UK-based Taylor Dowding Innovation (TDI) specializes in the development of electronic systems as components of end products. The company is also frequently entrusted with the procurement of electronic components and the awarding of contracts for PCB production. The PADS Professional App Suite has improved collaborative design processes.

Ben Dowding, CEO and Lead Engineer, Taylor Dowding Innovation Ltd.Ben Dowding, Chief Executive Officer (CEO) and Lead Engineer, sees TDI as an electronic design and software development services consultancy that tackles complex design problems on a daily basis. Founded in 2013, the company coordinates all processes with subcontractors - including those responsible for developing and manufacturing the housings for the end products. In addition, TDI also offers services to help system companies build their in-house engineering teams, tool workflows and procedures to develop future projects in-house.

Ben Dowding, CEO and Lead Engineer, Taylor Dowding Innovation Ltd.Ben Dowding, Chief Executive Officer (CEO) and Lead Engineer, sees TDI as an electronic design and software development services consultancy that tackles complex design problems on a daily basis. Founded in 2013, the company coordinates all processes with subcontractors - including those responsible for developing and manufacturing the housings for the end products. In addition, TDI also offers services to help system companies build their in-house engineering teams, tool workflows and procedures to develop future projects in-house.

"Every job is different and there are very different levels of experience and knowledge among clients," says Ben Dowding. "But quite a few of the companies we work with have no experience in this area. That's why tools for efficient communication and collaboration in design are a must."

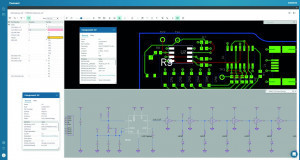

For PCB development, Ben Dowding is a long-time user of Siemens EDA's PADS Professional software. This software is part of the Xcelerator portfolio, a comprehensive and integrated collection of software and services from Siemens Digital Industries Software. Building on this experience, Ben Dowding recently decided to be one of the early adopters of the PADS Professional App Suite - a new cloud-based solution that is part of the evolving Xcelerator-as-a-Service (XaaS) offering.

The Professional App Suite is the first Siemens EDA technology to provide cloud-based SaaS for design teams. The suite offers a new level of productivity and collaboration between team members, parts suppliers and contract manufacturers, according to Siemens EDA.

The manufacturer plans to introduce additional configurations for new subscription plans in the future, giving its XaaS offering even tighter integration, expanded functionality and new higher levels of productivity.

Increased design efficiency

Ben Dowding describes that before deploying the suite, TDI typically used files that were accessible to multiple users via a shared link in a repository at a file hosting service. Another common solution was to email the project as a zip file.

The PADS Professional App Suite expands the possibilities of engineers through its cloud-based productivity"These approaches naturally brought their own problems, especially because data volumes or file sizes were constantly increasing." Ben Dowding: "You have to be very careful to ensure that everyone involved always receives the latest email and that everyone is actually working with the latest version of the design data." With this way of working, an email can easily get stuck at a firewall. "Then you either don't receive a reply at all or have to wait several days for it - even though it might only have taken 10 minutes to reply." Another issue is that "we all have to think about the security of data, for the transmission of which emails are not really reliable. All traditional methods have their limits here."

The PADS Professional App Suite expands the possibilities of engineers through its cloud-based productivity"These approaches naturally brought their own problems, especially because data volumes or file sizes were constantly increasing." Ben Dowding: "You have to be very careful to ensure that everyone involved always receives the latest email and that everyone is actually working with the latest version of the design data." With this way of working, an email can easily get stuck at a firewall. "Then you either don't receive a reply at all or have to wait several days for it - even though it might only have taken 10 minutes to reply." Another issue is that "we all have to think about the security of data, for the transmission of which emails are not really reliable. All traditional methods have their limits here."

When using the PADS Professional App Suite, on the other hand, everyone is truly networked: "We can all assume that we always have the latest design data." There are no longer any doubts about the integrity of the data, which is a step forward compared to the usual methods. Ben Dowding also explained that the use of the new suite helps his design team to reach a whole new level in terms of collaboration between the PCB development team members and their resulting productivity.

