The semiconductor crisis is the next low for the industry. The automotive industry is particularly hard hit. New cars are fitted with analog speedometers instead of digital ones, production lines come to a standstill and employees have to work reduced hours despite full order books [1]. One reason for the crisis: supply bottlenecks for raw materials and geopolitical tensions [2].

Currently, the relevant components are only available from manufacturers with very long delivery times, if at all. The industry's response to the long delivery times for semiconductors is to switch to so-called procurement service providers. One problem with this practice is that often little is known about the sources from which these parts originate. This opens up new problems, as the so-called "free market" contains a large number of counterfeit, manipulated and used parts that are declared as new [5].

Systematically detect component manipulation

Reliable products cannot be manufactured with components whose properties do not correspond to the data sheet and which fail after a short period of use due to their low quality or "early life". If just one component on a circuit board fails, the entire assembly is usually without function [3], which is particularly precarious for safety or life-critical systems such as driver assistance systems and brake control systems.

But what are the alternatives? Stop production due to components of dubious origin? Or is there a way to detect counterfeit electrical components in advance?

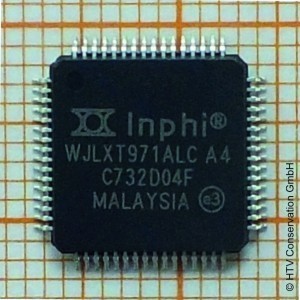

The times when counterfeits could still be identified quite simply by poorly copied logos or incorrect labeling, for example, are over. With margins of over 300% [3], the effort required by counterfeiters to disguise counterfeits as effectively as possible is extremely profitable [4]. In many cases, counterfeit components can hardly be distinguished from the originals, which is why a suitable strategy is required to ensure quality and determine authenticity.

Fig. 1: Even components worth just one euro are counterfeited. In this case, an operational amplifier from the manufacturer Texas Instruments was ordered (left), but a counterfeit, unlabeled chip was delivered (right). Although this might pass the electrical tests, it would not deliver the same reliability as a high-quality chip from TI

Counterfeit screening

Appropriate strategies for ensuring the quality and determining the authenticity of components procured on the open market are therefore essential for maintaining the quality and integrity of our own products. Ensuring component quality and availability in advance is one of the competencies of the HTV Group, which specializes in component programming and processing in addition to testing, analysis, long-term preservation and long-term storage.

The HTV Institute for Material Analysis offers numerous options for evaluating the originality and quality of supplied parts and detecting any component manipulation: First of all, correct functionality and compliance with the data sheet parameters must be ensured. At HTV, this is done using complex digital and mixed-signal large-scale test systems or test applications created specifically for the desired tests. This allows an initial statement to be made regarding the authenticity of the component without further analysis.

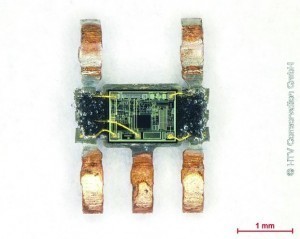

As shown in Figure 1, it is often necessary to carry out subsequent detailed examinations of both the external (e.g. incoming goods inspection, light microscopy, wipe test) and internal structure (e.g. acoustic microscopy, X-ray, chemical component opening). For example, a wipe test is used to treat the component surface with special chemicals so that it can be determined whether the component has been subsequently re-labeled and thus re-declared or manipulated. But here too, counterfeiters are constantly learning. The techniques used can often no longer be detected using standard procedures such as a wipe test. Such forgeries or manipulations can be detected with a chemical component opening, but also with the help of acoustic microscopy (SAM).

In view of the current situation, it is absolutely advisable to check the authenticity of components that come from procurement service providers. This is the only way to ensure the reliability and function of the final product and keep the number of complaints low. For these tasks, the HTV Institute for Material Analysis offers numerous comprehensive analysis methods as a service, with which the quality of the supplied components can be ensured.

Fig. 2: New counterfeiting techniques are becoming increasingly difficult to detect. They sand off the old lettering and then use the sanded material to reapply it to the component surface with epoxy resin. This preserves the original appearance of the housing. The parts are then re-labeled. The problem: a wipe test is inconspicuous in this case (left). An examination of such components with a Scanning Acoustic Microscope (SAM), on the other hand, reveals the original writing and thus the truth

Ageing can be prevented

If a company is lucky enough to be able to buy authentic parts, the question of purchasing volume arises. In times like these, which are difficult to plan, just-in-time production without warehousing is no longer possible. But where should the components be stored? And above all, how can these parts be preserved for years without losing quality and functionality? HTV can also help with this problem. With the specially developed TAB long-term preservation and storage process, which is unique in the world, components can be preserved in high-security buildings for up to 50 years. In contrast to conventional storage methods (e.g. in nitrogen drypacks), the specific ageing processes, such as diffusion, can be drastically reduced and in some cases even prevented. The availability of the stored electronic components can also be monitored and predicted using a wide range of analysis methods. In this way, the supply of important components for production can be ensured for decades to come.

References and notes:

[1] https://www.auto-motor-und-sport.de/verkehr/autohersteller-prozessoren-halbleiter-schaltkreise-produktionsstopp-pc-homeoffice/

[2] https://www.springerprofessional.de/halbleiter/halbleitertechnik/das-muessen-sie-zur-halbleiter-krise-wissen/19356172

[3] https://www.elektronikpraxis.vogel.de/vorsicht-gefaelschte-halbleiter-das-schmutzige-geschaeft-mit-plagiaten-a-727271/

[4] https://www.industr.com/de/woran-sie-gefaelschte-halbleiter-erkennen-2533740

[5] https://www.heise.de/news/Chipmangel-Warnung-vor-gefaelschten-Halbleiter-Bauelementen-6069089.html