A new technology from Dresden for the simultaneous measurement of water vapor and oxygen permeability rates is also suitable for use in electronic and optoelectronic components.

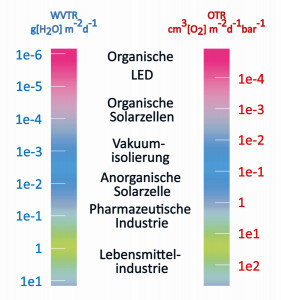

Fig. 1: Requirements of various fields of application for WVTR and OTRTheprecise determination of the water vapor and oxygen permeability (permeation) of encapsulation materials is of outstanding importance for a wide range of applications, including high-quality products such as food and pharmaceutical packaging, gas storage systems, e-readers, lithium-ion batteries and vacuum insulation panels. Especially for electronic and optoelectronic components, e.g. organic light-emitting diodes (OLEDs), the determination of gas permeability plays a decisive role.

Fig. 1: Requirements of various fields of application for WVTR and OTRTheprecise determination of the water vapor and oxygen permeability (permeation) of encapsulation materials is of outstanding importance for a wide range of applications, including high-quality products such as food and pharmaceutical packaging, gas storage systems, e-readers, lithium-ion batteries and vacuum insulation panels. Especially for electronic and optoelectronic components, e.g. organic light-emitting diodes (OLEDs), the determination of gas permeability plays a decisive role.

OLEDs are usually encapsulated in order to protect the organic layers from environmental influences and thus ensure greater efficiency and a longer service life. In particular, contact with moisture and oxygen leads to degradation, i.e. a change in the material properties. In order to maintain full functionality, OLEDs have extreme barrier requirements for the encapsulation material. These are a maximum water vapor transmission rate (WVTR) of 10-6gH2Om-2d-1 and a maximum oxygen transmission rate (OTR) of 10-4cm3m-2d-1bar-1 (Fig. 1).

Innovative measuring device

SEMPA SYSTEMS from Dresden has developed a state-of-the-art permeation measuring device based on a patent from the Fraunhofer Institute for Material and Beam Technology IWS. In collaboration with the Fraunhofer Institute for Material and Beam Technology (IWS), the engineers at the 'SEMPA Labs', a research and development laboratory within the company, have created 'HiBarSens 3.0', the first device that enables the WVTR and OTR of a sample to be determined in just one step. This means that the permeability for the most critical atmospheric gases can be measured simultaneously under the same experimental conditions. Low operating costs result from shorter measurement times, a small footprint and low handling costs.

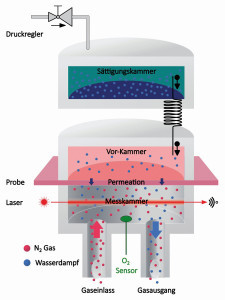

SEMPA SYSTEMS cites the combination of two measuring principles in a single measuring cell as an innovation of the new permeation measuring device: laser diode spectroscopy for measuring the water vapor concentration and fluorescence quenching for measuring the oxygen concentration (Fig. 2).

Fig. 2: Schematic representation of the 'HiBarSens 3.0' measuring principleAhorizontally arranged sample divides the module into two areas. Above the sample are the saturation chamber and the pre-chamber, which play a decisive role in maintaining a defined water vapor concentration during the entire measurement process. The measuring chamber is located directly below the sample. In the measuring chamber, the attenuation of the laser beam intensity is measured as a function of the water vapor concentration. As this laser diode spectroscopy uses the characteristic absorption lines of a gas at certain wavelengths, interference from irrelevant molecules is excluded.

Fig. 2: Schematic representation of the 'HiBarSens 3.0' measuring principleAhorizontally arranged sample divides the module into two areas. Above the sample are the saturation chamber and the pre-chamber, which play a decisive role in maintaining a defined water vapor concentration during the entire measurement process. The measuring chamber is located directly below the sample. In the measuring chamber, the attenuation of the laser beam intensity is measured as a function of the water vapor concentration. As this laser diode spectroscopy uses the characteristic absorption lines of a gas at certain wavelengths, interference from irrelevant molecules is excluded.

At the same time, a specially coated pad is irradiated with green LED light for fluorescence quenching so that it emits fluorescent light. Each oxygen molecule in the immediate vicinity partially extinguishes the fluorescent light. The decrease in this luminescence signal is then measured as a function of the oxygen partial pressure.

The nitrogen supplied to the measuring chamber regulates the concentration of the water vapor and oxygen molecules that have penetrated the sample to be examined (permeate). Automatically opened and closed valves allow a discontinuous flow of nitrogen to regulate the permeate concentrations. As a result, even small quantities of permeate can be enriched to such an extent that they can be reliably measured, provided that all equilibrium conditions are met.

The methods described enable reliable determination of the WVTR in a wide dynamic range between 10 and 10-6gH2Om-2d-1, which is currently the lowest limit of detection (LOD) that can be achieved with a commercial product. In the OTR range, the detection limits of the HiBarSens 3.0 are between

103 and 10-3 cm3 m-2 d-1 bar-1.

Active sealing technology

In order not to falsify the measurement results, the inserted samples must be hermetically sealed. The sealing technology used for this must not damage the samples mechanically. This is a challenging task, as the typical sealing solutions, i.e. metallic seals and polymer-based sealing materials, must not be used. While metallic seals can destroy the sample due to their hardness, polymer seals are themselves susceptible to permeation.

