A silicon strain gauge (Si-DMS) is being used for the first time in Turck duotec's force sensor platform. The miniaturized sensor for weight and force measurement is predestined for harsh operating conditions.

The Si strain gage differs fundamentally from a foil strain gage: Due to its small size, the force is determined on a point-specific basis. The sensor uses piezoresistivity, which results in its high sensitivity. These properties, in combination with the manufacturer's highly automated and high-quality production, predestine the new platform for new applications, for example in endoscopy or non-invasive pressure measurement.

Long-term stability and precision in harsh environments

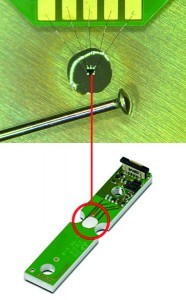

The sensor chip of the new force sensor platform with a size of 0.5 mm x 0.5 mm in comparison with a pinThesilicon strain gauge for detecting deformations is either glassed or glued onto a spring body. The assembly and connection techniques used (AVT) offer particularly rigid and media-resistant connections between the spring body and the Si strain gauge over high temperature ranges and even in the presence of moisture.

The sensor chip of the new force sensor platform with a size of 0.5 mm x 0.5 mm in comparison with a pinThesilicon strain gauge for detecting deformations is either glassed or glued onto a spring body. The assembly and connection techniques used (AVT) offer particularly rigid and media-resistant connections between the spring body and the Si strain gauge over high temperature ranges and even in the presence of moisture.

The sensor can also be shielded from the environment using protection methods such as direct overmolding. The sensor chip measures just 0.5 mm x 0.5 mm. The tiny device is characterized by its high sensitivity and particularly good signal quality. It is media-resistant, stable over the long term and can also be produced automatically and cost-effectively in large series.

Digital signal processing and miniaturized design

The platform includes signal processing and digitization, which includes calibration and temperature compensation. Different materials can be used as spring bodies, as even minimal deformations of the spring body can be determined. The mechanical integration is always designed and simulated on a customer-specific basis.

The optimized power consumption and miniaturization make the platform suitable for the implementation of autonomous IoT sensors. It can also be used in the harsh environments of mobile machines and in power generation systems. The monitoring of filling quantities and the simultaneous detection of collisions are also feasible. Turck duotec also offers a platform solution for wireless data transmission.

Leading in the EMS world

The Turck duotec Group is one of the leading global solution providers for innovative electronics, connectivity and the various forms in the EMS market (EMS+, E²MS/Electronics Engineering and Manufacturing Services, ODM/Original Design Manufacturing) as well as for the IoT. Locations are in Halver, Grünhain-Beierfeld, Delémont (CH) and Arteaga (Mexico). The participating companies also include ml&s manufacturing logistics & services GmbH & Co KG Greifswald. The companies are certified to ISO 9001, EN ISO 13485, IATF16949 and ISO/IEC 17025, among others, and develop specific electronic solutions for automotive, energy, building automation, industry, medical technology, mobility, telecommunications and IT.