"I work closely with two colleagues, one of whom uses our floating license, while the other has his own PADS Professional license and often works remotely. Now, instead of keeping a design project on a standard file hosting service or creating some kind of repository for it, we can use the PADS Professional App Suite to create and discuss aspects of a design in a live environment. This allows us to approach our design process much more simultaneously than we ever could before." Even the check-in and check-out of the project is much smoother and more user-friendly.

According to Ben Dowding, this way of working gives you the feeling of working "side by side with another engineer" - for example, a PCB area can be marked and then examined in detail by the designer with regard to the relevant components in the web browser.

On the basis of a snapshot of this area, it is possible to work on adding tracking there. "But there's this mounting hole that's problematic. Can we move it?" Ben Dowding: "The collaborative way of working means that the engineer can get back to you with an answer to your question within a very short time." This enables the PCB designer to work more efficiently and stay on task. This ensures consistent, optimum productivity.

Promoting collaboration with customers and contractors

The company boss also noted that using the PADS Professional App Suite also makes it easier to share information with customers who would like to check the current schematic after design changes or bill of materials (BOM) modifications due to changes in the object library. "For example, we are working with a company in the aerospace industry that has developed a video system to be sent into space. It was great for them to be able to see the 3D representation of the product at the same time as we were working on its design," says Dowding.

The ability to access the latest version of the design at any time and share detailed information also applies to collaboration with mechanical CAD (MCAD) teams.

"Even though the MCAD teams often don't have a PADS Professional license, I can share the design with them using the suite," says Dowding. "This gives them much more detailed PCB design information to refine their enclosure design at the same time. In the collaboration workspace within the PADS Professional App Suite, you can publish information that is immediately accessible to the other teams. They can then access it extremely quickly."

Software reliability and data security

The CEO emphasizes that he also works with clients from sensitive industries where data security is a key concern. "On behalf of my clients, I need to ensure the integrity of their data and a secure overview of who has access to that data." These problems are solved by the PADS Professional App Suite. "The sense of security that comes from this product and the ability to enable or disable access for your clients or your team members via remote access control is very good and flexible. I know that every system has potential weaknesses. But as far as I can tell so far, the suite is extremely secure."

Before switching to the PADS Professional App Suite, TDI already had some experience with a competitor's cloud-based technology - not so good, he notes. "There were timing issues with the competitor's product, which led to a lot of pressure to achieve end results." The workstation environment was exceptionally slow in terms of library development and also updating some design files. "When I encountered bugs in this software, I expected them to be fixed quickly. Unfortunately, that was not the case with this provider." Dowding has since resolved not to use any more circuit design software platforms "where the vendor doesn't seem to value me as a customer."

When he switched to the PADS Professional Suite, he immediately noticed the increased efficiency, productivity and quality that this tool had to offer. "After that, I didn't want to waste my time doing something with less productivity than I could with another, better tool." The PADS Professional App Suite now offers TDI and its partners significantly faster and better results combined with increased ease of use.

Given this high reliability and better performance compared to competing products, it's easy to see why this new solution has immediately become the preferred tool of the team and customer network. "The combination of improved design efficiency, enhanced design data security and simultaneous engineering in a reliable cloud environment leads to faster time to market and happier customers," says Dowding. Furthermore, as part of the Xcelerator SaaS portfolio, the suite now also provides these benefits for the entire development and manufacturing process. It seamlessly connects component suppliers, PCB manufacturers and mechanical engineers in a digital way.

Core business development partnership

Taylor Dowding Innovation Limited provides electronic product development and specialist engineering consultancy services from its base in Ness, Cheshire, UK, on the Wirral Peninsula in North West England. Established in 2013, TDI works closely with customers across the UK and abroad to develop high performance, cost effective and robust advanced technology products.