Efficiency is extremely important in all manufacturing processes. This is why connection technology for the wiring of PCBs has been constantly evolving. Push-in and lever push-in connections are already tool-free and easy to use. The new Push-X technology based on the mousetrap principle builds on this.

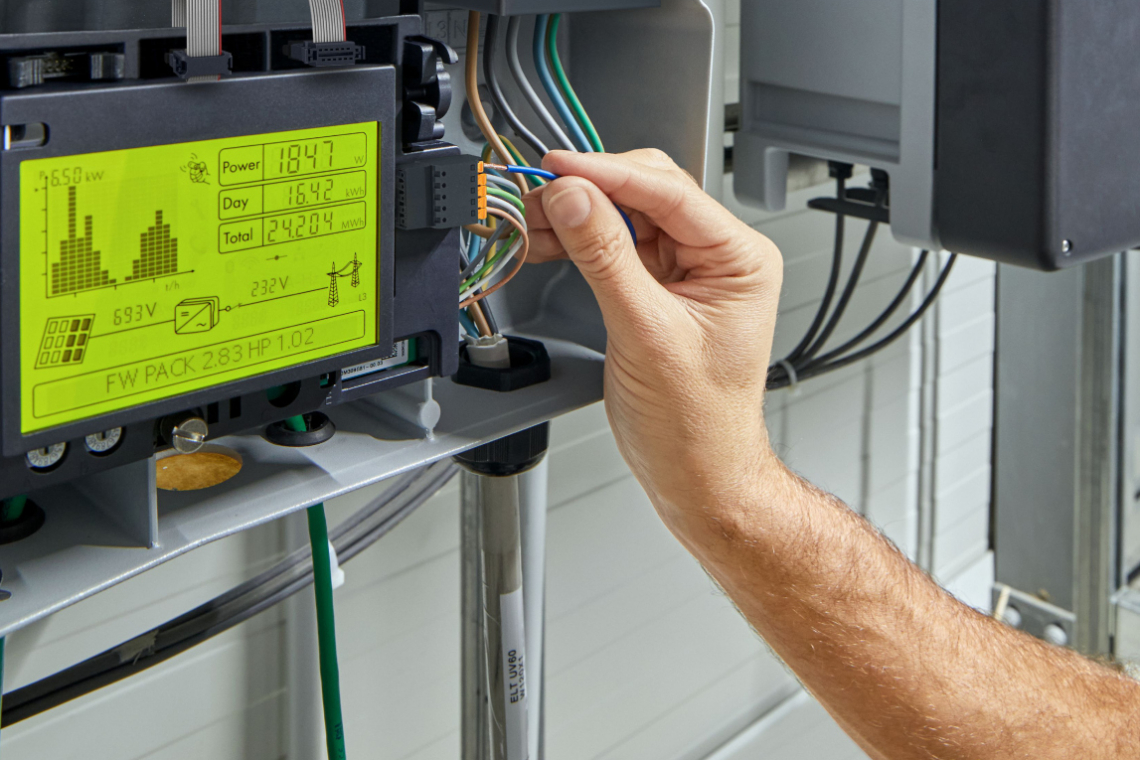

Electrification has become an integral part of all areas of life. The necessary components with their integrated circuit boards must be connected simply and securely. User-friendly conductor connection technology helps with wiring. This includes the push-in spring connection, where rigid or flexible conductors with ferrules are simply pushed into the connection compartment without tools. With flexible conductor ends, however, it is necessary to open the clamping spring. This process is not easy to carry out with two hands. This is how the idea for PhoenixContact's Push-X technology was born.

Connecting flexible conductors easily and without tools

The XPC 1.5 connectors are the first PCB components with the Push-X connection. Flexible class 5 conductors from 0.5 to 1.5 mm² can be plugged in directly without a ferrule. This is particularly helpful when wiring in the field if the right crimping tool for the wire end ferrule is not to hand. Of course, it is still possible to connect rigid and flexible conductors with ferrules. When inserting the conductors for the first time, it is surprising how little force is required to make the connection.

What is the difference between Push-X and Push-in?