'HiBarSens 3.0' uses an active sealing technology ('ActiveSeal') without sealing materials. Two special flushing channels outside the measuring range are continuously supplied with dry nitrogen. As a result, each channel reduces the diffused ambient humidity - by several orders of magnitude. This ensures a perfectly sealed environment and supports precise measurements and analyses.

Significant reduction in measurement time

Currently, measuring the Water Vapor Transmission Rate (WVTR) is a time-consuming process, especially for nearly impermeable samples. Their measurement time could theoretically be infinite. SEMPA's permeation measuring device meets this challenge with two important functions. Firstly, the measuring temperature can be increased up to 85 °C, resulting in a higher permeability rate.

Secondly, 'PreConCell' technology can be used in parallel with the measurement. PreConCell' has independent chambers in which the samples are preconditioned before measurement. The technology generates the required moisture gradient in the samples and ensures a perfectly prepared sample by adjusting the relative humidity from dry to 95 % RH (relative humidity). Depending on the sample properties, this allows measurements to be taken up to ten times faster. Operation at higher temperatures even enables measurements up to 300 times faster.

User-friendly graphical interface

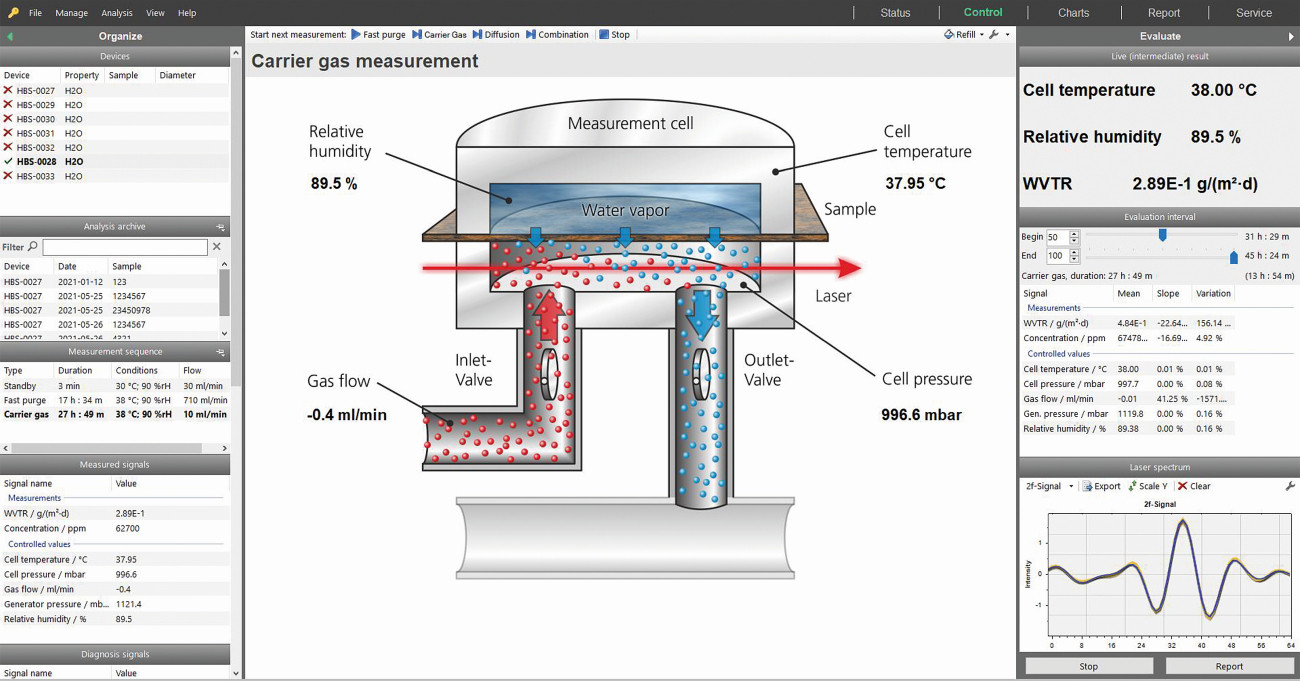

'Permalyzer Pro' is a user-friendly graphical user interface (GUI) that has been developed to control and interact with the permeation meter (Fig. 3). It is the central hub through which users can manage and control the functions of several 'HiBarSens 3.0' devices simultaneously. 'Permalyzer Pro' simplifies the configuration, starting and monitoring of measurements and enables smooth operation. It is also possible to retrieve measurement data, create diagrams and export measurement reports.

Fig. 3: Permalyzer Pro - the GUI of the permeation meter; images: SEMPA SYSTEMS

Fig. 3: Permalyzer Pro - the GUI of the permeation meter; images: SEMPA SYSTEMS

Johannes Grübler completed his degree in 'Physical Engineering' with a specialization in photonics at the Mittweida University of Applied Sciences. In his diploma thesis, he researched the permeation behavior of ultra-barriers. He has been a member of the SEMPA SYSTEMS development department since 2009 and has headed it since 2020.

Johannes Grübler completed his degree in 'Physical Engineering' with a specialization in photonics at the Mittweida University of Applied Sciences. In his diploma thesis, he researched the permeation behavior of ultra-barriers. He has been a member of the SEMPA SYSTEMS development department since 2009 and has headed it since 2020.Contact: