The integration of electrical and electronic systems is complex - as the powertrain of vehicles shows: it is not just about electrical drive technology and the power electronics involved, but also about the associated software. Development requires holistic approaches.

Cross-industry trends are challenging traditional methods for developing products in vehicle and mechanical engineering. The electrification of vehicles is rapidly gaining in importance in the automotive industry, the aerospace industry and in heavy mechanical engineering due to consistent further developments in the electric drivetrain and the looming restrictions imposed by new environmental regulations. At the same time, products in all sectors are becoming more intelligent and networked through the integration of highly developed electronic components and embedded software.

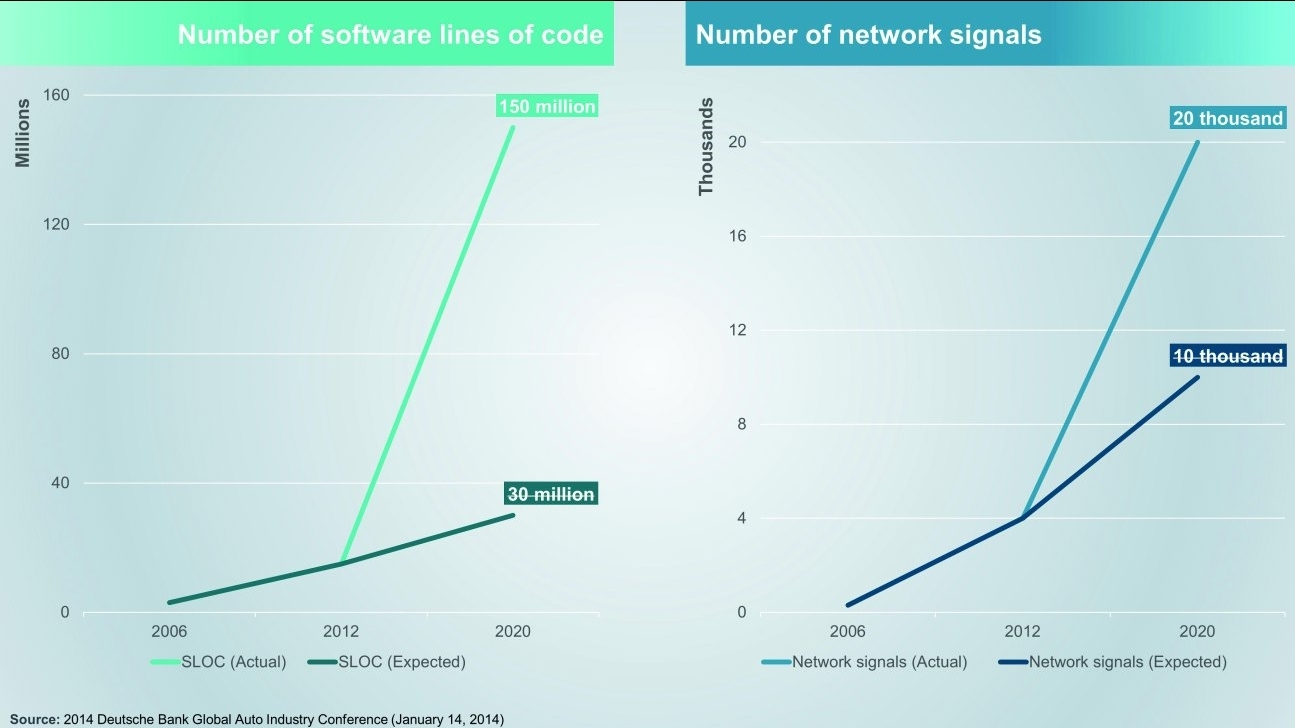

These trends are leading to a significant increase in the importance and complexity of electrical/electronic (E/E) systems in a wide range of products, from passenger cars and airplanes to marine vessels and advanced industrial machinery. In fact, the rapid growth in complexity has exceeded predictions. A 2014 study by Deutsche Bank predicted that by 2020, a vehicle would contain an average of 30 million lines of software code (SLOC) and 10,000 network signals. In reality, however, today's vehicles often contain 150 million SLOCs and more than 20,000 network signals (cover image).

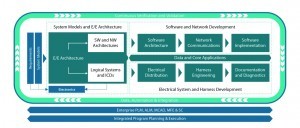

The increasing complexity of an E/E system is not just a result of more electrics, electronics or software in the respective products. Each included subsystem must integrate a diverse combination of different disciplines to enable the desired product functionality. Engineers must keep thousands of components and functions under control across disciplines to coordinate the development, simulation and validation of electrical systems, electronic control units (ECUs), software applications and more.  Fig. 2: Vehicle and machine manufacturers must adopt a method that dissolves the boundaries between development disciplines and supports holistic data continuity

Fig. 2: Vehicle and machine manufacturers must adopt a method that dissolves the boundaries between development disciplines and supports holistic data continuity

The traditional separation of individual disciplines - referred to as 'silos' - often leads to inconsistent implementation of requirements in the design of subordinate systems, a lack of communication between the individual disciplines and insufficient traceability of design steps. The resulting misinterpretations or inconsistencies only become apparent when various subordinate systems are integrated into a common, higher-level system. The costs for solving such problems at this late stage of development are then considerably higher. However, companies in all sectors are subject to increasing competition and the expectation of launching products on the market faster and faster. This requires development cycles to be shortened. Companies are striving to use new technologies and innovative designs and must implement these faster than ever before due to market conditions.

