A study shows that injection molding and laser direct structuring based on a modified polyether ether ketone (PEEK) can replace previous silicon substrates. The material is cheaper and makes it possible to reduce the necessary work steps from 7 to 3.

In a study, the Institute of Micro Production Technology at Leibnitz University Hannover (IMPT) examined alternative production methods for sensor applications and identified great market opportunities for the combination of injection molding and laser direct structuring based on PEEK for the production of sensors and microsystems. The market for sensor applications is large: microsystems are used in large quantities in the IT and telecommunications sector, the automotive and aerospace industries and in plant and mechanical engineering.

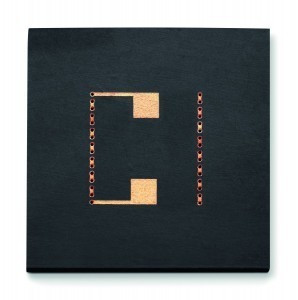

Until now, the technological basis for such electronic components has been wafers - thin slices of silicon to which thin films are applied. The production and further processing of silicon wafers is very complex and expensive. To produce a temperature and magnetic field sensor as a functional demonstrator, injection molding was combined with laser direct structuring (LDS) - based on the material Tecacomp PEEK LDS black 1047045, a high-performance compound from Ensinger.

Three instead of seven production steps

The production of an encapsulated sensor, which can be easily integrated into PCB assembly processes, involves three production steps using the LDS process:

- In the first step, the substrates are made from laser-activatable plastic using an injection molding process. Predefined sensor structures and vertical electrically conductive connections (VIA) for vias are taken into account.

- The next step is the laser drilling of recesses and the activation of the LDS-compatible polymer by an electroless, selective deposition of metals.

- An unstructured sensor layer is then applied using cathode sputtering. The required structures are then exposed using the CMP process (chemical-mechanical polishing).

This process chain reduces the complexity of production and packaging. In contrast to the use of classic silicon wafers, no clean room environment is required and the complex photolithographic structuring is completely eliminated.

Thermoplastics for cost-effective sensor production

The LDS process places particularly high demands on the polymer in the production of microsystems. According to Ensinger, it is currently the only plastics specialist that can offer a PEEK certified by LPKF Laser & Electronics AG for the LDS process. Tecacomp PEEK LDS black 1047045 is optimized with mineral fillers. The material is extremely temperature-resistant (permanently up to 260 °C), has very good weld line strength, good adhesive strength and shows high chemical resistance to solvents. It also has a very low coefficient of linear thermal expansion, which is closer to that of metals than that of many other plastics.

The use of laser-activatable high-performance polymers instead of silicon as a substrate for wafer production can not only reduce the number of process steps but also bring significant cost benefits in production. Stefan Bur, Application Segment Manager MID/LDS at Ensinger, sees great potential in this innovative application: "In the electronics industry, the polymer PEEK in particular is gaining in importance due to its special properties. The IMPT study has shown that it can be used as a wafer material. In initial applications, the sensor demonstrated around 75% of the performance of a conventional silicon-based sensor. The potential savings in manufacturing costs amounted to 90 %." In the future, Bur estimates that medium-sized companies will also be able to produce cost-effective wafers for microsystems technology using the LDS process.

The compounds may be of interest for sensors in electrical engineering, mechanical engineering and medical technology. Possible fields of application include position sensors (AMR and GMR sensors), eddy current sensors, temperature sensors for measurements in laboratories or industrial processes (thin-film PT sensors) or DC/DC converters.

A variety of manufacturing processes can be used to process thermoplastic engineering and high-performance polymers, including extrusion, machining, injection molding, compression molding, sintering and pressing.