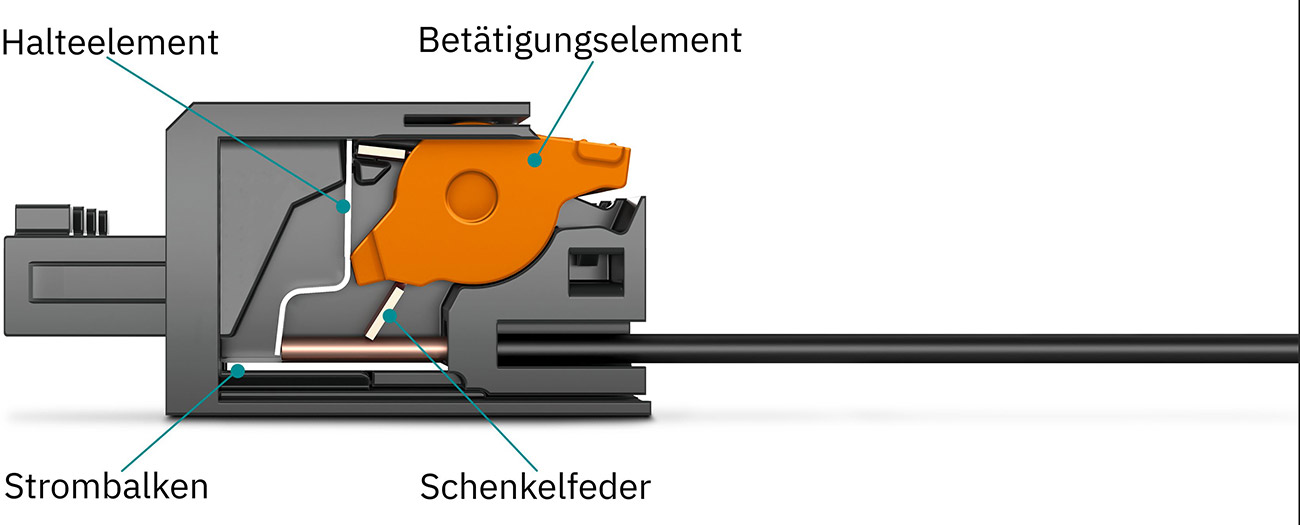

The basic structure is very similar. Both connection types have socket contacts, leg springs for conductor clamping and actuating elements. However, the delivery state of the leg spring is closed for push-in products. This means that with Push-in, the conductor must first push the spring upwards, which causes higher insertion forces. With Push-X, the clamping chamber is open on delivery. The additional retaining element on Push-X ensures that the open spring is held in place.(Fig. 1)

Fig. 1: The design enables force-saving and tool-free conductor connection

Fig. 1: The design enables force-saving and tool-free conductor connection

Force and tool-free direct plug-in technology

The Push-X connection is based on the mousetrap principle. The leg spring is open and the conductor is inserted. This hits the sensitive release element, which then releases the pre-tensioned leg spring. The spring snaps shut with an acoustic signal and presses the conductor firmly against the current bar of the connector for a long-term stable connection. At the same time, the orange actuating element swivels upwards and signals that the clamping area is closed(Fig. 2). A video animation for the Push-X connection can be viewed on the website www.phoenixcontact.com using the web code #3261. In order to prevent the mousetrap from being triggered unintentionally by vibrations, the right compromise had to be found in the design. On the one hand, the triggering should be very sensitive to enable the connection of very small conductor cross-sections and to keep the operating forces low. On the other hand, there are the ambient and transportation conditions, which should not cause any unwanted triggering of the leg spring. The XPC 1.5 connectors have undergone extensive climate, vibration and drop tests to ensure that they arrive at the user with the terminal chambers open and meet the safety requirements of IEC 61984. VDE and UL-1059 approvals certify the quality level of this product.

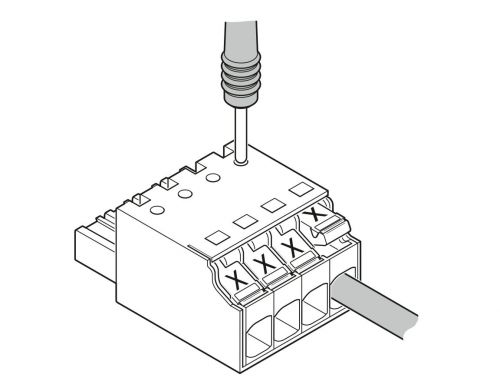

Fig. 3: In addition to Push-X, the PCB connectors have other practical advantages. For example, the XPC 1.5 connector is equipped with test openings on the top that enable electrical function testing in the application. Contact can be made directly on the current bar of the respective poles using 1 mm test probes.

Fig. 3: In addition to Push-X, the PCB connectors have other practical advantages. For example, the XPC 1.5 connector is equipped with test openings on the top that enable electrical function testing in the application. Contact can be made directly on the current bar of the respective poles using 1 mm test probes.

Frequent conductor connection and compatibility

DIN EN 60999-1 requires the largest conductor cross-section to be connected and disconnected five times and UL 1059 ten times. Even after 25 connection processes, no deterioration was detected in the laboratory. The clamping chamber is opened by pressing down the orange actuating element until it engages in the lower position. This automatically prepares the leg spring for the next connection process.

The XPC 1.5 series is compatible with PhoenixContact's existing 3.5 mm pitch product range. The XPC can be combined with existing horizontal and vertical base strips. Further products with Push-X technology for larger conductor cross-sections will follow this year with the XPC 2.5 series.

Conclusion

Push-X technology brings convenience and speed to installation and low conductor connection forces for the user. The connection is confirmed visually and acoustically. Conductors can be plugged in directly without ferrules. This saves time and money. Processes are so simple that they can be easily automated.