End-to-end process chain: development at a higher level

Today and in the future, there is a need to support cross-discipline integration and break down the boundaries between separate development disciplines ('silos') to ensure data continuity throughout the design process, manufacturing and maintenance of E/E systems(Fig. 2). With this approach, companies drive the design of electrics, electronics, networks and embedded software architecture from the E/E system architecture. Downstream support for harness manufacturing and vehicle maintenance completes the holistic development environment for E/E systems.

This comprehensive development environment offers a number of benefits to companies looking to develop next-generation products. The most important of these are accelerating time to market, reducing program risk, increasing product quality, optimizing collaboration and a stronger focus on innovation.

Faster time to market

The integrations supported by a comprehensive E/E development environment dramatically simplify the exchange of critical data between development teams and disciplines. With direct links to mechanical CAD, PLM, ALM, simulation tools and an integrated E/E system design and manufacturing portfolio, engineers can exchange information directly through their respective tools, providing the added benefit of traceability of changes and duplication of design work. This reduces downtime during data transfer and eliminates errors that can occur during manual data entry.

Powerful automation technology can further accelerate the development of E/E architectures, wiring harnesses (EDS) or networks, as well as the creation of reports and documentation for manufacturing or maintenance. Rule-based automation capabilities can assign functions to existing components within an E/E architecture, synthesize wiring, and generate reports and documentation based on rules and constraints defined by engineers. The result is fast, repeatable and accurate design creation, allowing engineers to focus on finding the optimal solution instead of labor-intensive manual tasks.

Reduced program risk and improved product quality

In today's competitive markets, there is a constant need for innovation, which increases the risk for new development programs. Increasing design complexity, new regulations and new competitors in the marketplace only add to the urgency for companies to assess program risk.

By moving to an integrated, digitized approach, manufacturers will be able to achieve a much better balance between innovation and risk at all times, using the latest product and production process knowledge in the form of widely available digital twins. Robust traceability ensures the development of products in accordance with internal and regulatory requirements and restrictions. Above all, it enables a verifiable development process to detect errors or mistakes at an early stage.

Advanced simulation and validation capabilities not only help to reduce the risk associated with developing complex products, but can also help to improve product quality prior to market launch. The ability to shift validation earlier in the development process enables engineers to verify and validate the functionality and performance of the product and its sub-systems earlier in the development process. Real-time captured metrics also enable immediate feedback on design decisions, allowing engineers to quickly perform 'what-if' analysis and iteration to achieve optimal implementation.

Optimized collaboration

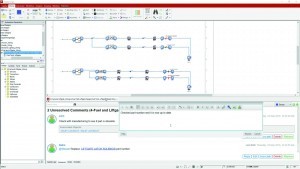

Fig. 3: Notes and comments in the design ensure structured and consistent communication between engineers. Here, the response to a comment describes the successful execution of a required changeTheincreasing complexity of vehicles and systems also requires clearly structured and regular communication between engineers to enable efficient and accurate designs. Today's common communication methods (email, phone calls, etc.) are disorganized, error-prone and unsuitable for subsequent traceability. Requests for reviews, updates and other communications are easily lost in the mass of numerous other emails and meetings, delaying the progress of design work.

Fig. 3: Notes and comments in the design ensure structured and consistent communication between engineers. Here, the response to a comment describes the successful execution of a required changeTheincreasing complexity of vehicles and systems also requires clearly structured and regular communication between engineers to enable efficient and accurate designs. Today's common communication methods (email, phone calls, etc.) are disorganized, error-prone and unsuitable for subsequent traceability. Requests for reviews, updates and other communications are easily lost in the mass of numerous other emails and meetings, delaying the progress of design work.

Modern E/E development systems provide solutions that help to optimize communication between the engineers involved. This allows them to contribute their notes and comments during system development. Such notes help engineers to coordinate designs with each other. They can be assigned to specific components, which makes it easier to find information(Fig. 3). The response to a comment creates a common thread for further communication. Integrated checklist functions help engineers to keep track of which tasks have already been completed and which are still unfinished. Finally, the modern development software for E/E systems supports configurable e-mail notifications for design updates and a reply function to keep the user up to date with development activities.

Integrated E/E solution solves tomorrow's challenges

Common trends in the automotive, aerospace, construction, agricultural machinery and similar industries are leading to dramatic changes in product development and the resulting challenges. The complexity of products is increasing rapidly, mainly due to new functions and performance features supported by E/E systems. At the same time, development cycles are shortening to keep up with the accelerating pace of change and innovation. Companies that cannot accelerate their product development for new product generations are falling behind.

An integrated, all-encompassing development environment for E/E systems supports companies in their efforts to overcome complexity and accelerate time to market. Capital from Siemens Digital Industries Software provides unparalleled breadth to drive the development of electrical distribution systems, networks and embedded software, and enable the delivery of results for manufacturing and product service from within the E/E architecture.

In a white paper (available via the link below), Siemens presents its tight integration of mechanical, PLM, simulation and manufacturing planning solutions as part of the Siemens Xcelerator portfolio. This is intended to support the principles of model-based system design in the development of E/E systems, which contributes to the creation of a holistic digital twin of the product and manufacturing methodology.