IPC wants to incorporate more environmental aspects into design in future

For years, the US industry association IPC has kept environmental issues in the design and production of printed circuit boards, assemblies and devices on the back burner. Now it seems to be attaching significantly more importance to it. The aim is to realize an effective circular economy.

With the development of IPC-1402, the working draft of which was released for broad discussion in June 2022, the association is aiming for the first time to focus on environmental issues in the use of cleaning chemicals in addition to lead-free solders in a new standard. The guideline entitled 'IPC-1402: Standard for Green Cleaners Used in Electronics Manufacturing' is to be completed by the end of the year as a result of international work.

Daring more ecodesign

In August of this year, the IPC announced that it also intends to focus more on the growing role of ecodesign in the design of electronics, namely in the revision of IPC-2231 'Design for Excellence' (DFX) as part of the current B revision. This IPC guideline document, first published in 2019, provides a framework for establishing a design review process for the layout of printed circuit board assemblies. Important manufacturing attributes of printed circuit boards are checked: Design for Manufacturing of the boards and the assemblies, design for test, cost aspects, reliability, environment and reusability. The management of the IPC explained in the press release that it is aware that electronics manufacturers will be confronted with increasing environmental requirements from regulatory authorities worldwide in the near future and will have to respond to them.

IFA 2022 as an environmental driver and mobilizer?

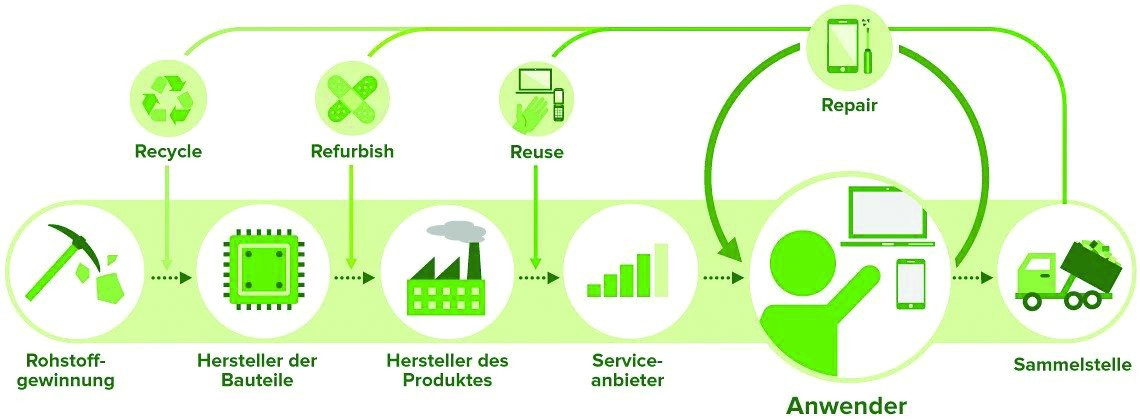

The IPC's statement comes at a time when the world's largest trade fair of its kind, IFA 2022 in Berlin in September, is also conspicuously focusing on sustainable electronics and household technology with a lower carbon footprint. From September 2 to 6, research institutes, start-ups, associations and experts from industry and science will be presenting innovative solutions as part of the IFA NEXT innovation platform in Hall 20 of the Berlin exhibition grounds in order to drive the development towards greater sustainability in the electronics industry. For example, resource-saving and CO2-neutral production, reparability and recycling will play a key role (Fig. 1). It will also be interesting to see what the major international electronics companies such as Philips, Sony, Samsung Electronics etc. have to say on this topic during the IFA, for example on a 'circular economy'. The PLUS will report on whether and to what extent a new quality of optimism can be observed.

Fig. 1: A circular economy is still a long way from being implemented in the PCB industry

Fig. 1: A circular economy is still a long way from being implemented in the PCB industry

Environmental issues in IPC-2231A and auxiliary documents sparse so far

After the first publication of IPC-2231 in April 2019, the revised IPC-2231A followed in August 2021. The 1-14 DFX Committee of the IPC is currently actively reviewing IPC-2231A with a view to revising it and publishing it as a B version within the next two years. This is a very long time, given the urgency of a major change of direction in the electronics industry towards an environmentally sound circular economy.

According to both the IPC and the standardization committee, the revision of the DFX guideline document is a top priority. The team anticipates that it may be able to expand IPC ecodesign activities to enable the creation of a new ecodesign guideline for electronics that takes a holistic view of the electronics creation process, incorporating circularity concepts and touching on every technological step from raw materials to recycling and reuse.

