it is used when it comes to measuring voids in solder joints during an X-ray inspection and ruling out defects based on individual factors. Viscom systems such as the iX7059 PCB Inspection XL shown at SMTconnect detect these and other hidden defect types.

Sascha Frieling (Fuji Europe) shows us with noticeable enthusiasm the all-in-one placement machine Aimex R. The R stands for 'revolution'. The new Aimex offers a 20% shorter cycle time, real-time sensor technology and reduced energy consumption. The combination of real-time sensor technology and placement heads enables high throughput and high accuracy. The revolution can even be heard, as the pick and place machine is significantly quieter than its predecessor - and the elegant hood solution is impressive

Sascha Frieling (Fuji Europe) shows us with noticeable enthusiasm the all-in-one placement machine Aimex R. The R stands for 'revolution'. The new Aimex offers a 20% shorter cycle time, real-time sensor technology and reduced energy consumption. The combination of real-time sensor technology and placement heads enables high throughput and high accuracy. The revolution can even be heard, as the pick and place machine is significantly quieter than its predecessor - and the elegant hood solution is impressive

There was a lot more going on at the power electronics trade fair (PCIM Europe), which took place at the same time. No wonder: power electronics are in vogue. A panel discussion considered the reliability and quality requirements for SiC and gan power devices - and the revolutionary possibilities offered by the new materials. As a comparison, the question was posed as to which of Leonardo DaVinci's visions he would have been able to realize if materials other than cloth and wood had been available to him. Power electronics are now at a similar crossroads.

There was a lot more going on at the power electronics trade fair (PCIM Europe), which took place at the same time. No wonder: power electronics are in vogue. A panel discussion considered the reliability and quality requirements for SiC and gan power devices - and the revolutionary possibilities offered by the new materials. As a comparison, the question was posed as to which of Leonardo DaVinci's visions he would have been able to realize if materials other than cloth and wood had been available to him. Power electronics are now at a similar crossroads.

The next SMTconnect is expected to take place from June 11 - 13, 2024.

There was a lot more going on at the parallel trade fair for power electronics (PCIM Europe). No wonder: power electronics are in vogue. During a panel discussion, the reliability and quality requirements for SiC and Gan power devices were considered - and the revolutionary possibilities offered by the new materials. As a comparison, the question was posed as to which of Leonardo DaVinci's visions he would have been able to realize if he had had materials other than cloth and wood at his disposal. Power electronics is now at a similar crossroads.