The magnitude of the task facing the IPC becomes clear when you take a closer look at the current IPC-2231A [1]. The document has 48 pages and is divided into 14 chapters (the rounded page numbers are in brackets):

- Overview (1)

- Applied documents (2)

- Terms and definitions (1)

- Overview of Design for Excellence Practices (DFX) (3)

- Design process for printed circuit board assembly (5)

- Board manufacturing process (4)

- Assembly process (7)

- Testability (DFT) (4)

- Cost (2)

- Design for reliability (3)

- Environmental design (1)

- Design for reusability (1)

- Checklist comparisons (17)

- Abbreviations (1)

Fig. 2: The transition to a circular economy is intended to reduce the pressure on natural resources Only two pages of the document deal with the two topics of 'eco-design' and 'design for reuse'. However, a fundamentally new Ecodesign Directive that includes the circular aspect would have to deal fundamentally with the 4R (Reduce, Repair, Reuse, Recycle) problem areas. This shows that even a revised edition of IPC-2231B, which, as announced, is not due to appear for another two years, can hardly meet the requirements of an ecodesign directive and is also rather late in coming. Conclusion: The IPC will not be able to avoid developing a completely new and ambitious guideline for ecodesign. Nevertheless, it must be said that the work of the industry association would be in line with the new Circular Economy Action Plan (CEAP) adopted by the European Commission in March 2020. It is one of the most important building blocks of the European Green Deal(Fig. 2) and an essential prerequisite for achieving the EU's climate target by 2050 [2].

Fig. 2: The transition to a circular economy is intended to reduce the pressure on natural resources Only two pages of the document deal with the two topics of 'eco-design' and 'design for reuse'. However, a fundamentally new Ecodesign Directive that includes the circular aspect would have to deal fundamentally with the 4R (Reduce, Repair, Reuse, Recycle) problem areas. This shows that even a revised edition of IPC-2231B, which, as announced, is not due to appear for another two years, can hardly meet the requirements of an ecodesign directive and is also rather late in coming. Conclusion: The IPC will not be able to avoid developing a completely new and ambitious guideline for ecodesign. Nevertheless, it must be said that the work of the industry association would be in line with the new Circular Economy Action Plan (CEAP) adopted by the European Commission in March 2020. It is one of the most important building blocks of the European Green Deal(Fig. 2) and an essential prerequisite for achieving the EU's climate target by 2050 [2].

The fact that environmentally friendly design has not played a significant role for the IPC in recent years is also reflected in the 'IPC Checklist for Producing Rigid Printed Board Assemblies', which can be viewed or downloaded at [3]. Lars Wallin helped develop this comprehensive and detailed 28-page methodical checklist in 2016 as a team member of the IPC to help designers and manufacturers of printed circuit boards use IPC standards in the development and production process. One reason for this: There are many parameters to consider in the entire creation chain of a finished rigid PCB that relate to the individual production steps and are contained in different IPC standards. The DFX standard IPC-2231 is logically not yet mentioned in the 2016 checklists for the entire process, from the start of the project to the CAD process, the board order process, production, cleaning and conformal coating. Environmental considerations therefore do not yet play an explicit role here. The same applies to the IPC Standards Tree contained therein. In contrast, the separate 'IPC Standards Tree 2021' already includes IPC-2231 with its low environmental content.

Nevertheless, this checklist with its symbolic illustrations of the production processes of boards and assemblies and the detailed IPC standards is a very useful and illustrative tool for all those who are concerned with the use of the complex set of IPC guidelines or want to gain further qualifications.

Broad support from research and industry needed

In its August communication, the IPC made it clear that it is well aware of the magnitude of the task of developing a detailed ecodesign standard from a circular economy perspective. "We believe this is an excellent opportunity to take a real step toward ecodesign for circular electronics - but it all starts with the IPC-2231 DFX guidelines document," said Patrick Crawford, IPC Manager of Design Standards and Related Industry Programs, who is also the IPC Staff Liaison to the 1-14 DFX Committee. "While the IPC is firmly committed to helping electronics manufacturing companies become more environmentally friendly themselves, organizations like the IPC rely on industry and institutions to provide significant support by participating heavily in standards committees and providing input into the development of the necessary standards. Only together can the necessary and meaningful changes be brought about."

Experts in green PCB design techniques, materials, manufacturing technologies, procurement, policy and regulation development are invited to help develop the next green design standard. The IPC invites anyone with expertise or passion for designing a green future that benefits both industry and the environment and who would like to contribute to the establishment of a best practice design methodology to contact Patrick Crawford [4].

References

[1] www.ipc.org/TOC/IPC-2231A_TOC.pdf

[2]https://environment.ec.europa.eu/strategy/circular-economy-action-plan_en

[3] www.ipc.org/ipc-standards-related-resources

[4] Email: